What is Global Mobile Cold Spray System Market?

The Global Mobile Cold Spray System Market refers to the industry focused on the development, production, and application of mobile cold spray systems. These systems are advanced technologies used for coating surfaces with metals and other materials without the need for high temperatures. Unlike traditional thermal spray methods, cold spray technology operates at lower temperatures, which helps in preserving the properties of the substrate material and reducing oxidation. This market is driven by the demand for efficient and environmentally friendly coating solutions across various industries. Mobile cold spray systems are particularly valued for their portability, allowing for on-site repairs and maintenance, which is crucial in sectors like aerospace, defense, and automotive. The market is expanding as industries seek to enhance the durability and performance of their components while minimizing downtime and costs associated with traditional repair methods. The versatility and efficiency of mobile cold spray systems make them an attractive option for industries looking to improve their operational efficiency and product longevity. As technology advances, the market is expected to grow, driven by innovations that enhance the capabilities and applications of cold spray systems.

High-Pressure Systems, Low-Pressure Systems in the Global Mobile Cold Spray System Market:

High-pressure and low-pressure systems are two primary types of mobile cold spray systems, each with distinct characteristics and applications within the Global Mobile Cold Spray System Market. High-pressure systems operate at pressures typically above 300 psi and are designed to accelerate particles to supersonic speeds. This high velocity allows for the deposition of dense and strong coatings, making them ideal for applications requiring high bond strength and wear resistance. High-pressure systems are often used in industries where the integrity of the coating is critical, such as aerospace and defense, where components are subjected to extreme conditions. The ability to deposit a wide range of materials, including metals, ceramics, and composites, further enhances their versatility. These systems are also favored for their ability to repair and restore components without causing thermal damage, preserving the original properties of the substrate. On the other hand, low-pressure systems operate at pressures below 300 psi and are typically used for applications where less aggressive deposition is required. These systems are more suited for softer materials and applications where the substrate may be sensitive to high impact forces. Low-pressure systems are often used in the automotive and energy sectors, where they provide effective coatings for corrosion resistance and surface restoration. The lower pressure and velocity in these systems result in a more gentle deposition process, which can be advantageous for delicate components or when working with materials that may be prone to deformation under high impact. Additionally, low-pressure systems are generally more cost-effective and easier to operate, making them accessible for a wider range of applications and industries. Both high-pressure and low-pressure systems have their unique advantages and are chosen based on the specific requirements of the application. High-pressure systems are preferred for their ability to produce high-quality, durable coatings that can withstand harsh environments, while low-pressure systems offer a more economical and versatile solution for less demanding applications. The choice between the two often depends on factors such as the type of material being deposited, the desired properties of the coating, and the operational constraints of the application. As the Global Mobile Cold Spray System Market continues to evolve, advancements in technology are likely to enhance the capabilities of both high-pressure and low-pressure systems, expanding their range of applications and improving their efficiency and effectiveness.

Aerospace, Defense, Automotive, Energy, Other in the Global Mobile Cold Spray System Market:

The Global Mobile Cold Spray System Market finds extensive usage across various industries, including aerospace, defense, automotive, energy, and others, due to its ability to provide high-quality coatings and repairs without the need for high temperatures. In the aerospace industry, mobile cold spray systems are used for repairing and maintaining aircraft components, such as turbine blades and landing gear, which are subject to extreme conditions and wear. The ability to perform on-site repairs reduces downtime and costs associated with transporting components to specialized facilities. In the defense sector, these systems are employed for the maintenance and repair of military equipment, including vehicles and weaponry, where durability and reliability are paramount. The cold spray process allows for the restoration of components without compromising their structural integrity, which is crucial for maintaining operational readiness. In the automotive industry, mobile cold spray systems are used for coating and repairing engine components, exhaust systems, and body panels. The process provides corrosion resistance and enhances the longevity of parts, contributing to improved vehicle performance and reduced maintenance costs. The energy sector also benefits from mobile cold spray systems, particularly in the maintenance of pipelines, turbines, and other critical infrastructure. The ability to apply coatings that resist corrosion and wear extends the lifespan of these components, ensuring efficient and reliable energy production and distribution. Other industries, such as electronics and manufacturing, also utilize mobile cold spray systems for various applications, including the deposition of conductive coatings and the repair of machinery and equipment. The versatility and efficiency of mobile cold spray systems make them an attractive option for industries looking to improve their operational efficiency and product longevity. The ability to perform on-site repairs and apply high-quality coatings without the need for high temperatures or extensive downtime is a significant advantage, particularly in industries where time and cost are critical factors. As technology advances, the range of applications for mobile cold spray systems is expected to expand, driven by innovations that enhance their capabilities and performance. The Global Mobile Cold Spray System Market is poised for growth as industries continue to seek efficient and environmentally friendly solutions for coating and repairing components.

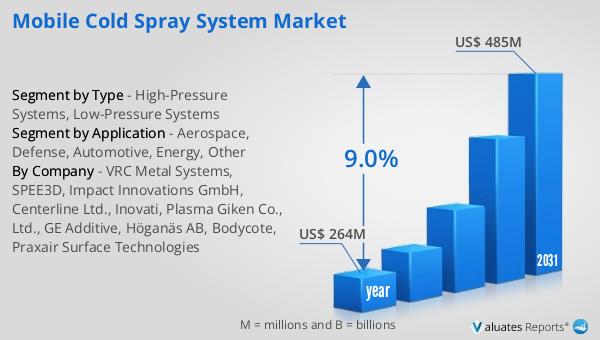

Global Mobile Cold Spray System Market Outlook:

The global market for Mobile Cold Spray System was valued at approximately $264 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $485 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 9.0% over the forecast period. This upward trend is indicative of the increasing demand for mobile cold spray systems across various industries, driven by their ability to provide efficient, high-quality coatings and repairs without the need for high temperatures. The market's expansion is fueled by the growing need for cost-effective and environmentally friendly solutions that enhance the durability and performance of components while minimizing downtime and maintenance costs. As industries continue to prioritize operational efficiency and sustainability, the adoption of mobile cold spray systems is expected to rise, contributing to the market's robust growth. The projected growth of the Global Mobile Cold Spray System Market underscores the importance of this technology in meeting the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Mobile Cold Spray System Market |

| Accounted market size in year | US$ 264 million |

| Forecasted market size in 2031 | US$ 485 million |

| CAGR | 9.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | VRC Metal Systems, SPEE3D, Impact Innovations GmbH, Centerline Ltd., Inovati, Plasma Giken Co., Ltd., GE Additive, Höganäs AB, Bodycote, Praxair Surface Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |