What is Global Vertical Submersible Slurry Pump Market?

The Global Vertical Submersible Slurry Pump Market refers to the industry focused on the production and distribution of vertical submersible slurry pumps. These pumps are specifically designed to handle slurry, a mixture of solid particles and liquid, which is often abrasive and corrosive. They are used in various industries to transport slurry from one location to another, especially in challenging environments where traditional pumps might fail. The vertical design allows these pumps to be submerged in the slurry, providing efficient and effective pumping action. This market is driven by the demand from industries such as mining, metallurgy, and environmental protection, where the handling of slurry is a critical part of operations. The market is characterized by technological advancements aimed at improving pump efficiency, durability, and energy consumption. Manufacturers are continually innovating to meet the specific needs of different industries, ensuring that the pumps can handle varying slurry compositions and operational conditions. As industries continue to expand and modernize, the demand for reliable and efficient slurry pumps is expected to grow, making this market a vital component of industrial operations worldwide.

V-Belt Drive, Elastic Coupling Drive in the Global Vertical Submersible Slurry Pump Market:

In the context of the Global Vertical Submersible Slurry Pump Market, V-Belt Drive and Elastic Coupling Drive are two prevalent methods used to transmit power from the motor to the pump. The V-Belt Drive system is a traditional method that uses a belt to connect the motor and the pump. This system is known for its simplicity and cost-effectiveness. The V-belt, made of rubber or synthetic materials, wraps around pulleys attached to the motor and pump shafts. As the motor rotates, the belt transfers the rotational motion to the pump, enabling it to operate. One of the main advantages of the V-Belt Drive is its ability to absorb shock loads and vibrations, which can prolong the life of the pump and motor. Additionally, it allows for some misalignment between the motor and pump, providing flexibility in installation. However, V-Belt Drives require regular maintenance, such as tension adjustments and belt replacements, to ensure optimal performance. On the other hand, the Elastic Coupling Drive is a more modern approach that uses an elastic element to connect the motor and pump shafts. This system is designed to accommodate misalignment and absorb vibrations, similar to the V-Belt Drive, but with enhanced efficiency and reduced maintenance requirements. The elastic coupling consists of a flexible material, often rubber or a polymer, that can deform under load, allowing for smooth power transmission even in the presence of misalignment. This flexibility reduces the stress on the motor and pump components, potentially extending their lifespan. Elastic Coupling Drives are particularly beneficial in applications where precise alignment is challenging or where the pump is subject to frequent start-stop cycles. They offer a quieter operation compared to V-Belt Drives, as the elastic element dampens noise and vibrations. In the Global Vertical Submersible Slurry Pump Market, the choice between V-Belt Drive and Elastic Coupling Drive depends on several factors, including the specific application requirements, cost considerations, and maintenance capabilities. While V-Belt Drives remain popular due to their simplicity and lower initial cost, Elastic Coupling Drives are gaining traction for their efficiency and reduced maintenance needs. As industries continue to seek ways to improve operational efficiency and reduce downtime, the demand for advanced drive systems like Elastic Coupling Drives is expected to increase. Both drive systems play a crucial role in ensuring the reliable and efficient operation of vertical submersible slurry pumps, which are essential for handling abrasive and corrosive slurries in various industrial applications.

Metallurgy Mining, Electric Power, Environmental Protection, Others in the Global Vertical Submersible Slurry Pump Market:

The Global Vertical Submersible Slurry Pump Market finds extensive usage across several industries, including metallurgy, mining, electric power, and environmental protection. In the metallurgy industry, these pumps are crucial for handling slurry generated during the processing of metals. The abrasive nature of the slurry, often containing metal particles and other solid materials, requires robust and durable pumps capable of withstanding harsh conditions. Vertical submersible slurry pumps are designed to operate efficiently in such environments, ensuring the smooth transportation of slurry and minimizing downtime. In the mining industry, these pumps are indispensable for transporting slurry from mining sites to processing facilities. The slurry in mining operations typically contains a mixture of water, minerals, and other solid particles, making it highly abrasive and challenging to handle. Vertical submersible slurry pumps are engineered to handle these demanding conditions, providing reliable performance and reducing the risk of equipment failure. Their ability to operate submerged in slurry makes them ideal for mining applications, where space and accessibility can be limited. In the electric power industry, vertical submersible slurry pumps are used in coal-fired power plants to transport ash slurry from the combustion process. The ash slurry, a byproduct of burning coal, is highly abrasive and requires specialized pumps to handle it effectively. These pumps ensure the efficient removal of ash slurry, preventing blockages and maintaining the smooth operation of power plants. Additionally, they are used in hydroelectric power plants to manage water and sediment mixtures, contributing to the overall efficiency of power generation. Environmental protection is another critical area where vertical submersible slurry pumps are utilized. These pumps play a vital role in wastewater treatment plants, where they are used to transport sludge and other waste materials. The ability to handle corrosive and abrasive slurries makes them ideal for treating industrial and municipal wastewater, ensuring the effective removal of contaminants and protecting the environment. Furthermore, they are used in dredging operations to remove sediment and debris from water bodies, contributing to environmental conservation efforts. In summary, the Global Vertical Submersible Slurry Pump Market serves a wide range of industries, each with unique requirements for handling slurry. The versatility and durability of these pumps make them essential for efficient and reliable operations in metallurgy, mining, electric power, and environmental protection. As industries continue to evolve and face new challenges, the demand for advanced slurry pump solutions is expected to grow, driving innovation and development in this market.

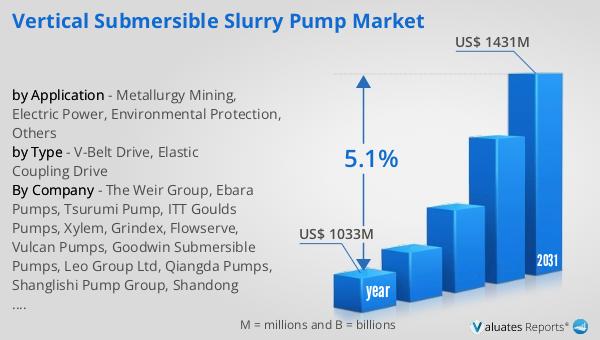

Global Vertical Submersible Slurry Pump Market Outlook:

The global market for Vertical Submersible Slurry Pumps was valued at approximately $1,033 million in 2024. It is anticipated to expand to a revised size of around $1,431 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth trajectory underscores the increasing demand for these pumps across various industries. The market's expansion can be attributed to several factors, including the rising need for efficient slurry handling solutions in sectors such as mining, metallurgy, and environmental protection. As industries continue to modernize and expand, the demand for reliable and durable slurry pumps is expected to rise, driving market growth. Additionally, technological advancements in pump design and materials are contributing to the market's development, offering improved efficiency and performance. The projected growth rate of 5.1% indicates a steady increase in market size, reflecting the ongoing importance of vertical submersible slurry pumps in industrial operations. As the market evolves, manufacturers are likely to focus on innovation and product development to meet the changing needs of their customers, ensuring the continued relevance and competitiveness of their offerings. Overall, the Global Vertical Submersible Slurry Pump Market is poised for significant growth, driven by the increasing demand for efficient and reliable slurry handling solutions across various industries.

| Report Metric | Details |

| Report Name | Vertical Submersible Slurry Pump Market |

| Accounted market size in year | US$ 1033 million |

| Forecasted market size in 2031 | US$ 1431 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | The Weir Group, Ebara Pumps, Tsurumi Pump, ITT Goulds Pumps, Xylem, Grindex, Flowserve, Vulcan Pumps, Goodwin Submersible Pumps, Leo Group Ltd, Qiangda Pumps, Shanglishi Pump Group, Shandong Shuanggong Pump Technology, Jiangsu Meifeng Pump Industry, Hebei Delin Machinery, Shandong Boshan Water Pump Equipment Factory, Hebei Gongqiang Pump, Hebei Chenglin Water Pump Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |