What is Global Inline Print Inspection System Market?

The Global Inline Print Inspection System Market refers to the industry focused on technologies that ensure the quality and accuracy of printed materials during the production process. These systems are integrated into printing lines to monitor and inspect printed materials in real-time, identifying defects such as color variations, misprints, and other inconsistencies. By doing so, they help maintain high-quality standards and reduce waste, as errors can be detected and corrected immediately. This market is driven by the increasing demand for high-quality printed materials across various industries, including packaging, publishing, and labeling. As businesses strive to enhance their brand image and meet regulatory standards, the adoption of inline print inspection systems becomes crucial. These systems not only improve operational efficiency but also contribute to cost savings by minimizing rework and material wastage. With advancements in technology, these systems are becoming more sophisticated, offering features like high-resolution imaging, automated defect detection, and data analytics, which further enhance their effectiveness and appeal to a broader range of industries.

Sheet Inspection System, Web Inspection System in the Global Inline Print Inspection System Market:

The Global Inline Print Inspection System Market encompasses various technologies, among which Sheet Inspection Systems and Web Inspection Systems are prominent. Sheet Inspection Systems are designed to inspect individual sheets of printed material. These systems are particularly useful in industries where high precision is required, such as in the production of currency, high-security documents, and high-quality packaging. They work by scanning each sheet for defects, ensuring that every piece meets the required quality standards before it moves to the next stage of production. This meticulous inspection process helps in maintaining consistency and quality, which is crucial for industries where even minor defects can lead to significant financial losses or security breaches. On the other hand, Web Inspection Systems are used for continuous materials, such as rolls of paper, film, or foil. These systems are essential in industries like packaging, textiles, and printing, where materials are produced in large volumes and at high speeds. Web Inspection Systems are equipped with advanced sensors and cameras that continuously monitor the material as it moves through the production line. They can detect a wide range of defects, including color variations, misalignments, and surface imperfections. By providing real-time feedback, these systems enable manufacturers to make immediate adjustments, thereby reducing waste and improving overall efficiency. Both Sheet and Web Inspection Systems are integral to the Global Inline Print Inspection System Market, as they cater to different needs and applications across various industries. The choice between the two depends on the specific requirements of the production process, such as the type of material being printed, the speed of production, and the level of precision required. As technology continues to evolve, these systems are becoming more sophisticated, offering enhanced capabilities such as machine learning algorithms for defect detection, integration with other production systems for seamless operations, and advanced data analytics for better decision-making. This evolution is driving the growth of the Global Inline Print Inspection System Market, as more industries recognize the value of investing in these technologies to ensure quality, efficiency, and competitiveness.

Food and Beverages, Pharmaceuticals, Consumer Products, Others in the Global Inline Print Inspection System Market:

The Global Inline Print Inspection System Market finds extensive usage across various sectors, including Food and Beverages, Pharmaceuticals, Consumer Products, and others. In the Food and Beverages industry, these systems play a crucial role in ensuring that packaging meets stringent quality and safety standards. With increasing consumer awareness and regulatory requirements, manufacturers are under pressure to deliver products that are not only safe but also visually appealing. Inline print inspection systems help achieve this by detecting defects in labels and packaging, such as incorrect information, color variations, or misprints, which could otherwise lead to costly recalls or damage to brand reputation. In the Pharmaceuticals sector, the importance of inline print inspection systems cannot be overstated. Given the critical nature of pharmaceutical products, any error in packaging or labeling can have serious consequences. These systems ensure that all printed materials, including labels, cartons, and inserts, are free from defects and accurately convey the necessary information. This is vital for compliance with regulatory standards and for maintaining patient safety. In the Consumer Products industry, where brand image and customer satisfaction are paramount, inline print inspection systems help maintain high-quality standards by ensuring that packaging and labels are flawless. This is particularly important in a competitive market where consumers have numerous choices, and even a minor defect can influence purchasing decisions. Other industries, such as electronics, automotive, and textiles, also benefit from the use of inline print inspection systems. In these sectors, the focus is on ensuring that printed materials, whether they are labels, instructions, or decorative elements, meet the required quality standards. By integrating these systems into their production lines, manufacturers can enhance their operational efficiency, reduce waste, and improve product quality. Overall, the Global Inline Print Inspection System Market is instrumental in helping various industries meet their quality and regulatory requirements, thereby enhancing their competitiveness and customer satisfaction.

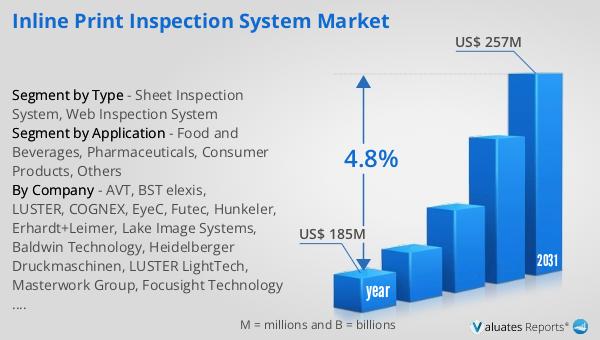

Global Inline Print Inspection System Market Outlook:

The global market for Inline Print Inspection Systems was valued at $185 million in 2024 and is anticipated to grow to a revised size of $257 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.8% over the forecast period. This growth trajectory underscores the increasing demand for quality assurance in printed materials across diverse industries. As businesses continue to prioritize quality and efficiency, the adoption of inline print inspection systems is expected to rise. These systems offer significant advantages, such as real-time defect detection, reduced waste, and improved operational efficiency, which are critical in today's competitive market environment. The projected growth in this market is also driven by technological advancements that enhance the capabilities of these systems, making them more effective and user-friendly. As industries such as packaging, pharmaceuticals, and consumer goods continue to expand, the need for reliable and efficient print inspection solutions becomes even more pronounced. This market outlook highlights the importance of inline print inspection systems in ensuring product quality and compliance with industry standards, ultimately contributing to the overall growth and success of businesses across various sectors.

| Report Metric | Details |

| Report Name | Inline Print Inspection System Market |

| Accounted market size in year | US$ 185 million |

| Forecasted market size in 2031 | US$ 257 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AVT, BST elexis, LUSTER, COGNEX, EyeC, Futec, Hunkeler, Erhardt+Leimer, Lake Image Systems, Baldwin Technology, Heidelberger Druckmaschinen, LUSTER LightTech, Masterwork Group, Focusight Technology (Jiang Su), Procemex, Beijing Daheng Image Vision, Beijing Sino-Mv Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |