What is Global Assembly Line for Pouch Cell Production Market?

The Global Assembly Line for Pouch Cell Production Market is a specialized sector within the broader battery manufacturing industry. This market focuses on the production of pouch cells, which are a type of lithium-ion battery known for their lightweight, flexible packaging and high energy density. Pouch cells are increasingly popular due to their adaptability in various applications, from consumer electronics to electric vehicles. The assembly line for pouch cell production involves a series of automated processes designed to enhance efficiency, precision, and scalability. These processes include electrode preparation, cell stacking, electrolyte filling, sealing, and testing. The global market for these assembly lines is driven by the growing demand for energy-efficient and compact power sources. As industries continue to innovate and expand their use of portable and rechargeable devices, the need for advanced pouch cell production capabilities becomes more critical. This market is characterized by technological advancements, increased automation, and a focus on reducing production costs while maintaining high-quality standards. The ongoing research and development efforts aim to improve the performance and longevity of pouch cells, further fueling the growth of this market.

Small-scale Trial Line, Pilot-scale Production Line, Mass Production Line in the Global Assembly Line for Pouch Cell Production Market:

In the Global Assembly Line for Pouch Cell Production Market, there are three primary types of production lines: small-scale trial lines, pilot-scale production lines, and mass production lines. Each serves a distinct purpose and caters to different stages of product development and market demand. Small-scale trial lines are typically used in the initial stages of product development. They allow manufacturers to experiment with new materials, designs, and processes on a limited scale. These lines are crucial for testing the feasibility and performance of new pouch cell technologies before committing to larger-scale production. The flexibility of small-scale trial lines enables rapid prototyping and iteration, which is essential for innovation in the fast-paced battery industry. Pilot-scale production lines represent the next step in the development process. These lines are larger than small-scale trial lines and are designed to produce a limited quantity of pouch cells for further testing and validation. Pilot-scale lines help manufacturers refine their production processes and ensure that the cells meet the necessary quality and performance standards. This stage is critical for identifying potential issues and making adjustments before scaling up to mass production. Mass production lines are the largest and most complex type of assembly line in the pouch cell production market. These lines are designed for high-volume manufacturing and are equipped with advanced automation technologies to maximize efficiency and output. Mass production lines are essential for meeting the growing demand for pouch cells in various industries, including consumer electronics, electric vehicles, and energy storage systems. The transition from pilot-scale to mass production requires significant investment in infrastructure and technology, but it is necessary to achieve economies of scale and competitive pricing. Each type of production line plays a vital role in the lifecycle of pouch cell development, from initial concept to full-scale commercialization. The ability to seamlessly transition between these stages is crucial for manufacturers looking to stay competitive in the rapidly evolving battery market. As the demand for high-performance, reliable pouch cells continues to rise, the importance of efficient and adaptable assembly lines becomes increasingly apparent. Manufacturers must invest in state-of-the-art equipment and processes to ensure they can meet the needs of their customers while maintaining high standards of quality and sustainability.

Consumer Electronics, Electric Vehicles, Energy Storage Systems, Others in the Global Assembly Line for Pouch Cell Production Market:

The Global Assembly Line for Pouch Cell Production Market plays a significant role in several key areas, including consumer electronics, electric vehicles, energy storage systems, and other applications. In consumer electronics, pouch cells are widely used due to their compact size and high energy density. Devices such as smartphones, tablets, laptops, and wearable technology rely on these batteries to provide long-lasting power in a lightweight package. The demand for portable and efficient power sources in consumer electronics drives the need for advanced pouch cell production capabilities. As technology continues to evolve, the requirements for battery performance and longevity increase, making the assembly line for pouch cell production a critical component of the supply chain. In the electric vehicle (EV) sector, pouch cells are favored for their ability to deliver high power output and energy efficiency. The automotive industry is rapidly transitioning towards electrification, and the demand for reliable, high-capacity batteries is at an all-time high. Pouch cells offer a flexible design that can be tailored to fit the specific requirements of different vehicle models, making them an attractive option for EV manufacturers. The assembly line for pouch cell production must be capable of producing large volumes of high-quality cells to meet the growing needs of the EV market. Energy storage systems (ESS) also benefit from the advancements in pouch cell production. These systems are used to store energy generated from renewable sources such as solar and wind power, providing a stable and reliable power supply. Pouch cells are ideal for ESS applications due to their high energy density and ability to withstand frequent charge and discharge cycles. The global push towards renewable energy and sustainability has increased the demand for efficient energy storage solutions, further driving the growth of the pouch cell production market. In addition to these primary areas, pouch cells are used in various other applications, including medical devices, aerospace, and industrial equipment. The versatility and adaptability of pouch cells make them suitable for a wide range of uses, and the assembly line for their production must be equally versatile to accommodate different specifications and requirements. As industries continue to innovate and expand their use of battery-powered devices, the importance of efficient and reliable pouch cell production becomes increasingly evident. Manufacturers must invest in cutting-edge technology and processes to ensure they can meet the diverse needs of their customers while maintaining high standards of quality and sustainability.

Global Assembly Line for Pouch Cell Production Market Outlook:

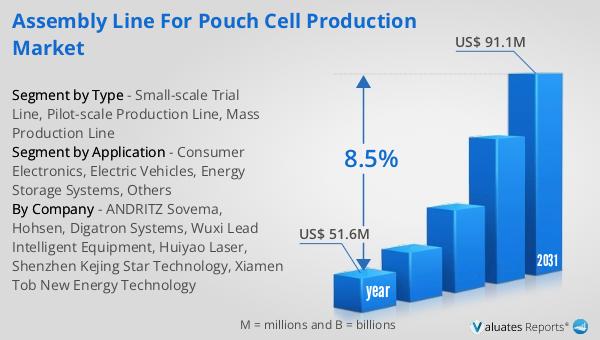

The global market for assembly lines dedicated to pouch cell production was valued at approximately $51.6 million in 2024. This market is anticipated to grow significantly, reaching an estimated value of $91.1 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.5% over the forecast period. The increasing demand for pouch cells across various industries, including consumer electronics, electric vehicles, and energy storage systems, is a key driver of this market expansion. As the need for efficient, high-capacity batteries continues to rise, manufacturers are investing in advanced assembly line technologies to enhance production capabilities and meet market demands. The projected growth of the pouch cell production market underscores the importance of innovation and efficiency in battery manufacturing. Companies are focusing on developing state-of-the-art assembly lines that incorporate automation and precision engineering to optimize production processes. This investment in technology not only improves the quality and performance of pouch cells but also reduces production costs, making them more accessible to a broader range of applications. As the market continues to evolve, the emphasis on sustainability and environmental responsibility will also play a crucial role in shaping the future of pouch cell production.

| Report Metric | Details |

| Report Name | Assembly Line for Pouch Cell Production Market |

| Accounted market size in year | US$ 51.6 million |

| Forecasted market size in 2031 | US$ 91.1 million |

| CAGR | 8.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ANDRITZ Sovema, Hohsen, Digatron Systems, Wuxi Lead Intelligent Equipment, Huiyao Laser, Shenzhen Kejing Star Technology, Xiamen Tob New Energy Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |