What is Global Machine Vision Bar Lights Market?

The Global Machine Vision Bar Lights Market is a specialized segment within the broader machine vision industry, focusing on the use of bar lights to enhance the capabilities of machine vision systems. These bar lights are integral components that provide the necessary illumination for cameras and sensors to capture high-quality images and data. Machine vision systems are used in various industries, including manufacturing, automotive, electronics, and pharmaceuticals, to automate processes, improve quality control, and increase efficiency. Bar lights are particularly valued for their ability to provide uniform lighting, which is crucial for accurate image analysis and defect detection. They come in various sizes, colors, and intensities to suit different applications and environments. The market for these lights is driven by the increasing demand for automation and quality assurance in production processes. As industries continue to adopt advanced technologies, the need for reliable and efficient machine vision systems, including bar lights, is expected to grow. This market is characterized by continuous innovation, with manufacturers developing new lighting solutions to meet the evolving needs of their customers. Overall, the Global Machine Vision Bar Lights Market plays a vital role in enhancing the performance and accuracy of machine vision systems across various sectors.

Strobe Type, Continuous Type in the Global Machine Vision Bar Lights Market:

In the Global Machine Vision Bar Lights Market, two primary types of lighting are utilized: Strobe Type and Continuous Type. Strobe Type lighting involves the use of short, intense bursts of light that are synchronized with the camera's exposure time. This type of lighting is particularly effective in high-speed applications where motion blur needs to be minimized. By providing a brief and powerful flash, strobe lights can freeze motion, allowing for clear and sharp images even when objects are moving rapidly. This makes them ideal for applications such as high-speed inspections, sorting, and quality control in industries like automotive and electronics. On the other hand, Continuous Type lighting provides a steady and constant source of illumination. This type of lighting is used in applications where consistent lighting conditions are required over a longer period. Continuous lighting is beneficial for processes that involve slower-moving objects or where the lighting needs to be maintained for extended durations, such as in assembly line inspections or detailed surface analysis. Both types of lighting have their unique advantages and are chosen based on the specific requirements of the application. The choice between strobe and continuous lighting depends on factors such as the speed of the process, the nature of the objects being inspected, and the desired image quality. In some cases, a combination of both types may be used to achieve optimal results. The Global Machine Vision Bar Lights Market continues to evolve, with manufacturers developing advanced lighting solutions that offer greater flexibility, efficiency, and performance. As industries increasingly rely on automation and machine vision technologies, the demand for both strobe and continuous lighting solutions is expected to grow. This growth is driven by the need for precise and reliable lighting in various applications, from high-speed manufacturing to detailed quality inspections. Overall, the choice between strobe and continuous lighting in the Global Machine Vision Bar Lights Market is influenced by the specific needs of the application, with each type offering distinct benefits that contribute to the effectiveness of machine vision systems.

Bright Field Lighting, Dark Field Lighting in the Global Machine Vision Bar Lights Market:

The Global Machine Vision Bar Lights Market finds significant usage in two primary lighting techniques: Bright Field Lighting and Dark Field Lighting. Bright Field Lighting is a technique where the light source is positioned in such a way that it illuminates the object directly, creating a bright and well-lit image. This method is particularly effective for highlighting surface features, textures, and colors of the object being inspected. It is commonly used in applications where the goal is to detect surface defects, measure dimensions, or identify color variations. Bright Field Lighting is widely used in industries such as electronics, automotive, and pharmaceuticals, where precise inspection and quality control are critical. On the other hand, Dark Field Lighting involves positioning the light source at a low angle relative to the object, causing the light to reflect off the surface at an angle. This technique is used to enhance the visibility of surface defects, scratches, or edges that may not be visible under direct lighting. Dark Field Lighting is particularly useful for inspecting reflective or transparent surfaces, where traditional lighting methods may not provide sufficient contrast. It is commonly used in applications such as glass inspection, semiconductor manufacturing, and metal surface analysis. Both Bright Field and Dark Field Lighting techniques have their unique advantages and are chosen based on the specific requirements of the inspection process. The choice between these techniques depends on factors such as the nature of the object being inspected, the type of defects being detected, and the desired level of detail in the image. In some cases, a combination of both techniques may be used to achieve comprehensive inspection results. The Global Machine Vision Bar Lights Market continues to innovate, with manufacturers developing advanced lighting solutions that offer greater flexibility and performance. As industries increasingly rely on machine vision technologies for quality control and automation, the demand for both Bright Field and Dark Field Lighting solutions is expected to grow. This growth is driven by the need for precise and reliable lighting in various applications, from high-speed manufacturing to detailed quality inspections. Overall, the choice between Bright Field and Dark Field Lighting in the Global Machine Vision Bar Lights Market is influenced by the specific needs of the application, with each technique offering distinct benefits that contribute to the effectiveness of machine vision systems.

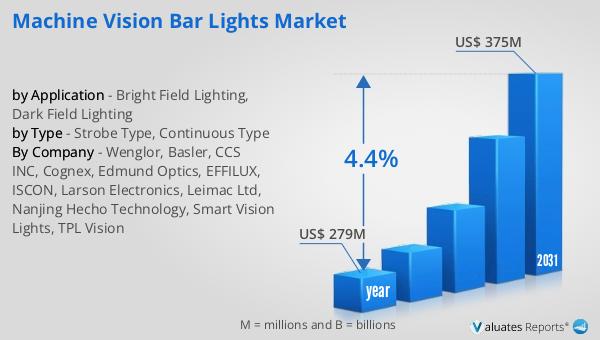

Global Machine Vision Bar Lights Market Outlook:

The global market for Machine Vision Bar Lights was valued at approximately $279 million in 2024, and it is anticipated to expand to a revised size of around $375 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.4% during the forecast period. This growth trajectory underscores the increasing demand for machine vision technologies across various industries. As businesses continue to automate their processes and enhance quality control measures, the need for reliable and efficient lighting solutions becomes paramount. Machine Vision Bar Lights play a crucial role in these systems by providing the necessary illumination for accurate image capture and analysis. The market's expansion is driven by advancements in technology, increased adoption of automation, and the growing emphasis on precision and efficiency in manufacturing and production processes. As industries such as automotive, electronics, and pharmaceuticals continue to evolve, the demand for machine vision systems, including bar lights, is expected to rise. This growth is further supported by the continuous innovation in lighting solutions, with manufacturers developing new products to meet the changing needs of their customers. Overall, the Global Machine Vision Bar Lights Market is poised for steady growth, driven by the increasing adoption of machine vision technologies and the ongoing advancements in lighting solutions.

| Report Metric | Details |

| Report Name | Machine Vision Bar Lights Market |

| Accounted market size in year | US$ 279 million |

| Forecasted market size in 2031 | US$ 375 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wenglor, Basler, CCS INC, Cognex, Edmund Optics, EFFILUX, ISCON, Larson Electronics, Leimac Ltd, Nanjing Hecho Technology, Smart Vision Lights, TPL Vision |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |