What is Global Non-Contacting Displacement Sensors Market?

The Global Non-Contacting Displacement Sensors Market refers to the industry focused on the development, production, and distribution of sensors that measure the distance or displacement of an object without making physical contact. These sensors are crucial in various applications where contact-based measurement could lead to wear and tear or where the object is inaccessible. They are widely used in industries such as automotive, aerospace, manufacturing, and electronics, providing precise and reliable measurements. The market is driven by the increasing demand for automation and precision in industrial processes, as well as advancements in sensor technology that enhance accuracy and efficiency. Non-contacting displacement sensors come in various types, including laser, magnetostrictive, photoelectric, ultrasonic, and eddy current sensors, each offering unique advantages depending on the application. As industries continue to evolve and require more sophisticated measurement solutions, the demand for these sensors is expected to grow, making the Global Non-Contacting Displacement Sensors Market a vital component of modern industrial technology.

Laser Sensor, Magnetostrictive Sensor, Photoelectric Sensor, Ultrasonic Sensor, Eddy Current Sensor in the Global Non-Contacting Displacement Sensors Market:

Laser sensors are a prominent type of non-contacting displacement sensor, known for their high precision and speed. They use laser beams to measure the distance to an object, making them ideal for applications requiring high accuracy, such as in quality control and inspection processes. Laser sensors can operate over long distances and are unaffected by the color or texture of the target surface, which makes them versatile in various industrial settings. Magnetostrictive sensors, on the other hand, utilize the magnetostrictive effect, where a magnetic field causes a change in the dimensions of a material. These sensors are highly reliable and durable, often used in harsh environments where other sensors might fail. They are commonly found in hydraulic cylinders and other applications requiring robust performance. Photoelectric sensors use light to detect the presence or absence of an object, making them suitable for applications like counting, positioning, and detecting small objects. They are widely used in automation and packaging industries due to their fast response time and ability to detect transparent or shiny objects. Ultrasonic sensors employ sound waves to measure distance, offering a non-invasive way to detect objects regardless of their material, color, or transparency. These sensors are particularly useful in applications where dust, dirt, or moisture might interfere with other types of sensors. Lastly, eddy current sensors work by measuring the change in impedance caused by the proximity of a conductive target. They are known for their high precision and are often used in applications requiring fine measurements, such as in the aerospace industry for detecting cracks or flaws in metal surfaces. Each of these sensors plays a crucial role in the Global Non-Contacting Displacement Sensors Market, catering to diverse industrial needs and contributing to the advancement of technology across various sectors.

Automotive, Aerospace & Military, Industrial Manufacturing, Electronics, Others in the Global Non-Contacting Displacement Sensors Market:

In the automotive industry, non-contacting displacement sensors are essential for ensuring the safety and efficiency of vehicles. They are used in applications such as measuring the position of components, detecting wear and tear, and monitoring the alignment of parts. These sensors help in maintaining the quality and performance of vehicles, contributing to the development of advanced driver-assistance systems (ADAS) and autonomous vehicles. In the aerospace and military sectors, these sensors are critical for precision measurement and monitoring of aircraft components, ensuring the safety and reliability of flights. They are used in applications such as monitoring the structural integrity of aircraft, detecting potential failures, and enhancing the performance of military equipment. In industrial manufacturing, non-contacting displacement sensors are used for quality control, process automation, and equipment monitoring. They help in improving the efficiency and accuracy of manufacturing processes, reducing downtime, and ensuring the production of high-quality products. In the electronics industry, these sensors are used for precise measurement and alignment of components, ensuring the functionality and reliability of electronic devices. They are also used in the production of semiconductors, where precision is crucial. Other industries, such as healthcare and energy, also benefit from the use of non-contacting displacement sensors, where they are used for applications like monitoring the position of medical equipment or measuring the displacement of energy infrastructure. Overall, the Global Non-Contacting Displacement Sensors Market plays a vital role in enhancing the performance and efficiency of various industries, driving innovation and technological advancement.

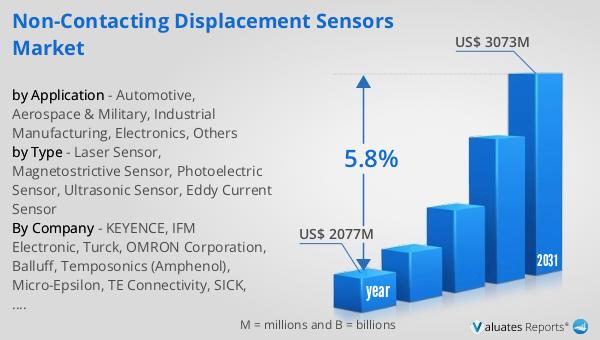

Global Non-Contacting Displacement Sensors Market Outlook:

The global market for non-contacting displacement sensors was valued at $2,077 million in 2024 and is anticipated to grow to a revised size of $3,073 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period. This growth indicates a robust demand for these sensors across various industries, driven by the need for precision and efficiency in measurement applications. Despite the market's expansion, it remains relatively fragmented, with the top five companies holding approximately 30% of the market share. This fragmentation suggests a competitive landscape where numerous players are striving to innovate and capture market share. The increasing adoption of automation and advanced technologies in industries such as automotive, aerospace, and manufacturing is expected to fuel the demand for non-contacting displacement sensors. As companies continue to invest in research and development to enhance sensor capabilities, the market is poised for significant growth. The diverse applications of these sensors, from quality control in manufacturing to safety monitoring in aerospace, underscore their importance in modern industrial processes. As a result, the Global Non-Contacting Displacement Sensors Market is set to play a crucial role in shaping the future of industrial technology.

| Report Metric | Details |

| Report Name | Non-Contacting Displacement Sensors Market |

| Accounted market size in year | US$ 2077 million |

| Forecasted market size in 2031 | US$ 3073 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KEYENCE, IFM Electronic, Turck, OMRON Corporation, Balluff, Temposonics (Amphenol), Micro-Epsilon, TE Connectivity, SICK, Panasonic, Honeywell, Baumer, Optex-FA, Solartron (Ametek), HBK, Pepperl+Fuchs, Schreiber Messtechnik GmbH, Kodenshi, MTI Instruments (VITREK), Burster, MEGATRON, NanJing GOVA Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |