What is Global Medium Frequency Fixed Spot Welding Machine Market?

The Global Medium Frequency Fixed Spot Welding Machine Market is a specialized segment within the broader welding equipment industry. These machines are designed to perform spot welding, a process where two or more metal sheets are joined together at specific points by applying pressure and heat. The "medium frequency" aspect refers to the electrical current used in the welding process, which operates at a frequency higher than the standard 50/60 Hz, typically around 1,000 Hz. This higher frequency allows for more precise control of the welding process, resulting in stronger and more consistent welds. These machines are fixed, meaning they are stationary and typically used in production lines where repetitive welding tasks are required. The market for these machines is driven by industries that require high-quality, reliable welding solutions, such as automotive manufacturing, aerospace, and heavy machinery production. As industries continue to demand more efficient and precise welding solutions, the market for medium frequency fixed spot welding machines is expected to grow, driven by technological advancements and the need for improved production efficiency.

Air Cooling, Water Cooling, Oil Cooling in the Global Medium Frequency Fixed Spot Welding Machine Market:

In the realm of Global Medium Frequency Fixed Spot Welding Machines, cooling methods play a crucial role in ensuring the efficiency and longevity of the equipment. Air cooling, water cooling, and oil cooling are the primary methods employed to manage the heat generated during the welding process. Air cooling is the simplest and most cost-effective method, utilizing ambient air to dissipate heat. This method is suitable for applications where the welding machine is not subjected to continuous heavy-duty use. However, air cooling may not be sufficient for high-intensity operations, as it relies heavily on the surrounding environment's temperature and airflow, which can be inconsistent. Water cooling, on the other hand, is more efficient and effective for high-performance welding machines. It involves circulating water through a closed-loop system to absorb and dissipate heat. This method provides consistent cooling, making it ideal for applications that require prolonged and intensive welding operations. Water cooling systems are often equipped with heat exchangers and pumps to maintain optimal temperature levels, ensuring the machine operates at peak efficiency. Oil cooling is another method used in medium frequency fixed spot welding machines, particularly in environments where water cooling may not be feasible. Oil has a higher boiling point than water, allowing it to absorb more heat before evaporating. This makes oil cooling suitable for extreme conditions where the machine is exposed to high temperatures for extended periods. Oil cooling systems are typically more complex and require regular maintenance to ensure the oil remains clean and effective. Each cooling method has its advantages and limitations, and the choice of cooling system depends on the specific requirements of the welding application, including the intensity of use, environmental conditions, and maintenance capabilities. Manufacturers of medium frequency fixed spot welding machines often offer customizable cooling solutions to meet the diverse needs of their clients, ensuring optimal performance and longevity of the equipment.

Automotive, Hardware, Mechanical Equipment, Others in the Global Medium Frequency Fixed Spot Welding Machine Market:

The Global Medium Frequency Fixed Spot Welding Machine Market finds extensive usage across various industries, including automotive, hardware, mechanical equipment, and others. In the automotive industry, these machines are indispensable for assembling vehicle bodies, frames, and other components. The precision and strength of the welds produced by medium frequency machines ensure the structural integrity and safety of vehicles. Automotive manufacturers rely on these machines for their ability to deliver consistent and high-quality welds, which are crucial for meeting safety standards and enhancing vehicle performance. In the hardware industry, medium frequency fixed spot welding machines are used to manufacture a wide range of products, from household appliances to industrial tools. The machines' ability to produce strong and durable welds makes them ideal for joining metal parts that require high strength and reliability. In the mechanical equipment sector, these machines are employed in the production of heavy machinery and equipment used in construction, mining, and other industries. The robust welds produced by medium frequency machines ensure the durability and longevity of mechanical components, which are often subjected to harsh operating conditions. Beyond these industries, medium frequency fixed spot welding machines are also used in various other applications, such as aerospace, electronics, and consumer goods manufacturing. In aerospace, the machines are used to join lightweight metal alloys, which are essential for reducing the weight of aircraft and improving fuel efficiency. In electronics, the machines are used to assemble components that require precise and reliable connections. The versatility and efficiency of medium frequency fixed spot welding machines make them a valuable asset in any industry that requires high-quality metal joining solutions.

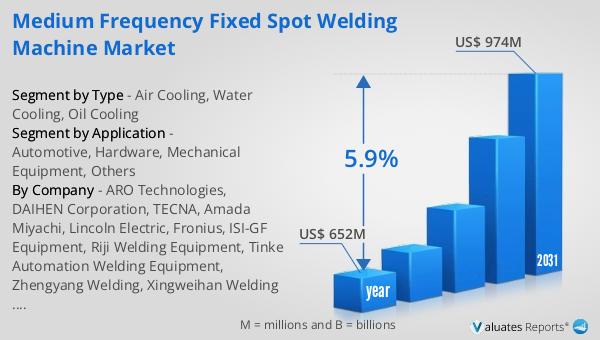

Global Medium Frequency Fixed Spot Welding Machine Market Outlook:

The global market for Medium Frequency Fixed Spot Welding Machines was valued at approximately $652 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $974 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. The increasing demand for efficient and reliable welding solutions across various industries is a key driver of this market growth. As industries such as automotive, aerospace, and heavy machinery continue to evolve, the need for advanced welding technologies that offer precision, strength, and efficiency is becoming more pronounced. Medium frequency fixed spot welding machines are well-suited to meet these demands, offering superior performance compared to traditional welding methods. The market's growth is also supported by technological advancements that enhance the capabilities of these machines, making them more versatile and user-friendly. As a result, manufacturers are increasingly investing in research and development to innovate and improve their product offerings, further fueling market expansion. The projected growth of the medium frequency fixed spot welding machine market underscores the importance of these machines in modern manufacturing processes and highlights the ongoing demand for high-quality welding solutions.

| Report Metric | Details |

| Report Name | Medium Frequency Fixed Spot Welding Machine Market |

| Accounted market size in year | US$ 652 million |

| Forecasted market size in 2031 | US$ 974 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ARO Technologies, DAIHEN Corporation, TECNA, Amada Miyachi, Lincoln Electric, Fronius, ISI-GF Equipment, Riji Welding Equipment, Tinke Automation Welding Equipment, Zhengyang Welding, Xingweihan Welding Equipment, HERON Intelligent Equipment, Haojing Electromechanical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |