What is Global Agricultural Forging Customization Service Market?

The Global Agricultural Forging Customization Service Market is a specialized sector that focuses on providing tailored forging solutions for agricultural machinery and equipment. This market caters to the unique needs of the agricultural industry by offering customized forging services that enhance the durability, efficiency, and performance of agricultural tools and machinery. Forging is a manufacturing process that involves shaping metal using localized compressive forces, and in the context of agriculture, it is used to produce robust components that can withstand the demanding conditions of farming operations. The customization aspect of this market is crucial as it allows manufacturers to design and produce parts that meet specific requirements, ensuring compatibility and optimal performance in various agricultural applications. This market is driven by the increasing demand for high-quality, durable agricultural equipment that can improve productivity and reduce downtime. As the agricultural sector continues to evolve with advancements in technology and practices, the need for customized forging solutions is expected to grow, making this market an essential component of the global agricultural industry.

Open Die Process, Closed Die Process, Seamless Rolled Ring Process, Cold Forging Process in the Global Agricultural Forging Customization Service Market:

The Global Agricultural Forging Customization Service Market employs several forging processes to meet the diverse needs of the agricultural sector. The Open Die Process is one of the primary methods used, where metal is shaped by compressive forces between flat or simple contoured dies that do not enclose the workpiece. This process is ideal for producing large, simple-shaped components and is highly flexible, allowing for the creation of custom parts with varying dimensions. It is particularly useful for manufacturing large agricultural machinery parts that require high strength and durability. The Closed Die Process, on the other hand, involves shaping metal within a set of dies that enclose the workpiece, allowing for more complex shapes and precise dimensions. This process is suitable for producing smaller, intricate components that require high precision, such as gears and connectors used in agricultural equipment. The Seamless Rolled Ring Process is another critical method, where a pre-formed metal ring is rolled into a thinner, larger diameter ring. This process is used to manufacture components like bearings and flanges, which are essential for the smooth operation of agricultural machinery. The Cold Forging Process involves shaping metal at room temperature, resulting in parts with excellent surface finish and dimensional accuracy. This process is ideal for producing high-volume, small-sized components that require tight tolerances, such as fasteners and fittings used in agricultural equipment. Each of these processes offers unique advantages and is selected based on the specific requirements of the agricultural application, ensuring that the final product meets the desired performance and quality standards. The ability to customize these processes to produce tailored solutions is what sets the Global Agricultural Forging Customization Service Market apart, providing agricultural manufacturers with the flexibility and precision needed to enhance their equipment's performance and longevity.

Agriculture, Water Conservancy, Other in the Global Agricultural Forging Customization Service Market:

The Global Agricultural Forging Customization Service Market plays a vital role in various sectors, including agriculture, water conservancy, and other related fields. In agriculture, customized forging services are essential for producing high-quality components that enhance the performance and durability of farming equipment. This includes parts for tractors, plows, harvesters, and other machinery that are subjected to harsh working conditions. By providing tailored solutions, the market ensures that these components meet specific requirements, improving efficiency and reducing maintenance costs. In the water conservancy sector, forging customization services are used to produce components for irrigation systems, pumps, and other water management equipment. These components must withstand exposure to water and varying environmental conditions, making durability and precision crucial. Customized forging solutions ensure that these parts are designed to meet the specific needs of water conservancy projects, enhancing their reliability and lifespan. Additionally, the market serves other sectors that require robust and precise components, such as construction and mining. In these industries, customized forging services are used to produce parts for heavy machinery and equipment that must endure extreme conditions and heavy loads. The ability to tailor forging processes to produce components that meet the unique demands of each sector is what makes the Global Agricultural Forging Customization Service Market indispensable. By providing high-quality, customized solutions, the market supports the efficient and reliable operation of equipment across various industries, contributing to improved productivity and reduced operational costs.

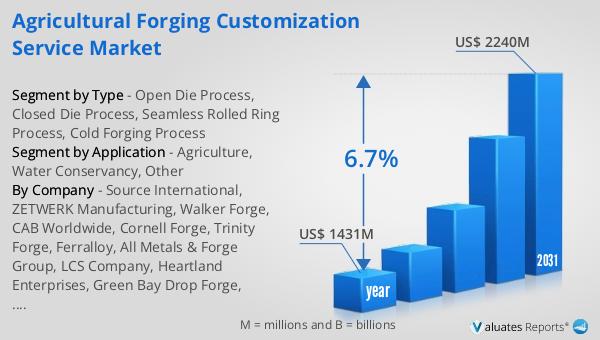

Global Agricultural Forging Customization Service Market Outlook:

In 2024, the Global Agricultural Forging Customization Service Market was valued at approximately $1,431 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated value of $2,240 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.7% during the forecast period. The market's expansion can be attributed to the increasing demand for customized forging solutions in the agricultural sector, driven by the need for high-quality, durable components that enhance the performance and efficiency of agricultural machinery. As the agricultural industry continues to evolve with advancements in technology and practices, the demand for tailored forging services is expected to rise, supporting the market's growth. The ability to provide customized solutions that meet the specific requirements of agricultural applications is a key factor driving the market's success. By offering high-quality, durable components that improve the performance and longevity of agricultural equipment, the Global Agricultural Forging Customization Service Market is poised for continued growth and success in the coming years.

| Report Metric | Details |

| Report Name | Agricultural Forging Customization Service Market |

| Accounted market size in year | US$ 1431 million |

| Forecasted market size in 2031 | US$ 2240 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Source International, ZETWERK Manufacturing, Walker Forge, CAB Worldwide, Cornell Forge, Trinity Forge, Ferralloy, All Metals & Forge Group, LCS Company, Heartland Enterprises, Green Bay Drop Forge, Dalton Consulting Group, MFI Global Manufacturing, VIP Machining, Queen City Forging |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |