What is Global Nitrogen Trifluoride (NF3) Market?

The Global Nitrogen Trifluoride (NF3) Market is a significant segment within the chemical industry, primarily driven by its extensive use in the electronics sector. NF3 is a colorless, non-flammable gas that is widely used as a cleaning and etching agent in the manufacturing of semiconductors, flat panel displays, and solar cells. Its unique properties make it an ideal choice for these applications, as it can effectively remove unwanted materials without damaging the delicate components of electronic devices. The demand for NF3 has been steadily increasing due to the rapid growth of the electronics industry, particularly in the Asia-Pacific region, which is a major hub for semiconductor and display manufacturing. As technology continues to advance and the demand for electronic devices grows, the NF3 market is expected to expand further, driven by innovations in manufacturing processes and the development of new applications for this versatile gas.

Chemical Synthesis, Electrolyzing Synthesis in the Global Nitrogen Trifluoride (NF3) Market:

Chemical synthesis and electrolyzing synthesis are two primary methods used in the production of Nitrogen Trifluoride (NF3), each with its own set of advantages and challenges. Chemical synthesis involves the reaction of ammonia (NH3) with fluorine (F2) under controlled conditions. This method is widely used due to its relatively straightforward process and the availability of raw materials. The reaction typically takes place in a reactor where ammonia is introduced to fluorine gas, resulting in the formation of NF3 along with some by-products such as hydrogen fluoride (HF). The process requires careful handling of fluorine, which is highly reactive and can pose safety risks if not managed properly. Despite these challenges, chemical synthesis remains a popular choice for NF3 production due to its efficiency and cost-effectiveness. On the other hand, electrolyzing synthesis is an alternative method that involves the electrolysis of a fluoride salt solution to produce NF3. This process is considered more environmentally friendly compared to chemical synthesis, as it generates fewer by-products and reduces the need for hazardous chemicals. In electrolyzing synthesis, a fluoride salt, such as ammonium fluoride (NH4F), is dissolved in a solvent and subjected to an electric current. The electrolysis process leads to the formation of NF3 gas, which is then collected and purified for use in various applications. One of the main advantages of this method is its ability to produce high-purity NF3, which is essential for applications in the electronics industry where even trace impurities can affect the performance of semiconductor devices. However, electrolyzing synthesis also presents certain challenges, particularly in terms of energy consumption and equipment costs. The process requires specialized equipment to handle the electrolysis and ensure the safe collection of NF3 gas. Additionally, the energy requirements for electrolysis can be significant, which may impact the overall cost-effectiveness of this method compared to chemical synthesis. Despite these challenges, the growing emphasis on sustainability and environmental responsibility in the chemical industry has led to increased interest in electrolyzing synthesis as a viable alternative for NF3 production. Both chemical synthesis and electrolyzing synthesis play crucial roles in meeting the global demand for NF3, particularly in the electronics sector. As the market continues to grow, manufacturers are exploring ways to optimize these production methods, improve efficiency, and reduce environmental impact. Innovations in catalyst development, process optimization, and waste management are some of the areas where ongoing research and development efforts are focused. By enhancing the production processes for NF3, manufacturers can better meet the needs of the electronics industry while minimizing the environmental footprint of their operations.

Semiconductor Chips, Flat Panel Display, Solar Cells in the Global Nitrogen Trifluoride (NF3) Market:

The usage of Nitrogen Trifluoride (NF3) in the semiconductor chips, flat panel display, and solar cell industries highlights its critical role in modern technology manufacturing. In the semiconductor industry, NF3 is primarily used as a cleaning agent for chemical vapor deposition (CVD) chambers. These chambers are essential for the production of semiconductor chips, as they allow for the precise deposition of thin films on silicon wafers. Over time, residues and unwanted materials can accumulate in the CVD chambers, affecting the quality and performance of the chips. NF3 is introduced into the chamber, where it reacts with the residues, effectively removing them without damaging the delicate components of the semiconductor devices. This cleaning process is crucial for maintaining the efficiency and reliability of semiconductor manufacturing, ensuring that the chips meet the high standards required for modern electronic devices. In the flat panel display industry, NF3 is used in a similar capacity as a cleaning and etching agent. Flat panel displays, such as those used in televisions, computer monitors, and smartphones, require precise manufacturing processes to ensure high-quality images and performance. NF3 is used to clean the deposition chambers and remove unwanted materials from the display panels, ensuring that the final product is free from defects and performs optimally. The use of NF3 in this industry is driven by the increasing demand for high-resolution displays and the rapid advancement of display technologies, which require more sophisticated manufacturing processes. The solar cell industry also benefits from the use of NF3, particularly in the production of thin-film solar cells. These cells are made by depositing thin layers of photovoltaic material onto a substrate, a process that requires precise control and cleanliness to achieve high efficiency and performance. NF3 is used to clean the deposition equipment and remove any residues that may affect the quality of the solar cells. By ensuring that the manufacturing environment is free from contaminants, NF3 helps improve the efficiency and longevity of solar cells, contributing to the overall growth of the solar energy market. The versatility and effectiveness of NF3 in these industries underscore its importance as a critical component in the manufacturing of modern electronic devices. As technology continues to evolve and the demand for advanced electronic products increases, the role of NF3 in these industries is expected to grow. Manufacturers are continually seeking ways to optimize the use of NF3, improve its efficiency, and reduce its environmental impact, ensuring that it remains a vital part of the electronics manufacturing landscape.

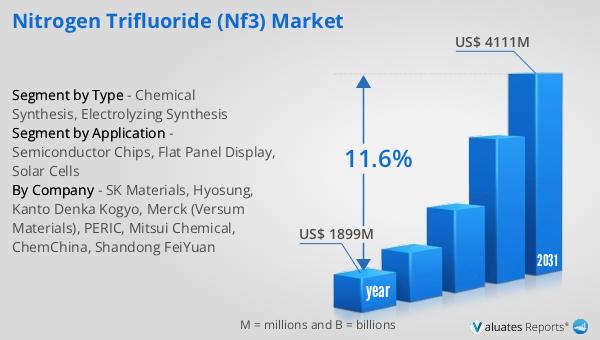

Global Nitrogen Trifluoride (NF3) Market Outlook:

The global market for Nitrogen Trifluoride (NF3) was valued at approximately $1,899 million in 2024, with projections indicating a significant growth trajectory, reaching an estimated $4,111 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 11.6% during the forecast period. The Asia-Pacific region stands out as the largest consumer market for NF3, accounting for about 85% of the global revenue. This dominance is largely due to the region's robust electronics manufacturing sector, which heavily relies on NF3 for various applications. Among these applications, semiconductor chips represent the primary market for NF3, making up around 57% of the global market share. The extensive use of NF3 in the semiconductor industry is driven by its effectiveness as a cleaning and etching agent, essential for maintaining the quality and performance of semiconductor devices. As the demand for electronic devices continues to rise, particularly in the Asia-Pacific region, the NF3 market is poised for substantial growth, driven by advancements in technology and the increasing complexity of electronic manufacturing processes.

| Report Metric | Details |

| Report Name | Nitrogen Trifluoride (NF3) Market |

| Accounted market size in year | US$ 1899 million |

| Forecasted market size in 2031 | US$ 4111 million |

| CAGR | 11.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SK Materials, Hyosung, Kanto Denka Kogyo, Merck (Versum Materials), PERIC, Mitsui Chemical, ChemChina, Shandong FeiYuan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |