What is Global Industrial Pin Mill Market?

The Global Industrial Pin Mill Market refers to the worldwide industry focused on the production and sale of pin mills, which are machines used for grinding and pulverizing materials into fine powders. These mills are essential in various industries due to their ability to efficiently reduce particle sizes, making them crucial for processes that require fine and uniform particle distribution. Pin mills operate by using two discs with pins that rotate in opposite directions, creating a shearing and impact force that breaks down the material. The market for these mills is driven by the demand from sectors such as food processing, pharmaceuticals, chemicals, and minerals, where precise particle size reduction is necessary. As industries continue to grow and innovate, the need for efficient and reliable grinding solutions like pin mills is expected to rise, making this market an important component of the global industrial machinery landscape.

Horizontal, Vertical in the Global Industrial Pin Mill Market:

In the Global Industrial Pin Mill Market, pin mills are categorized based on their orientation into horizontal and vertical types, each serving distinct purposes and offering unique advantages. Horizontal pin mills are designed with a horizontal shaft, which allows for a more straightforward and compact design. This orientation is particularly beneficial for applications where space is limited, as horizontal mills can be easily integrated into existing production lines without requiring significant modifications. The horizontal design also facilitates easier maintenance and cleaning, as the components are more accessible. These mills are often used in industries where the processing of dry, brittle materials is required, such as in the production of flour, sugar, and other powdered food products. The horizontal configuration allows for efficient grinding and uniform particle size distribution, which is crucial for maintaining product quality and consistency. On the other hand, vertical pin mills feature a vertical shaft, which provides a different set of advantages. The vertical orientation allows for a more efficient use of gravity, aiding in the movement of materials through the mill. This can result in higher throughput rates and improved energy efficiency, as the natural force of gravity assists in the grinding process. Vertical pin mills are particularly well-suited for applications involving wet or sticky materials, as the vertical design helps prevent clogging and ensures a smooth flow of materials. This makes them ideal for use in the chemical and pharmaceutical industries, where the processing of viscous or heat-sensitive materials is common. Additionally, the vertical design can offer better cooling capabilities, which is important for preventing heat buildup during the grinding process. Both horizontal and vertical pin mills are equipped with a variety of features to enhance their performance and adaptability. These features may include adjustable pin configurations, which allow for customization of the grinding process to achieve the desired particle size and distribution. Some models also offer variable speed controls, enabling operators to fine-tune the milling process for different materials and applications. Furthermore, advanced models may incorporate automation and control systems, providing real-time monitoring and adjustments to optimize performance and efficiency. The choice between horizontal and vertical pin mills ultimately depends on the specific requirements of the application and the characteristics of the materials being processed. Factors such as space constraints, material properties, and desired output quality all play a role in determining the most suitable type of pin mill for a given operation. As industries continue to evolve and demand more efficient and versatile grinding solutions, manufacturers are continually innovating and improving the design and capabilities of both horizontal and vertical pin mills to meet these needs. In summary, the Global Industrial Pin Mill Market offers a range of options for businesses seeking efficient and reliable grinding solutions. Whether opting for a horizontal or vertical design, pin mills provide the versatility and performance needed to meet the diverse demands of modern industrial processes. As technology advances and industries continue to grow, the importance of choosing the right pin mill configuration will remain a critical factor in achieving operational success and maintaining a competitive edge in the market.

Minerals, Chemicals, Food and Pharmaceuticals, Others in the Global Industrial Pin Mill Market:

The Global Industrial Pin Mill Market finds extensive usage across various sectors, including minerals, chemicals, food and pharmaceuticals, and others, due to its ability to efficiently reduce particle sizes and produce fine powders. In the minerals industry, pin mills are used to grind and pulverize a wide range of materials, including ores, rocks, and minerals, to achieve the desired particle size for further processing or direct application. The ability to produce uniform and fine particles is crucial in the minerals sector, as it affects the efficiency of subsequent processes such as flotation, leaching, and smelting. Pin mills offer the advantage of high throughput rates and energy efficiency, making them a preferred choice for mineral processing operations. In the chemicals industry, pin mills are employed to process a variety of chemical compounds, including pigments, dyes, and resins. The precise particle size reduction achieved by pin mills is essential for ensuring the quality and performance of chemical products. For instance, in the production of pigments, achieving the right particle size is critical for color consistency and dispersion properties. Pin mills also play a vital role in the production of specialty chemicals, where precise control over particle size and distribution is necessary to meet specific application requirements. The versatility of pin mills allows them to handle a wide range of chemical materials, from dry powders to wet slurries, making them an indispensable tool in the chemical processing industry. In the food and pharmaceuticals sector, pin mills are used to process a variety of products, including spices, grains, and active pharmaceutical ingredients (APIs). In the food industry, pin mills are employed to grind spices and grains into fine powders, which are then used in the production of various food products. The ability to achieve uniform particle size distribution is crucial for maintaining product quality and consistency. In the pharmaceutical industry, pin mills are used to process APIs and excipients, ensuring that the final product meets the required specifications for particle size and distribution. The gentle grinding action of pin mills helps preserve the integrity of heat-sensitive materials, making them ideal for processing delicate pharmaceutical compounds. Beyond these primary sectors, pin mills are also used in other industries, such as cosmetics, plastics, and agriculture. In the cosmetics industry, pin mills are used to produce fine powders for use in makeup and skincare products. In the plastics industry, pin mills are employed to grind plastic resins and additives, ensuring uniform particle size for optimal processing and product performance. In agriculture, pin mills are used to process animal feed and fertilizers, improving the efficiency and effectiveness of these products. Overall, the Global Industrial Pin Mill Market plays a crucial role in various industries by providing efficient and reliable grinding solutions. The versatility and performance of pin mills make them an essential tool for achieving the desired particle size and distribution in a wide range of applications. As industries continue to evolve and demand more precise and efficient processing solutions, the importance of pin mills in the global market is expected to grow.

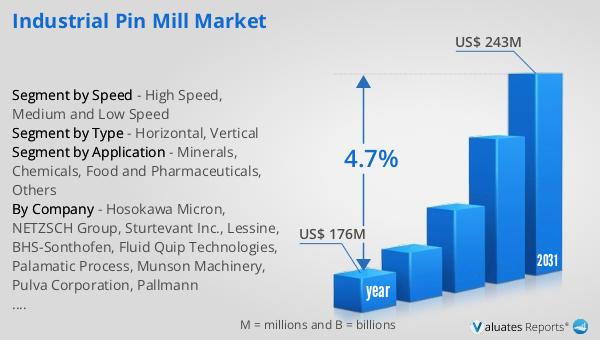

Global Industrial Pin Mill Market Outlook:

The global market for Industrial Pin Mills was valued at $176 million in 2024, and it is anticipated to expand to a revised size of $243 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.7% over the forecast period. This growth trajectory underscores the increasing demand for pin mills across various industries, driven by the need for efficient and precise particle size reduction solutions. As industries such as food processing, pharmaceuticals, chemicals, and minerals continue to expand and innovate, the requirement for reliable and versatile grinding equipment like pin mills is expected to rise. The projected growth in the market size indicates a robust demand for these machines, as businesses seek to enhance their production capabilities and maintain a competitive edge in their respective sectors. The steady CAGR of 4.7% highlights the consistent and sustained interest in pin mills, as they offer the performance and adaptability needed to meet the diverse demands of modern industrial processes. As the market continues to evolve, manufacturers are likely to focus on developing advanced pin mill technologies that offer improved efficiency, flexibility, and ease of use, further driving the growth of the global industrial pin mill market.

| Report Metric | Details |

| Report Name | Industrial Pin Mill Market |

| Accounted market size in year | US$ 176 million |

| Forecasted market size in 2031 | US$ 243 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Speed |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hosokawa Micron, NETZSCH Group, Sturtevant Inc., Lessine, BHS-Sonthofen, Fluid Quip Technologies, Palamatic Process, Munson Machinery, Pulva Corporation, Pallmann Maschinenfabrik, Yinda Machinery, EPIC Powder Machinery, JetmillMFG, Gotic Zerkleinerungstechnik, Chongqing Jiangbeimach |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |