What is Global Non-contact Confocal Chromatic Displacement Sensors Market?

The Global Non-contact Confocal Chromatic Displacement Sensors Market is a specialized segment within the broader sensor industry, focusing on advanced measurement technologies that do not require physical contact with the object being measured. These sensors utilize the principle of confocal chromatic imaging, which involves the use of a multi-wavelength light source to measure displacement, distance, and thickness with high precision. The technology is particularly advantageous in environments where traditional contact-based measurement methods could damage the object or where high precision is required. These sensors are widely used in various industries, including automotive, aerospace, and medical, due to their ability to provide accurate measurements even in challenging conditions. The market for these sensors is driven by the increasing demand for precision in manufacturing and quality control processes, as well as the growing adoption of automation across industries. As industries continue to evolve and require more sophisticated measurement solutions, the demand for non-contact confocal chromatic displacement sensors is expected to grow, offering opportunities for innovation and development in this niche market.

1.0-2.5mm, 2.5-5.0mm, Others in the Global Non-contact Confocal Chromatic Displacement Sensors Market:

In the Global Non-contact Confocal Chromatic Displacement Sensors Market, the measurement range is a critical factor that determines the suitability of a sensor for specific applications. The range categories, such as 1.0-2.5mm, 2.5-5.0mm, and others, represent the distance over which the sensor can accurately measure displacement without physical contact. Sensors with a range of 1.0-2.5mm are typically used in applications requiring high precision over short distances. These might include tasks like measuring the thickness of thin films or coatings, where even minor deviations can significantly impact product quality. The precision offered by these sensors makes them ideal for industries like electronics, where components are often small and require meticulous quality control. On the other hand, sensors with a range of 2.5-5.0mm are suitable for applications that require a balance between precision and a slightly longer measurement range. These sensors are often used in the automotive industry, where they can measure the displacement of larger components or assemblies. The ability to measure over a longer range without sacrificing accuracy is crucial in ensuring that parts fit together correctly and function as intended. Beyond these specific ranges, the "Others" category includes sensors with either shorter or longer measurement capabilities, catering to niche applications that require unique specifications. For instance, in the aerospace industry, sensors with extended ranges might be necessary to measure the displacement of large structural components, ensuring they meet stringent safety and performance standards. Similarly, in industrial automation, sensors with varying ranges are used to monitor and control processes, ensuring efficiency and reducing the risk of errors. The versatility of non-contact confocal chromatic displacement sensors across different range categories highlights their importance in modern manufacturing and quality assurance processes. As industries continue to demand higher precision and efficiency, the development of sensors with tailored measurement ranges will be crucial in meeting these evolving needs. The ability to customize sensor specifications to suit specific applications not only enhances performance but also drives innovation within the market, encouraging manufacturers to explore new possibilities and applications for this advanced technology.

Aerospace and Defense, Automotive, Industrial Automation, Medical, Others in the Global Non-contact Confocal Chromatic Displacement Sensors Market:

The usage of Global Non-contact Confocal Chromatic Displacement Sensors spans several critical industries, each benefiting from the unique capabilities of these advanced measurement tools. In the aerospace and defense sector, these sensors are indispensable for ensuring the precision and reliability of components used in aircraft and defense systems. The ability to measure displacement and thickness with high accuracy is crucial in this industry, where even minor deviations can have significant safety implications. Non-contact sensors are particularly valuable in this context, as they can measure delicate or sensitive components without causing damage. In the automotive industry, these sensors play a vital role in quality control and assembly processes. They are used to measure the alignment and fit of various components, ensuring that vehicles meet stringent safety and performance standards. The non-contact nature of these sensors allows for measurements to be taken without interfering with the components, which is essential in maintaining the integrity of the parts being measured. Industrial automation is another area where these sensors are widely used. They are employed in automated production lines to monitor and control processes, ensuring that products are manufactured to precise specifications. The ability to provide real-time feedback on measurements allows for immediate adjustments, reducing waste and improving efficiency. In the medical field, non-contact confocal chromatic displacement sensors are used in the development and manufacturing of medical devices. Their precision is crucial in ensuring that devices meet the necessary standards for safety and effectiveness. Additionally, these sensors can be used in research and development to measure biological samples or components without contamination. Beyond these specific industries, the versatility of these sensors allows them to be used in a variety of other applications. Whether it's in electronics, where they measure the thickness of circuit boards, or in the production of consumer goods, where they ensure product consistency, the demand for precise, non-contact measurement solutions continues to grow. As industries evolve and the need for precision increases, the role of non-contact confocal chromatic displacement sensors will become even more critical, driving innovation and development across various sectors.

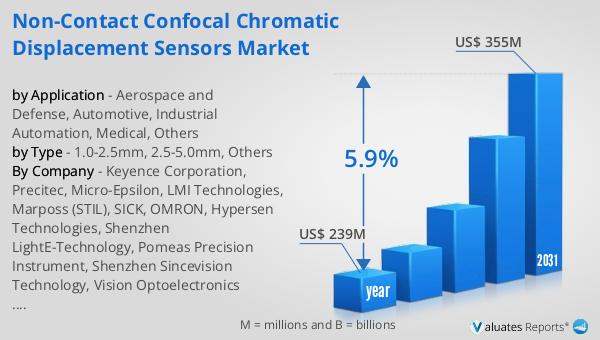

Global Non-contact Confocal Chromatic Displacement Sensors Market Outlook:

The outlook for the Global Non-contact Confocal Chromatic Displacement Sensors Market indicates a promising future, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 239 million, reflecting the increasing demand for precision measurement solutions across various industries. By 2031, the market is projected to reach a revised size of US$ 355 million, growing at a compound annual growth rate (CAGR) of 5.9% during the forecast period. This growth is driven by several factors, including the rising adoption of automation in manufacturing processes and the need for high-precision measurement tools in quality control. As industries continue to prioritize efficiency and accuracy, the demand for non-contact confocal chromatic displacement sensors is expected to rise. These sensors offer a unique combination of precision and non-invasiveness, making them ideal for applications where traditional contact-based measurement methods are unsuitable. The market's expansion also reflects the ongoing innovation within the sensor industry, with manufacturers developing new technologies and solutions to meet the evolving needs of their customers. As the market grows, it presents opportunities for companies to explore new applications and industries, further driving the adoption of these advanced measurement tools. The future of the Global Non-contact Confocal Chromatic Displacement Sensors Market looks bright, with continued growth and development anticipated in the years to come.

| Report Metric | Details |

| Report Name | Non-contact Confocal Chromatic Displacement Sensors Market |

| Accounted market size in year | US$ 239 million |

| Forecasted market size in 2031 | US$ 355 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Keyence Corporation, Precitec, Micro-Epsilon, LMI Technologies, Marposs (STIL), SICK, OMRON, Hypersen Technologies, Shenzhen LightE-Technology, Pomeas Precision Instrument, Shenzhen Sincevision Technology, Vision Optoelectronics Technology, Seizet Technology, Acuity Laser, Proldv Optical Technology, Creative Visual Intellgence |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |