What is Global Non-contact Laser Triangulation Displacement Sensors Market?

The Global Non-contact Laser Triangulation Displacement Sensors Market refers to the industry focused on the development, production, and distribution of sensors that utilize laser triangulation technology to measure displacement without physical contact. These sensors are designed to accurately determine the distance between the sensor and a target object by emitting a laser beam and analyzing the reflected light. This technology is particularly valuable in applications where precision and non-intrusive measurement are critical, such as in manufacturing, quality control, and automation processes. The market for these sensors is driven by the increasing demand for high-precision measurement tools across various industries, including automotive, aerospace, and electronics. As industries continue to automate and seek more efficient ways to monitor and control processes, the adoption of non-contact laser triangulation displacement sensors is expected to grow. These sensors offer advantages such as high accuracy, fast response times, and the ability to measure a wide range of materials and surfaces, making them a versatile solution for modern industrial challenges. The market is characterized by ongoing technological advancements, with manufacturers continually improving sensor capabilities to meet the evolving needs of end-users.

1D, 2D, 3D in the Global Non-contact Laser Triangulation Displacement Sensors Market:

In the realm of Global Non-contact Laser Triangulation Displacement Sensors, the technology is categorized into 1D, 2D, and 3D sensors, each serving distinct purposes and applications. 1D sensors are primarily used for measuring the distance or displacement along a single axis. These sensors are ideal for applications where only one-dimensional measurement is required, such as monitoring the thickness of materials, detecting surface irregularities, or ensuring precise positioning in automated systems. The simplicity and cost-effectiveness of 1D sensors make them a popular choice for many industrial applications where basic displacement measurement is sufficient. Moving to 2D sensors, these devices are capable of measuring displacement across two axes, providing a more comprehensive analysis of the target object's surface. 2D sensors are often employed in applications that require surface profiling, such as inspecting flatness, detecting defects, or measuring the width and height of objects. The ability to capture data in two dimensions allows for more detailed and accurate assessments, making 2D sensors valuable in quality control and inspection processes. Finally, 3D sensors represent the most advanced category, capable of capturing displacement data across three axes. These sensors are essential for applications that demand a complete three-dimensional analysis of an object, such as in robotics, 3D modeling, and complex surface inspections. 3D sensors provide a holistic view of the target, enabling precise measurements of volume, shape, and surface characteristics. The versatility and comprehensive data provided by 3D sensors make them indispensable in industries that require high levels of precision and detail. As technology continues to advance, the capabilities of 1D, 2D, and 3D sensors are expected to expand, offering even greater accuracy and functionality to meet the diverse needs of various industries.

Aerospace and Defense, Automotive, Industrial Automation, Medical, Others in the Global Non-contact Laser Triangulation Displacement Sensors Market:

The Global Non-contact Laser Triangulation Displacement Sensors Market finds extensive usage across several key industries, including Aerospace and Defense, Automotive, Industrial Automation, Medical, and others. In the Aerospace and Defense sector, these sensors are crucial for ensuring the precision and reliability of components and systems. They are used in applications such as monitoring the alignment of aircraft parts, inspecting the surface quality of critical components, and ensuring the accuracy of missile guidance systems. The ability to provide non-contact measurements is particularly valuable in this industry, where even minor deviations can have significant consequences. In the Automotive industry, non-contact laser triangulation displacement sensors play a vital role in quality control and manufacturing processes. They are used to measure the thickness of paint, inspect the alignment of body panels, and ensure the proper fit of components. The sensors' ability to provide fast and accurate measurements helps manufacturers maintain high standards of quality and efficiency. In the realm of Industrial Automation, these sensors are integral to the operation of automated systems and machinery. They are used to monitor the position and movement of parts, detect defects, and ensure the smooth operation of production lines. The sensors' non-contact nature allows them to operate in harsh environments without interfering with the process. In the Medical field, non-contact laser triangulation displacement sensors are used in applications such as measuring the thickness of medical devices, inspecting the surface quality of implants, and ensuring the precision of surgical instruments. The sensors' ability to provide accurate and reliable measurements is critical in this industry, where precision is paramount. Finally, in other industries such as electronics, consumer goods, and construction, these sensors are used for a variety of applications, including inspecting the quality of electronic components, measuring the dimensions of products, and ensuring the accuracy of construction materials. The versatility and precision of non-contact laser triangulation displacement sensors make them an invaluable tool across a wide range of industries.

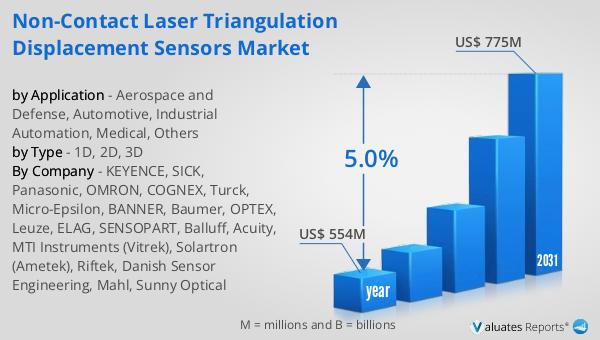

Global Non-contact Laser Triangulation Displacement Sensors Market Outlook:

The global market for Non-contact Laser Triangulation Displacement Sensors was valued at $554 million in 2024, with projections indicating a growth to $775 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.0% over the forecast period. This upward trend is driven by the increasing demand for precise and efficient measurement solutions across various industries. As industries continue to automate and seek more efficient ways to monitor and control processes, the adoption of non-contact laser triangulation displacement sensors is expected to grow. These sensors offer advantages such as high accuracy, fast response times, and the ability to measure a wide range of materials and surfaces, making them a versatile solution for modern industrial challenges. The market is characterized by ongoing technological advancements, with manufacturers continually improving sensor capabilities to meet the evolving needs of end-users. The versatility and precision of non-contact laser triangulation displacement sensors make them an invaluable tool across a wide range of industries. As technology continues to advance, the capabilities of these sensors are expected to expand, offering even greater accuracy and functionality to meet the diverse needs of various industries.

| Report Metric | Details |

| Report Name | Non-contact Laser Triangulation Displacement Sensors Market |

| Accounted market size in year | US$ 554 million |

| Forecasted market size in 2031 | US$ 775 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KEYENCE, SICK, Panasonic, OMRON, COGNEX, Turck, Micro-Epsilon, BANNER, Baumer, OPTEX, Leuze, ELAG, SENSOPART, Balluff, Acuity, MTI Instruments (Vitrek), Solartron (Ametek), Riftek, Danish Sensor Engineering, Mahl, Sunny Optical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |