What is Global Heavy Duty Vehicle Shock Absorber Market?

The Global Heavy Duty Vehicle Shock Absorber Market is a specialized segment within the automotive industry that focuses on the production and distribution of shock absorbers specifically designed for heavy-duty vehicles. These vehicles include trucks, buses, and other large commercial vehicles that require robust and durable components to ensure safety and performance. Shock absorbers play a crucial role in maintaining vehicle stability, comfort, and control by absorbing and dampening the impact of road irregularities and vibrations. The market is driven by the increasing demand for heavy-duty vehicles in various industries such as construction, logistics, and public transportation. Additionally, advancements in shock absorber technology, such as improved materials and innovative designs, are contributing to the growth of this market. Manufacturers are continuously investing in research and development to enhance the performance and longevity of shock absorbers, catering to the evolving needs of end-users. As a result, the Global Heavy Duty Vehicle Shock Absorber Market is expected to witness steady growth, driven by the rising demand for efficient and reliable shock absorption solutions in heavy-duty vehicles.

Single-Tube Shock Absorbers, Twin-Tube Shock Absorbers in the Global Heavy Duty Vehicle Shock Absorber Market:

Single-tube and twin-tube shock absorbers are two primary types of shock absorbers used in the Global Heavy Duty Vehicle Shock Absorber Market, each with distinct characteristics and applications. Single-tube shock absorbers, also known as monotube shock absorbers, consist of a single cylinder that houses both the piston and the hydraulic fluid. This design allows for better heat dissipation, making them suitable for high-performance applications where heat management is crucial. Single-tube shock absorbers offer superior damping performance and are often used in heavy-duty vehicles that operate in demanding conditions, such as off-road trucks and construction vehicles. Their design also allows for more precise tuning, providing enhanced control and stability. On the other hand, twin-tube shock absorbers feature two cylinders: an inner cylinder that contains the piston and hydraulic fluid, and an outer cylinder that serves as a reservoir for excess fluid. This design is more common in standard heavy-duty vehicles due to its cost-effectiveness and durability. Twin-tube shock absorbers provide a comfortable ride by effectively absorbing road vibrations and impacts, making them ideal for buses and long-haul trucks that prioritize passenger comfort. While they may not offer the same level of performance as single-tube shock absorbers, twin-tube shock absorbers are known for their reliability and ability to handle a wide range of driving conditions. In the Global Heavy Duty Vehicle Shock Absorber Market, the choice between single-tube and twin-tube shock absorbers depends on various factors, including the specific requirements of the vehicle, the operating environment, and budget considerations. Manufacturers are continually innovating to improve the performance and durability of both types of shock absorbers, ensuring they meet the diverse needs of heavy-duty vehicle operators. As the market evolves, advancements in materials and technology are expected to further enhance the capabilities of single-tube and twin-tube shock absorbers, providing even greater value to end-users.

Truck, Bus, Others in the Global Heavy Duty Vehicle Shock Absorber Market:

The usage of shock absorbers in the Global Heavy Duty Vehicle Shock Absorber Market is critical across various applications, including trucks, buses, and other heavy-duty vehicles. In trucks, shock absorbers are essential for maintaining stability and control, especially when carrying heavy loads over long distances. They help absorb the impact of road irregularities, reducing wear and tear on the vehicle and ensuring a smoother ride for the driver. This is particularly important in the logistics and transportation industry, where trucks are often required to travel across diverse terrains and weather conditions. In buses, shock absorbers play a vital role in enhancing passenger comfort and safety. Buses are designed to transport large numbers of passengers, and a smooth ride is crucial to ensure a pleasant travel experience. Shock absorbers help minimize vibrations and jolts, providing a comfortable journey for passengers and reducing driver fatigue. This is especially important in public transportation, where buses operate on fixed routes and schedules, often in urban environments with varying road conditions. In addition to trucks and buses, shock absorbers are also used in other heavy-duty vehicles, such as construction equipment and agricultural machinery. These vehicles operate in challenging environments and require robust shock absorption solutions to maintain performance and reliability. Shock absorbers help protect the vehicle's components from damage caused by constant vibrations and impacts, extending the lifespan of the equipment and reducing maintenance costs. Overall, the Global Heavy Duty Vehicle Shock Absorber Market plays a crucial role in ensuring the safety, comfort, and efficiency of heavy-duty vehicles across various industries. As the demand for these vehicles continues to grow, the importance of high-quality shock absorbers in maintaining vehicle performance and reliability cannot be overstated.

Global Heavy Duty Vehicle Shock Absorber Market Outlook:

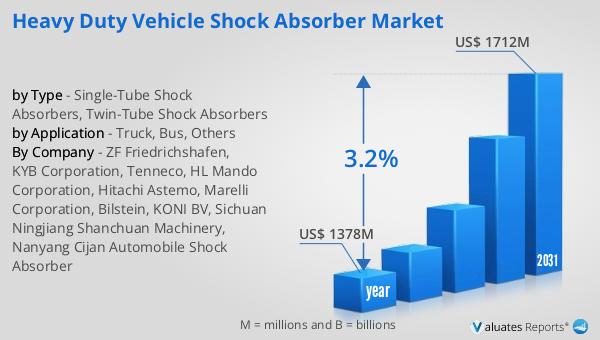

In 2024, the global market for Heavy Duty Vehicle Shock Absorbers was valued at approximately $1,378 million. This market is anticipated to expand, reaching an estimated size of $1,712 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. The steady increase in market size reflects the rising demand for heavy-duty vehicles across various sectors, including transportation, construction, and public transit. As industries continue to expand and infrastructure projects proliferate, the need for reliable and efficient shock absorbers becomes increasingly critical. This growth is also driven by technological advancements in shock absorber design and materials, which enhance performance and durability. Manufacturers are focusing on developing innovative solutions to meet the evolving needs of heavy-duty vehicle operators, ensuring that shock absorbers can withstand the rigors of demanding environments. As a result, the Global Heavy Duty Vehicle Shock Absorber Market is poised for continued growth, driven by the increasing demand for high-performance shock absorption solutions in heavy-duty vehicles.

| Report Metric | Details |

| Report Name | Heavy Duty Vehicle Shock Absorber Market |

| Accounted market size in year | US$ 1378 million |

| Forecasted market size in 2031 | US$ 1712 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ZF Friedrichshafen, KYB Corporation, Tenneco, HL Mando Corporation, Hitachi Astemo, Marelli Corporation, Bilstein, KONI BV, Sichuan Ningjiang Shanchuan Machinery, Nanyang Cijan Automobile Shock Absorber |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |