What is Global AMR Warehouse Robot Market?

The Global AMR (Autonomous Mobile Robot) Warehouse Robot Market is a rapidly evolving sector that focuses on the deployment of intelligent robots in warehouse environments to enhance efficiency and productivity. These robots are designed to navigate autonomously within warehouse settings, performing tasks such as picking, sorting, and transporting goods. The market is driven by the increasing demand for automation in logistics and supply chain operations, as businesses seek to optimize their processes and reduce labor costs. AMR warehouse robots are equipped with advanced sensors and software that allow them to operate safely alongside human workers, adapting to dynamic environments and making real-time decisions. The adoption of these robots is further fueled by the growth of e-commerce, which requires faster and more efficient order fulfillment. As technology continues to advance, the capabilities of AMR warehouse robots are expected to expand, offering even greater benefits to businesses in terms of operational efficiency and cost savings. The market is characterized by a diverse range of robot types and applications, catering to various industry needs and preferences. Overall, the Global AMR Warehouse Robot Market represents a significant opportunity for innovation and growth in the field of warehouse automation.

Laser SLAM Navigation, Visual SLAM Navigation in the Global AMR Warehouse Robot Market:

Laser SLAM (Simultaneous Localization and Mapping) Navigation and Visual SLAM Navigation are two pivotal technologies in the Global AMR Warehouse Robot Market, each offering unique advantages for autonomous navigation. Laser SLAM Navigation utilizes laser sensors to create a map of the environment while simultaneously determining the robot's position within that map. This method is highly accurate and reliable, making it ideal for environments where precision is crucial. Laser sensors can detect obstacles and measure distances with high accuracy, allowing robots to navigate complex warehouse layouts efficiently. The technology is particularly beneficial in large warehouses with static layouts, where the environment does not change frequently. On the other hand, Visual SLAM Navigation relies on cameras and computer vision algorithms to achieve the same goal of mapping and localization. This approach is more flexible and adaptable to dynamic environments, as it can recognize and adapt to changes in the surroundings. Visual SLAM is advantageous in settings where the environment is constantly changing, such as in warehouses with frequently moving inventory or where the layout is regularly reconfigured. The use of cameras allows robots to gather rich visual information, which can be used for tasks beyond navigation, such as identifying specific items or reading labels. Both Laser SLAM and Visual SLAM have their own set of challenges. Laser SLAM can be limited by the range and field of view of the laser sensors, and it may struggle in environments with reflective surfaces that can distort laser readings. Visual SLAM, while more adaptable, can be computationally intensive and may require significant processing power to analyze visual data in real-time. Additionally, lighting conditions can affect the performance of Visual SLAM, as poor lighting can hinder the robot's ability to capture clear images. Despite these challenges, both technologies are continually evolving, with ongoing research and development aimed at overcoming their limitations. In the context of the Global AMR Warehouse Robot Market, the choice between Laser SLAM and Visual SLAM often depends on the specific requirements of the warehouse environment and the tasks the robots are expected to perform. Some advanced AMR systems even integrate both technologies, leveraging the strengths of each to achieve optimal performance. As the demand for warehouse automation grows, the development and refinement of SLAM technologies will play a crucial role in shaping the future of autonomous mobile robots. The integration of artificial intelligence and machine learning with SLAM technologies is also expected to enhance the capabilities of AMR systems, enabling them to learn from their experiences and improve their performance over time. This continuous improvement will further drive the adoption of AMR warehouse robots, as businesses seek to capitalize on the benefits of automation in an increasingly competitive market.

Warehousing, Logistics, Factory, Retail, Others in the Global AMR Warehouse Robot Market:

The usage of Global AMR Warehouse Robots spans across various sectors, including warehousing, logistics, factories, retail, and others, each benefiting from the unique capabilities of these autonomous systems. In warehousing, AMR robots are primarily used to streamline operations by automating the movement of goods within the facility. They can efficiently transport items from one location to another, reducing the need for manual labor and minimizing the risk of human error. This automation leads to faster order fulfillment and improved inventory management, which are critical in meeting the demands of modern supply chains. In logistics, AMR robots play a crucial role in optimizing the flow of goods throughout the supply chain. They can be deployed in distribution centers to handle tasks such as sorting and loading, ensuring that products are delivered to their destinations promptly and accurately. The flexibility of AMR systems allows them to adapt to different logistics environments, making them a valuable asset for companies looking to enhance their operational efficiency. In factory settings, AMR robots are used to automate material handling processes, such as transporting raw materials to production lines or moving finished products to storage areas. This automation not only increases productivity but also enhances workplace safety by reducing the need for human workers to perform potentially hazardous tasks. In the retail sector, AMR robots are employed to improve the efficiency of in-store operations. They can assist with tasks such as restocking shelves, managing inventory, and even providing customer service. By automating these processes, retailers can focus on enhancing the customer experience and driving sales. Beyond these sectors, AMR robots are also finding applications in other areas, such as healthcare and agriculture, where they are used to automate tasks like transporting medical supplies or assisting with crop harvesting. The versatility of AMR systems makes them suitable for a wide range of applications, and their adoption is expected to continue growing as businesses across various industries recognize the benefits of automation. Overall, the Global AMR Warehouse Robot Market is transforming the way businesses operate, offering significant advantages in terms of efficiency, productivity, and cost savings.

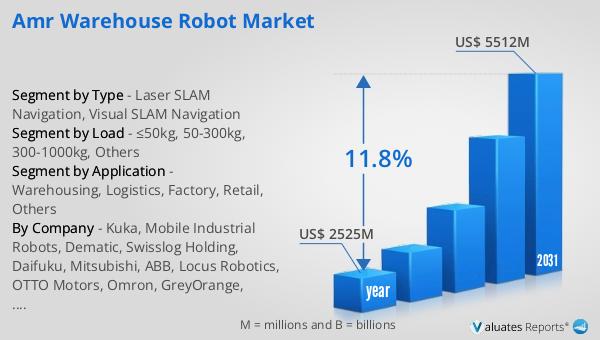

Global AMR Warehouse Robot Market Outlook:

The global market for AMR Warehouse Robots was valued at $2,525 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $5,512 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 11.8% over the forecast period. This impressive growth can be attributed to the increasing demand for automation in warehouse operations, driven by the need for greater efficiency and cost-effectiveness. As businesses strive to optimize their supply chain processes, the adoption of AMR warehouse robots is becoming increasingly prevalent. These robots offer a range of benefits, including improved accuracy, faster order fulfillment, and enhanced safety, all of which contribute to their growing popularity. The market's expansion is also supported by advancements in technology, such as the development of more sophisticated sensors and navigation systems, which enhance the capabilities of AMR robots. Additionally, the rise of e-commerce and the need for rapid order processing are further fueling the demand for warehouse automation solutions. As a result, the Global AMR Warehouse Robot Market is poised for continued growth, offering significant opportunities for innovation and investment in the coming years.

| Report Metric | Details |

| Report Name | AMR Warehouse Robot Market |

| Accounted market size in year | US$ 2525 million |

| Forecasted market size in 2031 | US$ 5512 million |

| CAGR | 11.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Load |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kuka, Mobile Industrial Robots, Dematic, Swisslog Holding, Daifuku, Mitsubishi, ABB, Locus Robotics, OTTO Motors, Omron, GreyOrange, Swisslog, Amazon, Hai Robotics, Innovix Robotics, Megvii, Syrius Robotics, Beacon Robot, Iplusmobot, Yufeng Intelligent, Gen-song, ForwardX Robotics, Geekplus Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |