What is Global Automotive Brazed Composite Aluminum Sheet Market?

The Global Automotive Brazed Composite Aluminum Sheet Market is a specialized segment within the broader automotive materials industry. This market focuses on the production and application of aluminum sheets that are bonded using a brazing process. Brazing is a technique that involves joining metals by melting and flowing a filler metal into the joint, which has a lower melting point than the workpieces. These aluminum sheets are particularly valued in the automotive industry for their lightweight properties, which contribute to improved fuel efficiency and reduced emissions. The composite nature of these sheets means they are engineered to offer enhanced strength and durability, making them suitable for various automotive applications. As the automotive industry continues to prioritize sustainability and efficiency, the demand for such advanced materials is expected to grow. These sheets are used in various components, including heat exchangers, body panels, and interior structures, providing a balance of performance and cost-effectiveness. The market is driven by technological advancements in material science and the increasing adoption of electric vehicles, which require lightweight materials to maximize battery efficiency. Overall, the Global Automotive Brazed Composite Aluminum Sheet Market plays a crucial role in the evolution of modern automotive design and manufacturing.

3003 Aluminum Plate, 4045 Aluminum Plate, Others in the Global Automotive Brazed Composite Aluminum Sheet Market:

The Global Automotive Brazed Composite Aluminum Sheet Market includes various types of aluminum plates, each with distinct properties and applications. Among these, the 3003 Aluminum Plate is widely recognized for its excellent corrosion resistance and good workability. It is an alloy that primarily contains manganese, which enhances its strength compared to pure aluminum. This makes the 3003 Aluminum Plate suitable for applications where moderate strength and good corrosion resistance are required, such as in automotive heat exchangers and fuel tanks. Its ability to withstand harsh environmental conditions without significant degradation makes it a preferred choice in the automotive industry. On the other hand, the 4045 Aluminum Plate is known for its high thermal conductivity and excellent brazing characteristics. It is often used as a cladding layer in brazed aluminum heat exchangers, where efficient heat transfer is critical. The 4045 alloy is typically combined with other aluminum alloys to create a composite material that offers both structural integrity and superior thermal performance. This makes it ideal for use in radiators, condensers, and other components of the vehicle's cooling system. The "Others" category in this market includes a variety of aluminum alloys that are tailored for specific applications. These may include high-strength alloys used in structural components or specialized alloys designed for enhanced formability and surface finish. Each of these alloys is developed to meet the unique demands of automotive manufacturing, where factors such as weight reduction, cost efficiency, and performance are paramount. The choice of aluminum plate depends on the specific requirements of the application, including mechanical properties, thermal performance, and resistance to environmental factors. As the automotive industry continues to evolve, the development of new aluminum alloys and composite materials is expected to play a significant role in meeting the challenges of modern vehicle design. The ongoing research and innovation in this field aim to enhance the properties of aluminum plates, making them even more versatile and effective in automotive applications. This includes efforts to improve the recyclability of aluminum materials, which aligns with the industry's focus on sustainability and environmental responsibility. Overall, the diverse range of aluminum plates available in the Global Automotive Brazed Composite Aluminum Sheet Market provides manufacturers with the flexibility to choose materials that best suit their needs, contributing to the advancement of automotive technology and design.

Heat Exchange System, Body Shells, Automotive Interiors, Others in the Global Automotive Brazed Composite Aluminum Sheet Market:

The Global Automotive Brazed Composite Aluminum Sheet Market finds extensive usage in various areas of automotive manufacturing, each with specific requirements and benefits. In the realm of Heat Exchange Systems, these aluminum sheets are indispensable due to their excellent thermal conductivity and lightweight nature. Heat exchangers, such as radiators and condensers, rely on the efficient transfer of heat to maintain optimal engine temperatures and ensure vehicle performance. The brazed composite aluminum sheets used in these systems are designed to maximize heat dissipation while minimizing weight, contributing to improved fuel efficiency and reduced emissions. Additionally, their corrosion resistance ensures longevity and reliability, even in harsh operating conditions. In the construction of Body Shells, the lightweight properties of aluminum sheets are particularly advantageous. Reducing the overall weight of the vehicle is a critical factor in enhancing fuel efficiency and performance. Brazed composite aluminum sheets offer the strength and durability needed for structural components while allowing for significant weight savings compared to traditional steel. This not only improves the vehicle's energy efficiency but also enhances handling and acceleration. Furthermore, the use of aluminum in body shells contributes to improved crash safety, as the material can absorb and dissipate energy effectively during collisions. Automotive Interiors also benefit from the use of brazed composite aluminum sheets. These materials are used in various interior components, such as dashboards, door panels, and seat structures, where their lightweight and formability allow for innovative design possibilities. The ability to create complex shapes and contours with aluminum sheets enables manufacturers to produce aesthetically pleasing and functional interior elements. Moreover, the recyclability of aluminum aligns with the industry's push towards sustainable manufacturing practices, making it an attractive choice for interior applications. Beyond these specific areas, the Global Automotive Brazed Composite Aluminum Sheet Market also serves other applications within the automotive sector. This includes components such as fuel tanks, suspension systems, and chassis parts, where the combination of strength, weight reduction, and corrosion resistance is essential. The versatility of aluminum sheets allows manufacturers to tailor materials to meet the unique demands of each application, ensuring optimal performance and cost-effectiveness. As the automotive industry continues to evolve, the role of brazed composite aluminum sheets is expected to expand, driven by the need for lightweight, efficient, and sustainable materials. The ongoing development of new alloys and manufacturing techniques will further enhance the capabilities of these materials, supporting the industry's transition towards more environmentally friendly and technologically advanced vehicles.

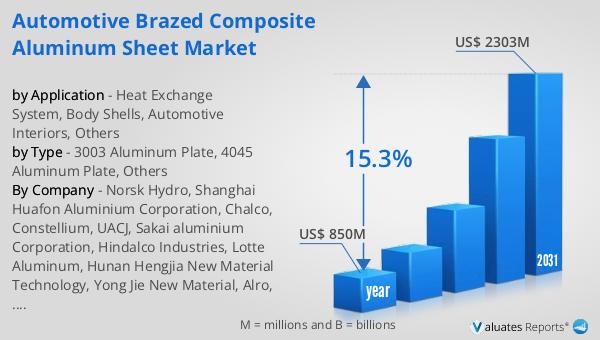

Global Automotive Brazed Composite Aluminum Sheet Market Outlook:

The global market for Automotive Brazed Composite Aluminum Sheet was valued at $850 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $2,303 million by 2031. This impressive growth trajectory represents a compound annual growth rate (CAGR) of 15.3% over the forecast period. This expansion is indicative of the increasing demand for lightweight and efficient materials in the automotive industry, driven by the need to improve fuel efficiency and reduce emissions. As automotive manufacturers continue to innovate and develop new vehicle models, the demand for advanced materials like brazed composite aluminum sheets is expected to rise. These materials offer a combination of strength, durability, and lightweight properties, making them ideal for various automotive applications. The projected growth of this market reflects the broader trends in the automotive industry, where sustainability and efficiency are becoming increasingly important. As the market evolves, manufacturers are likely to invest in research and development to enhance the properties of aluminum sheets, ensuring they meet the changing needs of the industry. This growth also highlights the potential for new opportunities and applications for brazed composite aluminum sheets, as the automotive sector continues to prioritize innovation and environmental responsibility.

| Report Metric | Details |

| Report Name | Automotive Brazed Composite Aluminum Sheet Market |

| Accounted market size in year | US$ 850 million |

| Forecasted market size in 2031 | US$ 2303 million |

| CAGR | 15.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Norsk Hydro, Shanghai Huafon Aluminium Corporation, Chalco, Constellium, UACJ, Sakai aluminium Corporation, Hindalco Industries, Lotte Aluminum, Hunan Hengjia New Material Technology, Yong Jie New Material, Alro, Yinbang Clad Material, Fives |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |