What is Global Combined Type Needle Roller Bearings Market?

The Global Combined Type Needle Roller Bearings Market refers to the worldwide industry focused on the production, distribution, and application of combined type needle roller bearings. These bearings are specialized components used in various mechanical systems to reduce friction between moving parts and support radial and axial loads. They are called "combined type" because they integrate needle rollers with other types of rolling elements, such as ball bearings or cylindrical rollers, to enhance their load-bearing capacity and performance. The market for these bearings is driven by their widespread use in industries such as automotive, construction machinery, and aerospace, where they are valued for their ability to handle high-speed operations and heavy loads while maintaining precision and durability. The global demand for these bearings is influenced by factors such as technological advancements, industrial growth, and the increasing need for efficient and reliable machinery components. As industries continue to evolve and seek more efficient solutions, the market for combined type needle roller bearings is expected to grow, offering opportunities for manufacturers and suppliers to innovate and meet the diverse needs of their customers.

in the Global Combined Type Needle Roller Bearings Market:

The Global Combined Type Needle Roller Bearings Market offers a variety of types to cater to the diverse needs of customers across different industries. These bearings are designed to provide optimal performance in specific applications, and their selection depends on factors such as load capacity, speed, and environmental conditions. One common type is the needle roller and cage assemblies, which consist of a cage that holds and guides the needle rollers. This type is known for its high load-carrying capacity and is often used in applications where space is limited. Another type is the drawn cup needle roller bearings, which feature a thin-walled outer ring and are ideal for applications requiring compact and lightweight components. These bearings are commonly used in automotive transmissions and gearboxes due to their ability to handle high speeds and radial loads. Additionally, there are thrust needle roller bearings, which are designed to support axial loads and are often used in combination with radial needle roller bearings to accommodate both radial and axial forces. These are typically found in automotive and industrial machinery applications where axial space is limited. Furthermore, there are combined needle roller bearings, which integrate needle rollers with other types of rolling elements, such as ball bearings or cylindrical rollers. This combination enhances the bearing's load-bearing capacity and allows it to handle both radial and axial loads simultaneously. These bearings are widely used in construction machinery and heavy-duty applications where robust performance is required. The market also includes customized needle roller bearings, which are tailored to meet specific customer requirements. These bearings are designed to address unique challenges and provide solutions for specialized applications. Manufacturers work closely with customers to develop bearings that meet their exact specifications, ensuring optimal performance and reliability. The availability of various types of combined needle roller bearings allows customers to choose the most suitable option for their specific needs, ensuring efficient and reliable operation of their machinery and equipment. As industries continue to evolve and demand more advanced solutions, the market for these bearings is expected to grow, offering opportunities for innovation and development of new types to meet emerging needs.

Automotive, Construction Machinery, Aerospace, Others in the Global Combined Type Needle Roller Bearings Market:

The Global Combined Type Needle Roller Bearings Market plays a crucial role in various industries, including automotive, construction machinery, aerospace, and others. In the automotive sector, these bearings are essential components in transmissions, gearboxes, and engines, where they help reduce friction and support high-speed operations. Their ability to handle both radial and axial loads makes them ideal for use in vehicles, where space is limited, and performance is critical. In construction machinery, combined type needle roller bearings are used in equipment such as excavators, cranes, and loaders. These machines require robust and durable components to withstand harsh operating conditions and heavy loads. The bearings' high load-carrying capacity and ability to operate in challenging environments make them suitable for construction applications. In the aerospace industry, these bearings are used in aircraft engines, landing gear, and other critical systems. The aerospace sector demands components that offer high precision, reliability, and performance under extreme conditions. Combined type needle roller bearings meet these requirements, providing the necessary support for safe and efficient aircraft operation. Additionally, these bearings are used in various other industries, such as industrial machinery, medical equipment, and renewable energy. In industrial machinery, they are used in applications such as pumps, compressors, and conveyor systems, where they help improve efficiency and reduce maintenance costs. In medical equipment, these bearings are used in devices such as MRI machines and surgical instruments, where precision and reliability are paramount. In the renewable energy sector, they are used in wind turbines and solar tracking systems, where they contribute to the efficient generation of clean energy. The versatility and performance of combined type needle roller bearings make them indispensable in a wide range of applications, driving their demand across multiple industries. As these industries continue to grow and evolve, the market for these bearings is expected to expand, offering opportunities for manufacturers to innovate and develop new solutions to meet the changing needs of their customers.

Global Combined Type Needle Roller Bearings Market Outlook:

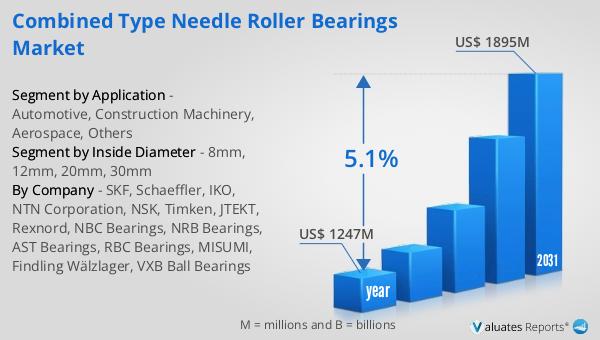

The global market for Combined Type Needle Roller Bearings was valued at approximately $1,247 million in 2024. It is anticipated to grow significantly, reaching an estimated size of $1,895 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.1% over the forecast period. This upward trend indicates a robust demand for these specialized bearings across various industries. The increasing need for efficient and reliable machinery components in sectors such as automotive, construction, and aerospace is a key driver of this market growth. As industries continue to advance and seek more efficient solutions, the demand for combined type needle roller bearings is expected to rise. This growth presents opportunities for manufacturers and suppliers to innovate and meet the diverse needs of their customers. The market's expansion is also influenced by technological advancements and industrial growth, which are driving the demand for high-performance bearings. As a result, the global market for combined type needle roller bearings is poised for significant growth, offering opportunities for manufacturers and suppliers to capitalize on the increasing demand for these essential components.

| Report Metric | Details |

| Report Name | Combined Type Needle Roller Bearings Market |

| Accounted market size in year | US$ 1247 million |

| Forecasted market size in 2031 | US$ 1895 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Inside Diameter |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SKF, Schaeffler, IKO, NTN Corporation, NSK, Timken, JTEKT, Rexnord, NBC Bearings, NRB Bearings, AST Bearings, RBC Bearings, MISUMI, Findling Wälzlager, VXB Ball Bearings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |