What is Global Aerospace Grade Aluminum Honeycomb Core Market?

The Global Aerospace Grade Aluminum Honeycomb Core Market is a specialized segment within the aerospace industry that focuses on the production and application of aluminum honeycomb cores. These cores are lightweight, strong, and have excellent energy absorption properties, making them ideal for use in various aerospace applications. The honeycomb structure is inspired by the natural design of a beehive, providing a high strength-to-weight ratio that is crucial for aerospace components. This market is driven by the increasing demand for lightweight and fuel-efficient aircraft, as well as the growing use of advanced materials in aerospace engineering. The aluminum honeycomb core is used in a variety of applications, including aircraft interiors, structural components, and satellite panels, due to its ability to withstand high stress and temperature variations. The market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the performance and durability of these cores to meet the stringent requirements of the aerospace industry. As the aerospace sector continues to expand, the demand for high-quality aluminum honeycomb cores is expected to rise, making this market a key area of interest for manufacturers and investors alike.

5052 Aluminum Alloy, 5056 Aluminum Alloy in the Global Aerospace Grade Aluminum Honeycomb Core Market:

5052 and 5056 aluminum alloys are integral to the Global Aerospace Grade Aluminum Honeycomb Core Market due to their unique properties that make them suitable for aerospace applications. The 5052 aluminum alloy is known for its excellent corrosion resistance, particularly in marine environments, which is beneficial for aerospace components exposed to harsh conditions. It is also highly formable and has good weldability, making it a versatile choice for manufacturing complex shapes and structures. The alloy's high fatigue strength and moderate static strength make it ideal for use in aircraft fuel tanks, hydraulic tubes, and other components where durability and reliability are paramount. On the other hand, the 5056 aluminum alloy is prized for its superior strength and resistance to corrosion, especially in saltwater environments. This makes it an excellent choice for aerospace applications that require high strength and durability. The 5056 alloy is often used in the production of rivets and fasteners, which are critical components in aircraft construction. Its ability to maintain structural integrity under extreme conditions makes it a preferred material for aerospace engineers. Both 5052 and 5056 aluminum alloys are used in the production of honeycomb cores, where their properties contribute to the overall performance and efficiency of the final product. The choice between these two alloys depends on the specific requirements of the application, such as the need for corrosion resistance, strength, or formability. Manufacturers in the aerospace industry carefully select the appropriate alloy to ensure that the honeycomb cores meet the stringent standards and specifications required for aerospace applications. The use of these alloys in honeycomb cores not only enhances the performance of aerospace components but also contributes to the overall safety and efficiency of aircraft and spacecraft. As the aerospace industry continues to evolve, the demand for high-performance materials like 5052 and 5056 aluminum alloys is expected to grow, driving further innovation and development in the Global Aerospace Grade Aluminum Honeycomb Core Market.

Aircraft Components, Space and Satellite Components, Rocket Components, Others in the Global Aerospace Grade Aluminum Honeycomb Core Market:

The Global Aerospace Grade Aluminum Honeycomb Core Market finds extensive usage in various areas, including aircraft components, space and satellite components, rocket components, and others. In aircraft components, aluminum honeycomb cores are used in the construction of wings, fuselage panels, and control surfaces due to their lightweight and high strength properties. These cores help reduce the overall weight of the aircraft, leading to improved fuel efficiency and performance. Additionally, they provide excellent energy absorption, which enhances the safety and durability of the aircraft. In space and satellite components, aluminum honeycomb cores are used in the construction of satellite panels and other structural components. The lightweight nature of these cores is crucial for space applications, where every kilogram counts. They also offer excellent thermal insulation and resistance to extreme temperatures, making them ideal for use in the harsh environment of space. In rocket components, aluminum honeycomb cores are used in the construction of fairings, payload adapters, and other structural elements. The high strength-to-weight ratio of these cores is essential for ensuring the structural integrity of rockets during launch and flight. Additionally, their ability to withstand high stress and vibration makes them suitable for use in rocket components. Beyond these specific applications, aluminum honeycomb cores are also used in other areas such as automotive, marine, and construction industries, where their lightweight and high strength properties are valued. The versatility and performance of aluminum honeycomb cores make them a preferred choice for a wide range of applications, driving their demand in the Global Aerospace Grade Aluminum Honeycomb Core Market.

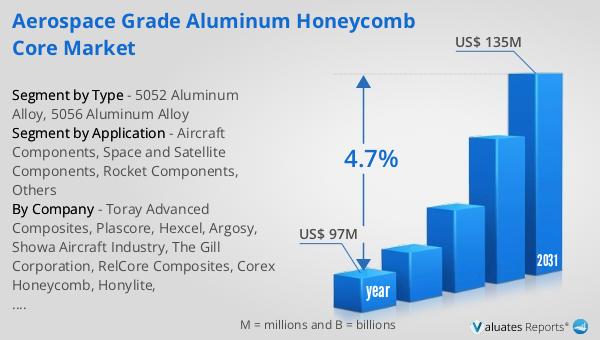

Global Aerospace Grade Aluminum Honeycomb Core Market Outlook:

The global market for Aerospace Grade Aluminum Honeycomb Core was valued at approximately $97 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $135 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.7% over the forecast period. The increasing demand for lightweight and fuel-efficient aircraft is a major driver of this market growth. As the aerospace industry continues to evolve, the need for advanced materials that offer high strength-to-weight ratios and excellent energy absorption properties is becoming increasingly important. Aluminum honeycomb cores meet these requirements, making them a key component in the construction of modern aircraft and spacecraft. The market is also driven by the growing use of aluminum honeycomb cores in space and satellite components, where their lightweight and high strength properties are crucial for ensuring the performance and reliability of these systems. Additionally, the increasing focus on sustainability and environmental impact is driving the demand for materials that can help reduce the carbon footprint of aerospace operations. Aluminum honeycomb cores, with their lightweight and recyclable nature, are well-suited to meet these demands. As a result, the Global Aerospace Grade Aluminum Honeycomb Core Market is expected to continue its growth trajectory, offering significant opportunities for manufacturers and investors in the coming years.

| Report Metric | Details |

| Report Name | Aerospace Grade Aluminum Honeycomb Core Market |

| Accounted market size in year | US$ 97 million |

| Forecasted market size in 2031 | US$ 135 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray Advanced Composites, Plascore, Hexcel, Argosy, Showa Aircraft Industry, The Gill Corporation, RelCore Composites, Corex Honeycomb, Honylite, EURO‑COMPOSITES, I.MA.TEC., Miltech International, AVIC Composite, Liming Honeycomb Composites, Suzhou Beecore Honeycomb Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |