What is Global High-Temperature Short-Time (HTST) Pasteurization Systems Market?

The Global High-Temperature Short-Time (HTST) Pasteurization Systems Market is a specialized segment within the broader food processing industry, focusing on the pasteurization of liquid products. HTST pasteurization is a method that involves heating a product to a specific temperature for a short period to kill harmful microorganisms, ensuring the product's safety and extending its shelf life. This process is particularly significant in industries like dairy, beverages, and prepared foods, where maintaining product quality and safety is paramount. The market for HTST pasteurization systems is driven by the increasing demand for safe and high-quality food products, coupled with stringent food safety regulations worldwide. As consumers become more health-conscious, the need for efficient pasteurization methods that preserve nutritional value while ensuring safety has grown. HTST systems are favored for their ability to process large volumes quickly, making them ideal for large-scale production facilities. The market is characterized by technological advancements aimed at improving efficiency and reducing energy consumption, reflecting a broader trend towards sustainability in food processing. Overall, the Global HTST Pasteurization Systems Market plays a crucial role in ensuring food safety and quality, meeting the demands of both consumers and regulatory bodies.

600L/h, 1200L/h, 2000L/h, 3000L/h in the Global High-Temperature Short-Time (HTST) Pasteurization Systems Market:

In the Global High-Temperature Short-Time (HTST) Pasteurization Systems Market, systems are often categorized by their processing capacity, measured in liters per hour (L/h). The capacities of 600L/h, 1200L/h, 2000L/h, and 3000L/h represent different scales of operation, catering to various production needs. A 600L/h system is typically suited for small to medium-sized operations, such as artisanal producers or niche markets, where the focus is on quality and customization rather than volume. These systems are compact, energy-efficient, and offer flexibility, making them ideal for businesses that prioritize product differentiation and innovation. The 1200L/h systems cater to medium-sized enterprises that require a balance between production volume and operational efficiency. These systems are often used by companies that are expanding their market reach and need to increase production capacity without compromising on quality. They offer a good balance of speed and efficiency, allowing businesses to scale up operations smoothly. The 2000L/h systems are designed for larger operations, where the emphasis is on high-volume production. These systems are robust, capable of handling continuous production cycles, and are often used by established companies with a wide distribution network. They are engineered to maximize throughput while maintaining stringent quality standards, making them a preferred choice for large-scale manufacturers. Finally, the 3000L/h systems represent the pinnacle of HTST pasteurization technology, designed for the largest operations with the highest production demands. These systems are equipped with advanced features for optimal performance, including automated controls, energy recovery systems, and real-time monitoring capabilities. They are used by multinational corporations and large processing plants that require consistent, high-quality output to meet global demand. Each capacity level within the HTST pasteurization systems market addresses specific operational needs, allowing businesses to choose systems that align with their production goals and market strategies. The diversity in system capacities reflects the market's adaptability to different scales of operation, ensuring that businesses of all sizes can benefit from the efficiency and safety offered by HTST pasteurization.

Dairy Products, Prepared Foods, Beverages, Others in the Global High-Temperature Short-Time (HTST) Pasteurization Systems Market:

The usage of Global High-Temperature Short-Time (HTST) Pasteurization Systems spans several key areas, including dairy products, prepared foods, beverages, and others, each with unique requirements and benefits. In the dairy industry, HTST pasteurization is crucial for ensuring the safety and quality of products like milk, cheese, and yogurt. The process effectively eliminates harmful bacteria while preserving essential nutrients and flavors, making it a preferred method for dairy producers worldwide. HTST systems allow for the rapid processing of large volumes, which is essential for meeting the high demand for dairy products. In prepared foods, HTST pasteurization is used to enhance the safety and shelf life of products such as soups, sauces, and ready-to-eat meals. The process ensures that these products are free from pathogens, providing consumers with safe and convenient meal options. The ability to maintain product quality and taste is a significant advantage, as it allows manufacturers to offer high-quality prepared foods that meet consumer expectations. In the beverage industry, HTST pasteurization is applied to products like juices, teas, and non-dairy milk alternatives. The process ensures that beverages are safe for consumption while retaining their natural flavors and nutritional content. This is particularly important in a market where consumers are increasingly seeking healthy and natural beverage options. HTST systems enable beverage producers to meet these demands efficiently, supporting the growth of the industry. Beyond these primary areas, HTST pasteurization is also used in other sectors, such as egg processing and plant-based products. In egg processing, HTST systems ensure that liquid eggs are safe for consumption, reducing the risk of foodborne illnesses. For plant-based products, HTST pasteurization helps maintain the quality and safety of items like plant-based milks and protein drinks, catering to the growing demand for vegan and vegetarian options. Overall, the versatility and efficiency of HTST pasteurization systems make them an invaluable tool across various industries, supporting the production of safe, high-quality food and beverage products.

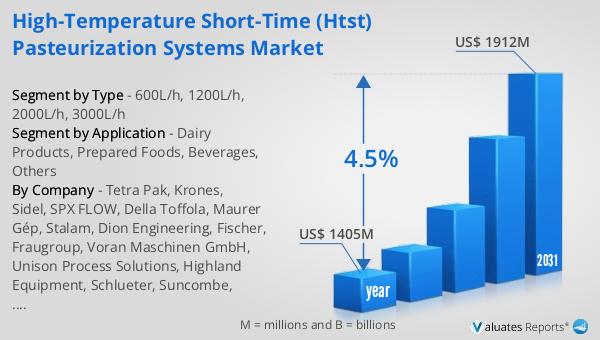

Global High-Temperature Short-Time (HTST) Pasteurization Systems Market Outlook:

The global market for High-Temperature Short-Time (HTST) Pasteurization Systems was valued at $1,405 million in 2024 and is anticipated to grow to a revised size of $1,912 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable pasteurization solutions across various industries. As food safety regulations become more stringent and consumer awareness about foodborne illnesses rises, the adoption of HTST pasteurization systems is expected to expand. These systems offer a compelling combination of speed, efficiency, and safety, making them an attractive option for manufacturers looking to enhance their production capabilities. The projected growth in the market size also highlights the ongoing technological advancements in HTST systems, which are continually being refined to improve performance and energy efficiency. As the market evolves, manufacturers are likely to focus on developing systems that cater to the specific needs of different industries, ensuring that they can meet the diverse demands of their customers. The steady growth of the HTST pasteurization systems market reflects its critical role in the global food processing industry, providing essential solutions for ensuring product safety and quality.

| Report Metric | Details |

| Report Name | High-Temperature Short-Time (HTST) Pasteurization Systems Market |

| Accounted market size in year | US$ 1405 million |

| Forecasted market size in 2031 | US$ 1912 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tetra Pak, Krones, Sidel, SPX FLOW, Della Toffola, Maurer Gép, Stalam, Dion Engineering, Fischer, Fraugroup, Voran Maschinen GmbH, Unison Process Solutions, Highland Equipment, Schlueter, Suncombe, Teknoice Srl |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |