What is Global Reflow Soldering Oven Market?

The Global Reflow Soldering Oven Market is a specialized segment within the electronics manufacturing industry, focusing on the equipment used for soldering electronic components onto printed circuit boards (PCBs). Reflow soldering ovens are essential in the assembly of electronic devices, as they ensure that components are securely attached to the PCBs through a process that involves heating solder paste to a temperature where it melts and forms a solid connection upon cooling. This market is driven by the increasing demand for electronic devices across various sectors, including consumer electronics, telecommunications, and automotive industries. As technology advances, the need for more efficient and precise soldering techniques grows, making reflow soldering ovens a critical component in the manufacturing process. The market is characterized by a variety of oven types, each offering different features and capabilities to meet the diverse needs of manufacturers. With the continuous evolution of electronic devices, the Global Reflow Soldering Oven Market is expected to expand, driven by innovations in oven technology and the growing complexity of electronic assemblies. This market plays a crucial role in ensuring the reliability and performance of electronic products, making it an integral part of the global electronics manufacturing landscape.

Convection Ovens, Vapour Phase Ovens, Others in the Global Reflow Soldering Oven Market:

In the Global Reflow Soldering Oven Market, convection ovens, vapor phase ovens, and other types of ovens play significant roles, each offering unique advantages and applications. Convection ovens are the most prevalent type, known for their efficiency and versatility. They use hot air to transfer heat to the solder paste, ensuring even temperature distribution across the PCB. This method is highly effective for mass production, as it allows for consistent results and can handle a wide range of board sizes and component types. Convection ovens are favored for their ability to maintain precise temperature control, which is crucial for preventing defects in solder joints. On the other hand, vapor phase ovens utilize a different approach by using a vaporized liquid to transfer heat. This method provides excellent heat transfer efficiency and is particularly beneficial for complex assemblies with high thermal mass components. Vapor phase ovens are known for their ability to minimize thermal stress on components, reducing the risk of damage during the soldering process. They are often used for specialized applications where precision and reliability are paramount. Other types of ovens in the market include infrared and laser reflow ovens, each offering distinct advantages. Infrared ovens use infrared radiation to heat the solder paste, providing rapid heating and cooling cycles. This method is suitable for applications requiring quick turnaround times and is often used in prototyping and small-scale production. Laser reflow ovens, although less common, offer precise control over the soldering process by using laser beams to selectively heat specific areas of the PCB. This technology is ideal for applications requiring high precision and minimal thermal impact on surrounding components. The choice of oven type depends on various factors, including the complexity of the assembly, production volume, and specific requirements of the end product. Manufacturers in the Global Reflow Soldering Oven Market continue to innovate, developing advanced features such as real-time monitoring, automated process control, and energy-efficient designs to meet the evolving needs of the electronics industry. As the demand for smaller, more powerful electronic devices grows, the market for reflow soldering ovens is expected to expand, driven by the need for more sophisticated and reliable soldering solutions.

Telecommunication, Consumer Electronics, Automotive, Others in the Global Reflow Soldering Oven Market:

The Global Reflow Soldering Oven Market finds extensive usage across various industries, including telecommunications, consumer electronics, automotive, and others. In the telecommunications sector, reflow soldering ovens are crucial for the assembly of complex electronic components used in communication devices and infrastructure. The demand for high-speed internet and advanced communication technologies drives the need for reliable and efficient soldering solutions, making reflow soldering ovens an essential part of the manufacturing process. In consumer electronics, these ovens play a vital role in the production of a wide range of devices, from smartphones and tablets to home appliances and wearable technology. The increasing complexity and miniaturization of electronic components in consumer devices require precise and efficient soldering techniques, which reflow soldering ovens provide. In the automotive industry, the shift towards electric and autonomous vehicles has led to a surge in demand for advanced electronic systems. Reflow soldering ovens are used to assemble critical components such as sensors, control units, and battery management systems, ensuring the reliability and performance of automotive electronics. Other industries, including aerospace, medical devices, and industrial equipment, also rely on reflow soldering ovens for the assembly of electronic components. The versatility and efficiency of these ovens make them indispensable in the production of high-quality electronic assemblies across various sectors. As technology continues to advance, the Global Reflow Soldering Oven Market is expected to grow, driven by the increasing demand for sophisticated electronic devices and the need for reliable soldering solutions.

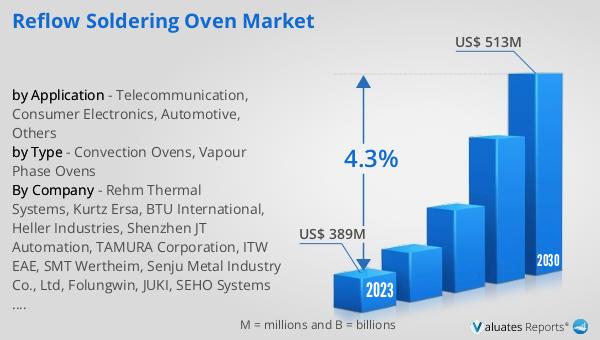

Global Reflow Soldering Oven Market Outlook:

The global market for Reflow Soldering Ovens was valued at $399 million in 2024 and is anticipated to grow to a revised size of $578 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period. The top five manufacturers dominate approximately 43% of the global market share, highlighting the competitive nature of the industry. The Asia-Pacific region stands out as the largest production hub, accounting for nearly 78% of the market share, underscoring its significance in the global electronics manufacturing landscape. Within the product segments, convection ovens emerge as the largest category, holding a market share of over 84%. This dominance is attributed to their efficiency, versatility, and ability to meet the diverse needs of manufacturers across various industries. The market's growth is driven by the increasing demand for electronic devices and the need for advanced soldering solutions to ensure the reliability and performance of electronic assemblies. As the electronics industry continues to evolve, the Global Reflow Soldering Oven Market is poised for significant expansion, driven by technological advancements and the growing complexity of electronic devices.

| Report Metric | Details |

| Report Name | Reflow Soldering Oven Market |

| Accounted market size in year | US$ 399 million |

| Forecasted market size in 2031 | US$ 578 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rehm Thermal Systems, Kurtz Ersa, BTU International, Heller Industries, Shenzhen JT Automation, TAMURA Corporation, ITW EAE, SMT Wertheim, Folungwin, Senju Metal Industry Co., Ltd, JUKI, SEHO Systems GmbH, Suneast, ETA, Papaw, EIGHTECH TECTRON, ATV Technologie GmbH, 3S Silicon, HIRATA Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |