What is Global Wall Plastering Machine Market?

The Global Wall Plastering Machine Market refers to the industry focused on the production, distribution, and utilization of machines designed to apply plaster to walls efficiently. These machines are a significant advancement in the construction sector, offering a faster and more consistent method of plastering compared to traditional manual techniques. Wall plastering machines are used in various construction projects, from residential buildings to large commercial structures, providing a smooth and even finish on walls. The market for these machines is driven by the increasing demand for automation in construction processes, which helps in reducing labor costs and time while enhancing the quality of work. With the construction industry continuously evolving, the adoption of wall plastering machines is expected to grow, as they cater to the need for speed and precision in modern building projects. These machines come in different types and sizes, catering to various project requirements, and are equipped with features that allow for easy operation and maintenance. As the construction industry expands globally, the wall plastering machine market is poised to witness significant growth, driven by technological advancements and the increasing focus on sustainable and efficient building practices.

Automatic, Manual in the Global Wall Plastering Machine Market:

In the Global Wall Plastering Machine Market, machines are broadly categorized into automatic and manual types, each serving distinct needs and preferences within the construction industry. Automatic wall plastering machines are designed to streamline the plastering process by minimizing human intervention. These machines are equipped with advanced technology that allows them to apply plaster evenly and efficiently across large wall surfaces. They are particularly beneficial in large-scale construction projects where time and labor efficiency are crucial. Automatic machines often come with features such as adjustable speed settings, easy-to-use control panels, and the ability to handle different types of plaster materials. They are designed to reduce the physical strain on workers and increase productivity by covering more area in less time compared to manual methods. On the other hand, manual wall plastering machines require more human involvement but offer greater control over the plastering process. These machines are typically more affordable and are preferred in smaller projects or where budget constraints are a concern. Manual machines allow operators to adjust the application technique according to the specific requirements of the project, providing a level of customization that automatic machines may not offer. Despite requiring more effort, manual machines are valued for their simplicity and the skill they allow workers to apply in their craft. Both automatic and manual wall plastering machines have their place in the market, with the choice between them often depending on the scale of the project, budget considerations, and the desired level of automation. As technology continues to advance, the line between automatic and manual machines may blur, with hybrid models offering the best of both worlds. These machines are expected to incorporate features that enhance efficiency while maintaining the flexibility and control that manual machines provide. The ongoing development in this market segment reflects the broader trends in the construction industry towards increased automation and efficiency, while still valuing the craftsmanship and adaptability that manual methods offer. As the demand for faster and more efficient construction methods grows, the Global Wall Plastering Machine Market will continue to evolve, offering solutions that meet the diverse needs of the industry.

Surface Decoration, Gap Repair, Others in the Global Wall Plastering Machine Market:

The usage of Global Wall Plastering Machines extends to various applications, including surface decoration, gap repair, and other specialized tasks. In surface decoration, these machines play a crucial role in achieving a smooth and aesthetically pleasing finish on walls. They ensure that the plaster is applied evenly, which is essential for creating a perfect base for further decorative elements such as paint or wallpaper. The precision and consistency offered by wall plastering machines make them ideal for projects where the visual appeal of the finished surface is a priority. In gap repair, wall plastering machines are used to fill and smooth out imperfections or gaps in walls. This application is particularly important in renovation projects where existing structures need to be updated or repaired. The machines allow for quick and efficient filling of gaps, ensuring that the repaired areas blend seamlessly with the rest of the wall. This not only improves the structural integrity of the building but also enhances its overall appearance. Beyond surface decoration and gap repair, wall plastering machines are used in a variety of other applications. They are employed in the construction of new buildings, where they help in applying the initial layers of plaster that form the foundation for further construction work. Additionally, these machines are used in specialized projects such as the creation of textured surfaces or the application of special plaster materials that require precise handling. The versatility of wall plastering machines makes them an invaluable tool in the construction industry, capable of adapting to a wide range of project requirements. As the demand for high-quality construction work continues to rise, the use of wall plastering machines in these various applications is expected to grow. Their ability to deliver consistent results, reduce labor costs, and increase efficiency makes them an essential component of modern construction practices.

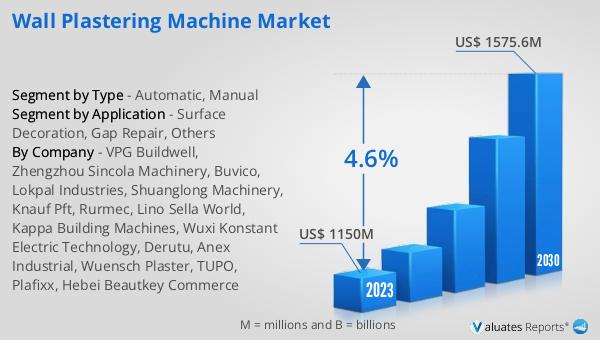

Global Wall Plastering Machine Market Outlook:

The global market for wall plastering machines was valued at approximately $1,253 million in 2024. It is anticipated to expand to a revised size of around $1,709 million by the year 2031, reflecting a compound annual growth rate (CAGR) of 4.6% over the forecast period. This growth trajectory highlights the increasing demand for wall plastering machines as the construction industry seeks more efficient and cost-effective solutions. The steady rise in market value underscores the importance of these machines in modern construction practices, where speed, precision, and quality are paramount. As the market continues to evolve, manufacturers are likely to focus on developing more advanced and versatile machines that cater to the diverse needs of the construction sector. This growth is driven by factors such as technological advancements, the need for automation, and the expansion of the construction industry globally. The projected increase in market size indicates a positive outlook for the wall plastering machine industry, as it adapts to meet the changing demands of the construction landscape. With the ongoing emphasis on sustainable and efficient building practices, the market for wall plastering machines is poised for continued growth and innovation.

| Report Metric | Details |

| Report Name | Wall Plastering Machine Market |

| Accounted market size in year | US$ 1253 million |

| Forecasted market size in 2031 | US$ 1709 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | VPG Buildwell, Zhengzhou Sincola Machinery, Buvico, Lokpal Industries, Shuanglong Machinery, Knauf Pft, Rurmec, Lino Sella World, Kappa Building Machines, Wuxi Konstant Electric Technology, Derutu, Anex Industrial, Wuensch Plaster, TUPO, Plafixx, Hebei Beautkey Commerce |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |