What is Global Carbide Cutting Blades Market?

The Global Carbide Cutting Blades Market is a significant segment within the industrial tools industry, characterized by its specialized use in cutting and shaping hard materials. These blades are crafted from carbide, a compound composed of carbon and a less electronegative element, often tungsten. This composition gives the blades exceptional hardness and durability, making them ideal for high-speed cutting applications. The market for these blades is driven by their widespread use across various industries, including automotive, aerospace, electronics, and medical equipment manufacturing. As industries continue to demand precision and efficiency, the need for high-quality cutting tools like carbide blades increases. These blades are known for their ability to maintain sharpness over extended periods, reducing the need for frequent replacements and thus offering cost-effectiveness in long-term operations. The global market is also influenced by technological advancements that enhance the performance and lifespan of these blades, as well as by the growing trend towards automation in manufacturing processes. As a result, the Global Carbide Cutting Blades Market is poised for continued growth, driven by innovation and the expanding needs of industrial sectors worldwide.

Tungsten-cobalt Type, Titanium-tungsten-cobalt Type, Tantalum-tungsten-cobalt Type, Cobalt-based Cemented Carbide, Others in the Global Carbide Cutting Blades Market:

The Global Carbide Cutting Blades Market is diverse, with several types of carbide compositions catering to different industrial needs. The Tungsten-cobalt type is one of the most common, known for its excellent toughness and resistance to wear. This type is particularly suitable for applications requiring high impact resistance, such as in heavy-duty cutting tasks. The presence of cobalt enhances the blade's ability to withstand thermal and mechanical stress, making it a preferred choice in industries where durability is paramount. On the other hand, the Titanium-tungsten-cobalt type offers a unique combination of hardness and toughness. The addition of titanium improves the blade's resistance to oxidation and corrosion, which is crucial in environments exposed to harsh chemicals or extreme temperatures. This type is often used in precision cutting tasks where maintaining edge sharpness is critical. The Tantalum-tungsten-cobalt type is another variant, known for its superior hardness and thermal stability. Tantalum's inclusion provides enhanced resistance to heat and wear, making these blades ideal for high-speed cutting operations. This type is often employed in industries where precision and speed are essential, such as in aerospace and electronics manufacturing. Cobalt-based cemented carbide is a versatile type that combines cobalt with other carbides to achieve a balance of hardness and toughness. This type is widely used in general-purpose cutting applications, offering a cost-effective solution without compromising on performance. It is particularly popular in the automotive industry, where a variety of materials need to be cut with precision and efficiency. Lastly, there are other specialized carbide compositions designed for niche applications. These may include blends with additional elements to enhance specific properties, such as increased resistance to specific types of wear or improved performance in unique environmental conditions. The diversity in carbide compositions allows manufacturers to select the most appropriate type for their specific needs, ensuring optimal performance and longevity of the cutting blades. As industries continue to evolve and demand more specialized tools, the variety within the Global Carbide Cutting Blades Market is expected to expand, offering even more tailored solutions for diverse industrial applications.

Automobile Manufacturing, Aerospace, Medical Equipment, Electronics Industry, Others in the Global Carbide Cutting Blades Market:

The Global Carbide Cutting Blades Market finds extensive usage across various industries, each with its unique requirements and challenges. In the automobile manufacturing sector, these blades are indispensable for cutting and shaping metal components with precision. The ability to maintain sharpness and withstand high-speed operations makes carbide blades ideal for producing intricate parts that require exact specifications. This precision is crucial in ensuring the safety and performance of vehicles, as even minor deviations can lead to significant issues. In the aerospace industry, the demand for carbide cutting blades is driven by the need for high-performance materials that can withstand extreme conditions. These blades are used to cut and shape components made from advanced alloys and composites, which are essential for building lightweight and durable aircraft. The aerospace sector's stringent quality standards necessitate the use of cutting tools that can deliver consistent and precise results, making carbide blades a preferred choice. The medical equipment industry also relies heavily on carbide cutting blades for manufacturing surgical instruments and other medical devices. The blades' ability to produce clean and precise cuts is vital in ensuring the functionality and safety of medical tools. Additionally, the resistance to wear and corrosion offered by carbide blades is crucial in maintaining the sterility and longevity of medical equipment. In the electronics industry, carbide cutting blades are used to cut and shape components made from various materials, including metals, plastics, and ceramics. The precision and durability of these blades are essential in producing electronic components that meet the industry's high standards for performance and reliability. As electronic devices become more complex and miniaturized, the demand for precise cutting tools like carbide blades continues to grow. Beyond these industries, carbide cutting blades are also used in other sectors such as construction, woodworking, and metalworking. Their versatility and durability make them suitable for a wide range of applications, from cutting through tough materials like concrete and steel to shaping delicate wood and plastic components. The ability to deliver precise and efficient cuts across diverse materials and industries underscores the importance of carbide cutting blades in modern manufacturing processes. As industries continue to innovate and seek more efficient production methods, the role of carbide cutting blades in facilitating these advancements remains critical.

Global Carbide Cutting Blades Market Outlook:

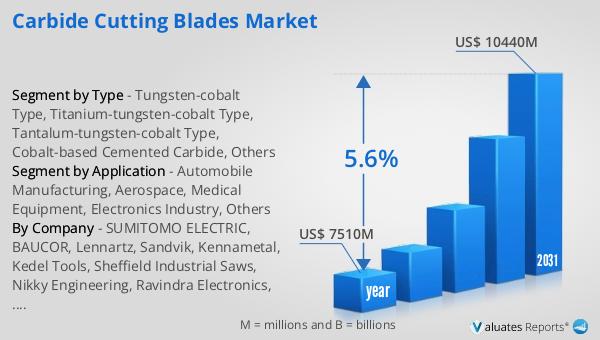

In 2024, the global market for Carbide Cutting Blades was valued at approximately $7.51 billion. Looking ahead, this market is anticipated to expand significantly, reaching an estimated value of $10.44 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.6% over the forecast period. The steady increase in market size reflects the rising demand for high-performance cutting tools across various industries. As manufacturing processes become more sophisticated and the need for precision and efficiency intensifies, the adoption of carbide cutting blades is expected to rise. These blades offer superior durability and cutting performance, making them indispensable in sectors such as automotive, aerospace, electronics, and medical equipment manufacturing. The projected growth also underscores the impact of technological advancements in enhancing the quality and lifespan of carbide blades. As industries continue to evolve and require more specialized tools, the market for carbide cutting blades is poised to expand, driven by innovation and the increasing complexity of industrial applications. This positive market outlook highlights the critical role that carbide cutting blades play in modern manufacturing, supporting the production of high-quality components and products across diverse sectors.

| Report Metric | Details |

| Report Name | Carbide Cutting Blades Market |

| Accounted market size in year | US$ 7510 million |

| Forecasted market size in 2031 | US$ 10440 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | SUMITOMO ELECTRIC, BAUCOR, Lennartz, Sandvik, Kennametal, Kedel Tools, Sheffield Industrial Saws, Nikky Engineering, Ravindra Electronics, ONMY Tools, Zhuzhou Better Tungsten Carbide Co.,Ltd, Smit Engineering, Hangzhou Wagen Precision Tooling Co.,Ltd, VASTTA, Hyperion Materials & Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |