What is Global Non-contact Inductive Displacement Sensors Market?

The Global Non-contact Inductive Displacement Sensors Market refers to the industry focused on the production and distribution of sensors that measure displacement without physical contact. These sensors operate on the principle of electromagnetic induction, detecting changes in position by measuring variations in inductance. They are highly valued for their precision, durability, and ability to function in harsh environments where contact-based sensors might fail. The market encompasses a wide range of applications across various industries, including automotive, aerospace, and manufacturing, where precise measurement is crucial. The demand for these sensors is driven by the need for accurate and reliable measurement solutions that can withstand extreme conditions and provide long-term stability. As industries continue to automate and seek more efficient processes, the role of non-contact inductive displacement sensors becomes increasingly significant. Their ability to deliver high-resolution measurements without wear and tear makes them an attractive choice for modern industrial applications. The market is characterized by continuous innovation, with manufacturers striving to enhance sensor capabilities and expand their application scope. This ongoing development ensures that non-contact inductive displacement sensors remain a vital component in the toolkit of industries aiming for precision and efficiency.

Split Type, Integrated Type in the Global Non-contact Inductive Displacement Sensors Market:

In the Global Non-contact Inductive Displacement Sensors Market, sensors are primarily categorized into two types: Split Type and Integrated Type. Split Type sensors consist of separate components for the sensing element and the electronics. This separation allows for greater flexibility in installation, as the sensing element can be placed in environments that may be too harsh for the electronics. This type is particularly useful in applications where space is limited or where the sensor needs to be positioned in a location that is difficult to access. The separation also facilitates easier maintenance and replacement of individual components, which can be a significant advantage in industrial settings where downtime needs to be minimized. On the other hand, Integrated Type sensors combine the sensing element and the electronics into a single unit. This integration simplifies installation and reduces the overall footprint of the sensor system. Integrated sensors are often more compact and can be more cost-effective due to the reduced need for additional components and wiring. They are ideal for applications where space is at a premium and where the environment is not overly harsh. The choice between Split Type and Integrated Type sensors depends largely on the specific requirements of the application, including environmental conditions, space constraints, and maintenance considerations. Both types offer unique advantages and are designed to meet the diverse needs of industries relying on precise displacement measurement. As technology advances, both Split Type and Integrated Type sensors continue to evolve, offering improved performance, greater reliability, and enhanced functionality. Manufacturers are constantly innovating to address the challenges faced by industries, ensuring that these sensors remain at the forefront of measurement technology. The ongoing development in sensor technology is driven by the increasing demand for precision and efficiency in industrial processes. As industries strive to optimize their operations, the role of non-contact inductive displacement sensors becomes ever more critical. The ability to provide accurate, reliable measurements without physical contact makes these sensors an indispensable tool in the modern industrial landscape. Whether in automotive manufacturing, aerospace engineering, or any other field requiring precise measurement, the choice between Split Type and Integrated Type sensors offers flexibility and adaptability to meet the specific needs of each application.

Aerospace, Automotive, Electric Power, Petroleum and Chemicals, Others in the Global Non-contact Inductive Displacement Sensors Market:

The Global Non-contact Inductive Displacement Sensors Market finds extensive usage across various industries, including Aerospace, Automotive, Electric Power, Petroleum and Chemicals, and others. In the Aerospace industry, these sensors are crucial for ensuring the precision and reliability of various components and systems. They are used to measure the displacement of critical parts, ensuring that aircraft operate safely and efficiently. The ability to function in extreme conditions, such as high altitudes and varying temperatures, makes these sensors ideal for aerospace applications. In the Automotive industry, non-contact inductive displacement sensors are used to enhance the performance and safety of vehicles. They are employed in systems such as suspension, braking, and engine management, where precise measurement is essential for optimal performance. The sensors help in monitoring and controlling various parameters, contributing to the overall efficiency and safety of vehicles. In the Electric Power sector, these sensors are used to monitor the position of components in power generation and distribution systems. They play a vital role in ensuring the smooth operation of equipment, helping to prevent failures and reduce maintenance costs. The ability to provide accurate measurements without physical contact is particularly beneficial in high-voltage environments where safety is a concern. In the Petroleum and Chemicals industry, non-contact inductive displacement sensors are used to monitor the position of valves, pumps, and other critical components. The harsh environments often encountered in this industry, such as high temperatures and corrosive substances, require sensors that can withstand such conditions while providing reliable measurements. These sensors help in maintaining the efficiency and safety of operations, reducing the risk of accidents and equipment failure. Beyond these industries, non-contact inductive displacement sensors are used in a variety of other applications, including manufacturing, robotics, and medical devices. Their versatility and reliability make them suitable for any application requiring precise, non-contact measurement. As industries continue to evolve and seek more efficient and reliable solutions, the demand for non-contact inductive displacement sensors is expected to grow. Their ability to provide accurate measurements in challenging environments makes them an essential tool for modern industrial applications.

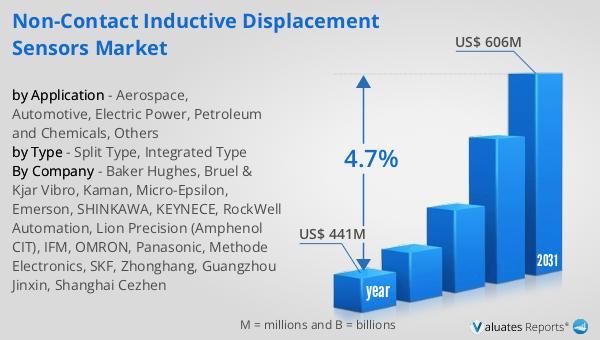

Global Non-contact Inductive Displacement Sensors Market Outlook:

The outlook for the Global Non-contact Inductive Displacement Sensors Market indicates a promising future. In 2024, the market was valued at approximately $441 million. By 2031, it is anticipated to expand to a revised size of around $606 million, reflecting a compound annual growth rate (CAGR) of 4.7% over the forecast period. This growth trajectory underscores the increasing demand for precise and reliable measurement solutions across various industries. The market's expansion is driven by the continuous advancements in sensor technology, which enhance performance and broaden application possibilities. Industries such as automotive, aerospace, and manufacturing are increasingly adopting these sensors to improve efficiency and accuracy in their operations. The ability of non-contact inductive displacement sensors to deliver high-resolution measurements without physical contact makes them an attractive choice for applications where precision is paramount. As industries strive for greater automation and efficiency, the role of these sensors becomes even more critical. The projected growth of the market reflects the ongoing need for innovative measurement solutions that can meet the demands of modern industrial processes. With continuous innovation and development, the Global Non-contact Inductive Displacement Sensors Market is poised to play a vital role in shaping the future of industrial measurement technology.

| Report Metric | Details |

| Report Name | Non-contact Inductive Displacement Sensors Market |

| Accounted market size in year | US$ 441 million |

| Forecasted market size in 2031 | US$ 606 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Baker Hughes, Bruel & Kjar Vibro, Kaman, Micro-Epsilon, Emerson, SHINKAWA, KEYNECE, RockWell Automation, Lion Precision (Amphenol CIT), IFM, OMRON, Panasonic, Methode Electronics, SKF, Zhonghang, Guangzhou Jinxin, Shanghai Cezhen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |