What is Global Machine Vision Linear Array Lights Market?

The Global Machine Vision Linear Array Lights Market is a specialized segment within the broader machine vision industry, focusing on the use of linear array lights to enhance image processing and analysis. These lights are integral to machine vision systems, which are used to automate the inspection and analysis of products in various industries. Linear array lights are designed to provide uniform illumination across a linear field of view, making them ideal for applications that require precise and consistent lighting conditions. This market is driven by the increasing demand for automation and quality control in manufacturing processes, where machine vision systems play a crucial role. Industries such as automotive, electronics, food and beverage, and pharmaceuticals are major users of these systems, as they require high-speed and accurate inspection capabilities. The market is characterized by technological advancements, with manufacturers continuously innovating to improve the performance and efficiency of linear array lights. As industries strive for higher productivity and quality standards, the demand for advanced machine vision solutions, including linear array lights, is expected to grow. This growth is further supported by the increasing adoption of Industry 4.0 practices, which emphasize the integration of digital technologies in manufacturing.

Strobe Type, Continuous Type in the Global Machine Vision Linear Array Lights Market:

In the Global Machine Vision Linear Array Lights Market, two primary types of lighting are utilized: Strobe Type and Continuous Type. Strobe Type lighting involves the use of short, intense bursts of light that are synchronized with the camera's exposure time. This method is particularly effective in high-speed applications where motion blur needs to be minimized. By providing a brief and powerful illumination, strobe lights can capture sharp images of fast-moving objects, making them ideal for industries such as automotive and electronics, where rapid inspection is crucial. The strobe effect also helps in reducing heat generation, as the lights are not continuously on, which can be beneficial in temperature-sensitive environments. On the other hand, Continuous Type lighting provides a steady and constant source of illumination. This type of lighting is suitable for applications where consistent lighting conditions are required over extended periods. Continuous lights are often used in scenarios where the inspection process is slower, or where the objects being inspected are stationary. They offer the advantage of simplicity, as there is no need for synchronization with the camera, and they can be easier to set up and maintain. However, continuous lights may generate more heat compared to strobe lights, which can be a consideration in certain applications. Both types of lighting have their unique advantages and are chosen based on the specific requirements of the inspection task. The choice between strobe and continuous lighting often depends on factors such as the speed of the production line, the nature of the objects being inspected, and the environmental conditions of the inspection area. As the demand for machine vision systems continues to grow, manufacturers are developing more advanced lighting solutions that offer greater flexibility and performance. Innovations in LED technology, for example, have led to the development of lights that can switch between strobe and continuous modes, providing users with the ability to adapt to different inspection scenarios. This versatility is becoming increasingly important as industries seek to optimize their production processes and improve quality control. The Global Machine Vision Linear Array Lights Market is thus characterized by a diverse range of lighting solutions, each tailored to meet the specific needs of different applications. As technology continues to evolve, the market is expected to see further advancements in lighting design and functionality, offering even greater capabilities for machine vision systems.

Bright Field Lighting, Dark Field Lighting in the Global Machine Vision Linear Array Lights Market:

The usage of Global Machine Vision Linear Array Lights Market in Bright Field Lighting and Dark Field Lighting is pivotal for enhancing the quality and accuracy of visual inspections. Bright Field Lighting is a technique where the light source is positioned in such a way that it illuminates the object directly, creating a bright background. This method is particularly effective for detecting surface defects, such as scratches, dents, or other irregularities, as it highlights these imperfections against the bright background. Bright Field Lighting is commonly used in industries like electronics and automotive, where surface quality is critical. The uniform illumination provided by linear array lights ensures that even the smallest defects are visible, allowing for precise quality control. On the other hand, Dark Field Lighting involves positioning the light source at a low angle relative to the object, so that the light reflects off the surface at an angle. This technique is used to detect surface features that are not visible under direct lighting, such as edges, textures, or embossed patterns. Dark Field Lighting is particularly useful in applications where the detection of subtle surface features is required, such as in the inspection of printed circuit boards or the examination of glass surfaces. The contrast created by the dark background and the illuminated features allows for the detection of minute details that would otherwise be missed. Both Bright Field and Dark Field Lighting techniques are essential for achieving high levels of accuracy and reliability in machine vision systems. The choice between these techniques depends on the specific requirements of the inspection task, such as the type of defects to be detected and the nature of the objects being inspected. In many cases, a combination of both techniques is used to provide a comprehensive inspection solution. The versatility of linear array lights makes them ideal for use in both Bright Field and Dark Field Lighting applications, as they can be easily adjusted to provide the desired lighting conditions. As industries continue to demand higher quality standards and more efficient inspection processes, the use of advanced lighting techniques, such as Bright Field and Dark Field Lighting, is expected to increase. The Global Machine Vision Linear Array Lights Market is thus poised for growth, driven by the need for more sophisticated and adaptable lighting solutions that can meet the diverse needs of modern manufacturing environments.

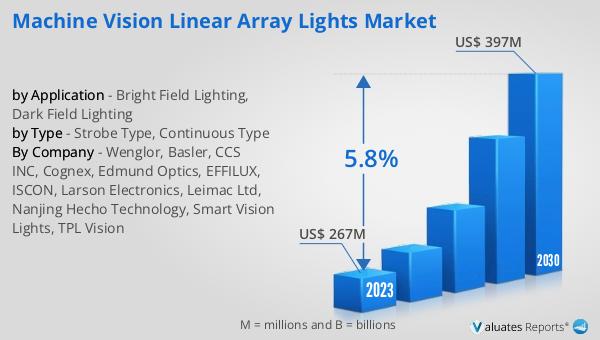

Global Machine Vision Linear Array Lights Market Outlook:

The global market for Machine Vision Linear Array Lights was valued at $283 million in 2024 and is anticipated to expand to a revised size of $418 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% over the forecast period. This growth trajectory underscores the increasing importance of machine vision systems in various industries, as they seek to enhance automation and quality control processes. The steady rise in market value is indicative of the growing adoption of linear array lights, which are integral to the performance of machine vision systems. These lights provide the necessary illumination for accurate image capture and analysis, enabling industries to achieve higher levels of precision and efficiency in their operations. The projected growth in the market is also a testament to the ongoing advancements in lighting technology, which are driving improvements in the performance and versatility of linear array lights. As industries continue to embrace digital transformation and Industry 4.0 practices, the demand for advanced machine vision solutions, including linear array lights, is expected to rise. This trend is further supported by the increasing focus on quality assurance and the need for more efficient inspection processes in manufacturing. The Global Machine Vision Linear Array Lights Market is thus set to experience significant growth, driven by the need for more sophisticated and adaptable lighting solutions that can meet the diverse needs of modern manufacturing environments.

| Report Metric | Details |

| Report Name | Machine Vision Linear Array Lights Market |

| Accounted market size in year | US$ 283 million |

| Forecasted market size in 2031 | US$ 418 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wenglor, Basler, CCS INC, Cognex, Edmund Optics, EFFILUX, ISCON, Larson Electronics, Leimac Ltd, Nanjing Hecho Technology, Smart Vision Lights, TPL Vision |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |