What is Global Laser Micro-Welding Systems Market?

The Global Laser Micro-Welding Systems Market is a specialized segment within the broader welding industry, focusing on the precision joining of small components using laser technology. This market is driven by the increasing demand for miniaturized components across various industries, including electronics, medical devices, and aerospace. Laser micro-welding systems offer high precision, minimal thermal distortion, and the ability to weld complex geometries, making them ideal for applications where traditional welding methods fall short. These systems utilize a concentrated laser beam to melt and fuse materials at a microscopic level, ensuring strong and reliable joints. The market is characterized by continuous technological advancements, with manufacturers striving to enhance the efficiency, accuracy, and versatility of these systems. As industries continue to push the boundaries of miniaturization and precision, the demand for laser micro-welding systems is expected to grow, driven by their ability to meet the stringent requirements of modern manufacturing processes. The market's growth is also supported by the increasing adoption of automation and the need for high-quality, defect-free products in competitive global markets. Overall, the Global Laser Micro-Welding Systems Market plays a crucial role in enabling the production of advanced, high-performance products across various sectors.

Low Power (<100W), Medium Power (100W-500W), High Power (>500W) in the Global Laser Micro-Welding Systems Market:

In the Global Laser Micro-Welding Systems Market, power levels are a critical factor that determines the system's capabilities and applications. These systems are typically categorized into three power levels: Low Power (<100W), Medium Power (100W-500W), and High Power (>500W). Each category serves distinct purposes and is suited for different industrial needs. Low Power laser micro-welding systems, with power outputs of less than 100 watts, are primarily used for applications requiring extreme precision and minimal heat input. These systems are ideal for delicate tasks such as welding thin wires, small electronic components, and intricate medical devices. The low power ensures that the surrounding material is not damaged, maintaining the integrity of the components being welded. Medium Power systems, ranging from 100 to 500 watts, offer a balance between precision and power. They are versatile and can handle a wider range of materials and thicknesses compared to low power systems. Medium power systems are commonly used in the electronics industry for tasks such as battery tab welding and in the medical field for assembling surgical instruments. These systems provide sufficient power to create strong welds while still maintaining a high level of precision. High Power laser micro-welding systems, with outputs exceeding 500 watts, are designed for heavy-duty applications where strength and penetration depth are crucial. These systems are used in industries such as aerospace and automotive, where robust welds are necessary to withstand extreme conditions. High power systems can weld thicker materials and are capable of joining dissimilar metals, making them suitable for complex assemblies. Despite their higher power, these systems still offer the precision and control needed for micro-welding applications. The choice of power level in laser micro-welding systems depends on the specific requirements of the application, including the materials being welded, the desired weld strength, and the level of precision needed. Manufacturers often offer customizable solutions to meet the diverse needs of their clients, ensuring that the chosen system aligns with the intended use. As technology advances, the capabilities of each power category continue to expand, offering improved performance and efficiency. The Global Laser Micro-Welding Systems Market is thus characterized by a wide range of options, allowing industries to select the most appropriate system for their specific applications. This flexibility is a key factor driving the adoption of laser micro-welding technology across various sectors, as it enables manufacturers to achieve high-quality results while optimizing their production processes.

Electronics Industry, Medical Equipment, Aerospace, Others in the Global Laser Micro-Welding Systems Market:

The Global Laser Micro-Welding Systems Market finds extensive usage across several key industries, each benefiting from the precision and efficiency that laser micro-welding technology offers. In the electronics industry, laser micro-welding systems are indispensable for the assembly of small and delicate components. They are used to weld tiny wires, connectors, and circuit boards, ensuring reliable electrical connections without damaging sensitive parts. The precision of laser micro-welding allows for the miniaturization of electronic devices, meeting the growing demand for compact and high-performance gadgets. In the medical equipment sector, laser micro-welding is crucial for manufacturing intricate devices such as surgical instruments, implants, and diagnostic tools. The technology ensures that these devices meet stringent quality and safety standards, providing strong and clean welds that are essential for medical applications. The ability to weld biocompatible materials without compromising their properties is a significant advantage, enabling the production of advanced medical devices that improve patient outcomes. The aerospace industry also relies heavily on laser micro-welding systems for the fabrication of critical components. The technology is used to join lightweight materials and complex assemblies, contributing to the production of efficient and reliable aircraft. Laser micro-welding ensures that aerospace components can withstand extreme conditions, such as high temperatures and pressures, enhancing the safety and performance of aircraft. Additionally, the precision of laser micro-welding allows for the creation of intricate designs that are essential for modern aerospace engineering. Beyond these industries, laser micro-welding systems are used in various other sectors, including automotive, telecommunications, and jewelry manufacturing. In the automotive industry, they are employed for tasks such as battery welding and sensor assembly, supporting the production of electric vehicles and advanced driver-assistance systems. In telecommunications, laser micro-welding is used to assemble fiber optic components, ensuring high-speed data transmission. The jewelry industry benefits from the technology's ability to create intricate designs and repair delicate pieces without visible seams. Overall, the versatility and precision of laser micro-welding systems make them a valuable tool across multiple industries, driving innovation and enhancing product quality.

Global Laser Micro-Welding Systems Market Outlook:

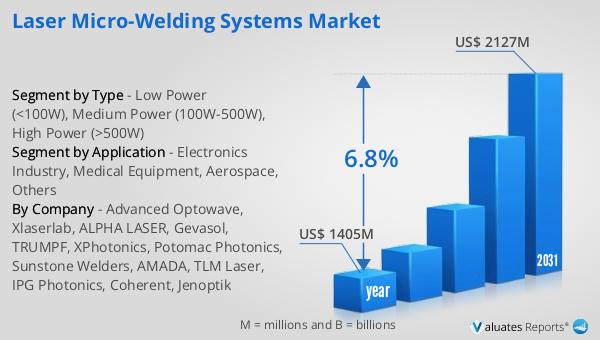

The global market for Laser Micro-Welding Systems is on a promising growth trajectory. In 2024, the market was valued at approximately $1,405 million. By 2031, it is anticipated to expand significantly, reaching an estimated value of $2,127 million. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. This upward trend is indicative of the increasing demand for precision welding solutions across various industries. The market's expansion is driven by the need for advanced manufacturing technologies that can meet the stringent requirements of modern production processes. As industries continue to innovate and push the boundaries of what is possible, the demand for laser micro-welding systems is expected to rise. These systems offer unparalleled precision and efficiency, making them an essential tool for manufacturers looking to produce high-quality, defect-free products. The projected growth of the market reflects the ongoing advancements in laser technology and the increasing adoption of automation in manufacturing. As more industries recognize the benefits of laser micro-welding, the market is poised for continued expansion, offering opportunities for manufacturers and suppliers to capitalize on this growing demand.

| Report Metric | Details |

| Report Name | Laser Micro-Welding Systems Market |

| Accounted market size in year | US$ 1405 million |

| Forecasted market size in 2031 | US$ 2127 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Advanced Optowave, Xlaserlab, ALPHA LASER, Gevasol, TRUMPF, XPhotonics, Potomac Photonics, Sunstone Welders, AMADA, TLM Laser, IPG Photonics, Coherent, Jenoptik |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |