What is Global Stepper Motor Market?

The global stepper motor market is a dynamic and evolving sector that plays a crucial role in various industries by providing precise control of motion. Stepper motors are electromechanical devices that convert electrical pulses into discrete mechanical movements. They are widely used in applications requiring precise positioning and speed control, such as robotics, CNC machines, and 3D printers. The market for stepper motors is driven by the increasing demand for automation and the need for high-performance motors in industrial applications. These motors are known for their reliability, durability, and ability to operate in harsh environments, making them ideal for a wide range of applications. The global market is characterized by a diverse range of products, including variable-reluctance, permanent magnet, and hybrid stepper motors, each offering unique advantages. As industries continue to embrace automation and advanced manufacturing techniques, the demand for stepper motors is expected to grow, driven by technological advancements and the need for efficient and precise motion control solutions. The market is also influenced by factors such as the rise of smart manufacturing, the integration of IoT technologies, and the increasing focus on energy efficiency.

Variable-reluctance (VR), Permanent Magnet (PM), Hybrid (HB) in the Global Stepper Motor Market:

In the global stepper motor market, three main types of stepper motors are prevalent: Variable-reluctance (VR), Permanent Magnet (PM), and Hybrid (HB) stepper motors. Each type has distinct characteristics and applications. Variable-reluctance stepper motors are known for their simple construction and cost-effectiveness. They operate by using a rotor made of soft iron that aligns with the magnetic field generated by the stator. This type of motor is often used in applications where cost is a significant factor and precision is not the primary concern. However, VR motors can suffer from lower torque and less precision compared to other types. Permanent Magnet stepper motors, on the other hand, use a rotor with permanent magnets, which allows for better torque and precision. These motors are commonly used in applications requiring higher performance, such as in office automation equipment and small robotics. The presence of permanent magnets in the rotor enhances the motor's efficiency and reliability. Hybrid stepper motors combine the features of both VR and PM motors, offering high precision and torque. They are the most popular type of stepper motor in the market due to their versatility and performance. Hybrid motors are used in a wide range of applications, from industrial automation to medical devices, where precision and reliability are critical. The global stepper motor market is driven by the increasing demand for these motors in various industries, as they provide an effective solution for precise motion control. As technology advances, the capabilities of stepper motors continue to improve, making them an essential component in modern automation systems. The choice between VR, PM, and HB stepper motors depends on the specific requirements of the application, such as cost, precision, and torque. Each type of motor offers unique benefits, and understanding these differences is crucial for selecting the right motor for a given application. As industries continue to evolve and embrace automation, the demand for stepper motors is expected to grow, driven by the need for efficient and reliable motion control solutions.

CNC Machine Tool, Industrial Automation, Office Automation, Printing Equipment, Others in the Global Stepper Motor Market:

Stepper motors are integral to various applications, providing precise control and reliability. In CNC machine tools, stepper motors are essential for achieving accurate positioning and movement. They enable the precise control of cutting tools, ensuring high-quality machining and manufacturing processes. The ability to control speed and position with high precision makes stepper motors ideal for CNC applications, where even the slightest error can lead to significant defects in the final product. In industrial automation, stepper motors are used to automate processes, improve efficiency, and reduce human intervention. They are employed in conveyor systems, robotic arms, and assembly lines, where precise motion control is crucial for maintaining productivity and quality. The reliability and durability of stepper motors make them suitable for harsh industrial environments, where they can operate continuously without significant maintenance. In office automation, stepper motors are used in printers, scanners, and copiers, where they provide precise control of paper movement and print head positioning. The ability to deliver consistent and accurate performance is essential in office equipment, where high-speed and high-quality output are required. In printing equipment, stepper motors ensure the precise movement of print heads and paper, resulting in high-quality prints with accurate color registration. The use of stepper motors in printing applications allows for high-speed operation and precise control, essential for meeting the demands of modern printing processes. Beyond these specific applications, stepper motors are also used in various other fields, such as medical devices, automotive systems, and consumer electronics. In medical devices, stepper motors provide precise control of movement in equipment such as MRI machines and infusion pumps. In automotive systems, they are used in applications such as throttle control and headlight adjustment, where precise positioning is required. In consumer electronics, stepper motors are used in devices such as cameras and projectors, where they enable precise control of lenses and other components. The versatility and reliability of stepper motors make them an essential component in a wide range of applications, driving their demand in the global market. As industries continue to innovate and adopt new technologies, the use of stepper motors is expected to grow, driven by the need for precise and reliable motion control solutions.

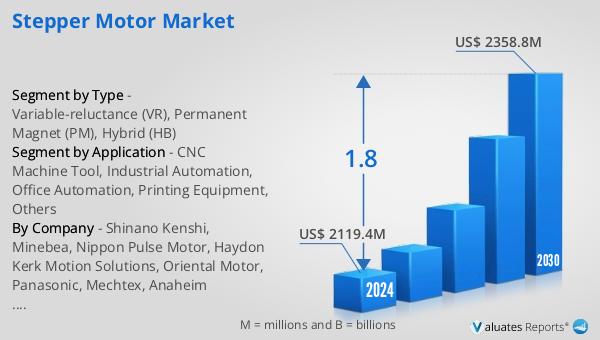

Global Stepper Motor Market Outlook:

In 2024, the global stepper motor market was valued at approximately US$ 2,154 million. Projections indicate that by 2031, this market is expected to expand to around US$ 2,436 million, reflecting a compound annual growth rate (CAGR) of 1.8% during the forecast period from 2025 to 2031. China stands out as the dominant player in the stepper motor market, commanding a substantial 63% market share. This significant share underscores China's pivotal role in the global stepper motor industry, driven by its robust manufacturing capabilities and extensive industrial base. Despite the vastness of the market, the top three companies collectively hold only about 4% of the market share, highlighting the fragmented nature of the industry and the presence of numerous players. This fragmentation suggests a competitive landscape where innovation and specialization are key to gaining a competitive edge. The growth of the stepper motor market is fueled by the increasing demand for automation and precision in various industries, including manufacturing, healthcare, and consumer electronics. As industries continue to evolve and embrace advanced technologies, the need for efficient and reliable motion control solutions is expected to drive the demand for stepper motors. The market's growth trajectory is also influenced by factors such as technological advancements, the integration of IoT technologies, and the increasing focus on energy efficiency. As the global economy continues to recover and industries invest in automation and modernization, the stepper motor market is poised for steady growth, offering opportunities for both established players and new entrants.

| Report Metric | Details |

| Report Name | Stepper Motor Market |

| CAGR | 1.8% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Shinano Kenshi, Minebea, Nippon Pulse Motor, Haydon Kerk Motion Solutions, Oriental Motor, Panasonic, Mechtex, Anaheim Automation, ElectroCraft, Nanotec Electronic, Kollemorgen, Bosch Rexroth, TECO Electro Devices, Changzhou Leili, Moons, Fengyuan Micro & Special Motors, Mige (Jiangte), Zhejiang Founder Motor, Changzhou Baolai Electric Appliance, Hetai Motor, CW Motor, GBM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |