What is Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market?

Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) is a chemical compound that plays a crucial role in various industrial applications. It is primarily used as a monomer in the production of polysulfone polymers, which are known for their high thermal stability, mechanical strength, and chemical resistance. These properties make DCDPS an essential component in industries that require durable and reliable materials. The global market for DCDPS is driven by its demand in sectors such as electronics, automotive, and medical devices, where high-performance materials are critical. The compound's ability to withstand harsh environments and maintain its integrity under stress makes it invaluable in these applications. Additionally, the growing emphasis on sustainability and the need for materials that can endure extreme conditions without degrading further fuel the demand for DCDPS. As industries continue to innovate and seek materials that offer both performance and longevity, the importance of DCDPS in the global market is expected to grow, making it a key player in the advancement of modern technology and industrial processes.

Industrial Grade, Pharma Grade, Reagent Grade in the Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market:

In the Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market, the compound is available in various grades, each tailored to specific applications and industry requirements. Industrial Grade DCDPS is primarily used in the manufacturing of high-performance polymers such as polysulfones and polyethersulfones. These polymers are utilized in industries that demand materials with exceptional thermal and chemical resistance, such as aerospace, automotive, and electronics. The Industrial Grade is characterized by its ability to withstand high temperatures and corrosive environments, making it ideal for applications where durability and reliability are paramount. On the other hand, Pharma Grade DCDPS is used in the pharmaceutical industry, where purity and safety are of utmost importance. This grade is employed in the synthesis of active pharmaceutical ingredients (APIs) and intermediates, ensuring that the final products meet stringent regulatory standards. The Pharma Grade is meticulously processed to eliminate impurities, ensuring that it does not interfere with the efficacy or safety of pharmaceutical products. Reagent Grade DCDPS is used in research and development settings, where precision and accuracy are critical. This grade is often utilized in laboratories for chemical synthesis and analysis, providing researchers with a reliable and consistent compound for their experiments. The Reagent Grade is characterized by its high purity and consistency, making it an essential tool for scientists and researchers working on cutting-edge projects. Each grade of DCDPS serves a unique purpose, catering to the diverse needs of various industries and ensuring that the compound can be effectively utilized in a wide range of applications. The availability of different grades allows manufacturers and researchers to select the most appropriate form of DCDPS for their specific requirements, optimizing performance and ensuring the success of their projects. As the demand for high-performance materials continues to grow, the significance of DCDPS in the global market is expected to increase, further highlighting the importance of its various grades in meeting the evolving needs of industries worldwide.

Electronics and Consumer Goods, Medical Devices, Automotive, Other in the Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market:

The Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market finds extensive usage across several key sectors, including electronics and consumer goods, medical devices, automotive, and others. In the electronics and consumer goods industry, DCDPS is a vital component in the production of high-performance polymers used in the manufacturing of electronic components and devices. These polymers offer excellent thermal stability and electrical insulation properties, making them ideal for use in electronic housings, connectors, and circuit boards. The demand for durable and reliable electronic products drives the need for materials like DCDPS, which can withstand the rigors of daily use and harsh environmental conditions. In the medical devices sector, DCDPS is used to produce materials that require high levels of biocompatibility and sterilization resistance. Medical devices such as surgical instruments, diagnostic equipment, and implantable devices benefit from the chemical resistance and durability provided by DCDPS-based polymers. These materials ensure that medical devices can be safely used in clinical settings without compromising patient safety or device performance. The automotive industry also relies on DCDPS for the production of components that require high thermal and chemical resistance. Polymers derived from DCDPS are used in the manufacturing of under-the-hood components, fuel system parts, and interior components, where they provide the necessary strength and durability to withstand the demanding conditions of automotive environments. Additionally, DCDPS is used in other industries such as aerospace, where its high-performance properties are essential for the production of lightweight and durable components. The versatility and reliability of DCDPS make it a valuable material in various applications, driving its demand across multiple sectors. As industries continue to innovate and seek materials that offer both performance and longevity, the usage of DCDPS in the global market is expected to expand, further solidifying its role as a key player in the advancement of modern technology and industrial processes.

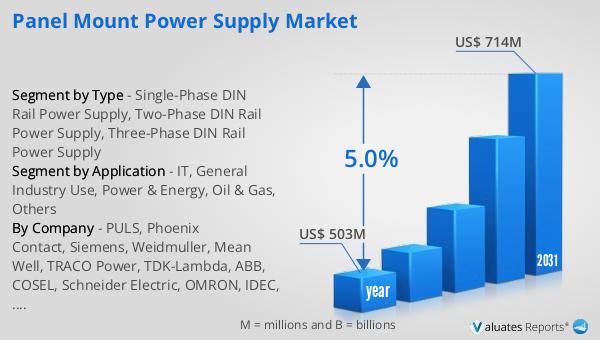

Global 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market Outlook:

The global market for 4,4-Dichlorodiphenyl Sulfone (DCDPS) was valued at approximately $427 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $640 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. The increasing demand for high-performance materials across various industries is a major factor contributing to this growth. As sectors such as electronics, automotive, and medical devices continue to expand and innovate, the need for materials that offer exceptional thermal stability, chemical resistance, and mechanical strength becomes more pronounced. DCDPS, with its unique properties, is well-positioned to meet these demands, driving its market growth. The projected increase in market size reflects the growing recognition of DCDPS as a critical component in the development of advanced materials and technologies. As industries strive to enhance the performance and durability of their products, the role of DCDPS in the global market is expected to become increasingly significant, underscoring its importance in the future of industrial and technological advancements.

| Report Metric | Details |

| Report Name | 4,4-Dichlorodiphenyl Sulfone (DCDPS) Market |

| Accounted market size in year | US$ 427 million |

| Forecasted market size in 2031 | US$ 640 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Solvay S.A., Atul Ltd., Toray Industries, Inc., Sigma-Aldrich (Merck KGaA), Vertellus Holdings LLC, Tokyo Chemical Industry Co., Ltd. (TCI), Thermo Fisher Scientific Inc., Santa Cruz Biotechnology, Inc., Connect Chemical GmbH, Shree Ganesh Chemicals, Deepak Nitrite Ltd., Hangzhou Keying Chem Co., Ltd., Capot Chemical Co., Ltd., Synasia Inc., Henan Tianfu Chemical Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |