What is Global Vehicle Durability Testing Market?

The Global Vehicle Durability Testing Market is a specialized segment within the automotive industry that focuses on evaluating the longevity and robustness of vehicles under various conditions. This market encompasses a range of testing services and equipment designed to assess how vehicles and their components withstand wear and tear over time. Durability testing is crucial for manufacturers to ensure that their vehicles meet safety standards, perform reliably, and maintain quality over their lifespan. The market includes testing for passenger cars, commercial vehicles, and other types of vehicles, using both physical and virtual testing methods. With advancements in technology, the market has seen a shift towards more sophisticated testing techniques, including the use of simulation and data analytics. This allows manufacturers to predict potential failures and improve vehicle design before mass production. As consumer expectations for vehicle reliability and performance continue to rise, the demand for comprehensive durability testing is expected to grow, driving innovation and expansion in this market.

Vehicle Durability Testing, Parts Durability Testing in the Global Vehicle Durability Testing Market:

Vehicle Durability Testing is a critical process in the automotive industry, aimed at ensuring that vehicles can withstand the rigors of everyday use and extreme conditions. This testing involves subjecting vehicles to a series of controlled tests that simulate real-world driving conditions, such as rough terrains, varying weather conditions, and long-distance travel. The primary goal is to identify potential weaknesses in vehicle design and materials that could lead to premature failure or safety issues. Parts Durability Testing, a subset of vehicle durability testing, focuses specifically on individual components such as engines, transmissions, suspensions, and electronic systems. Each part is tested for its ability to endure stress, temperature fluctuations, and other environmental factors. This testing is essential for manufacturers to guarantee that each component meets quality standards and contributes to the overall durability of the vehicle. In the Global Vehicle Durability Testing Market, advancements in technology have led to more precise and efficient testing methods. For instance, the use of computer simulations allows engineers to model and predict how a vehicle or part will perform under various conditions without the need for physical prototypes. This not only speeds up the testing process but also reduces costs. Additionally, the integration of data analytics enables manufacturers to gather and analyze vast amounts of data from tests, providing insights into potential improvements in vehicle design and manufacturing processes. The market is also seeing a trend towards more environmentally friendly testing practices, with a focus on reducing emissions and energy consumption during testing procedures. As the automotive industry continues to evolve, the importance of vehicle and parts durability testing remains paramount. Manufacturers are under increasing pressure to produce vehicles that are not only safe and reliable but also meet the growing demands for sustainability and efficiency. This has led to a greater emphasis on testing and validation throughout the vehicle development process. In conclusion, Vehicle Durability Testing and Parts Durability Testing are integral components of the Global Vehicle Durability Testing Market. They play a vital role in ensuring that vehicles meet the highest standards of quality and performance, ultimately leading to safer and more reliable vehicles for consumers.

R&D Stage, Production Stage, Others in the Global Vehicle Durability Testing Market:

The Global Vehicle Durability Testing Market plays a crucial role in various stages of vehicle development, including the R&D stage, production stage, and other areas. During the R&D stage, durability testing is used to evaluate new vehicle designs and technologies before they are brought to market. This involves testing prototypes under simulated real-world conditions to identify potential issues and make necessary improvements. By conducting thorough durability testing during this stage, manufacturers can ensure that their vehicles meet safety and performance standards, reducing the risk of costly recalls or failures after production. In the production stage, durability testing is used to verify that vehicles and their components meet quality standards before they are released to consumers. This involves testing a sample of vehicles from the production line to ensure consistency and reliability. By identifying and addressing any issues during this stage, manufacturers can maintain high levels of quality control and customer satisfaction. Additionally, durability testing in the production stage helps manufacturers comply with regulatory requirements and industry standards, ensuring that their vehicles are safe and reliable for consumers. Beyond the R&D and production stages, the Global Vehicle Durability Testing Market also plays a role in other areas such as aftermarket testing and certification. Aftermarket testing involves evaluating replacement parts and accessories to ensure they meet the same durability and performance standards as original equipment. This is important for maintaining vehicle safety and reliability, as well as protecting the reputation of manufacturers and suppliers. Certification testing, on the other hand, involves verifying that vehicles and their components meet specific regulatory requirements and industry standards. This is essential for manufacturers to gain market access and ensure compliance with safety and environmental regulations. Overall, the Global Vehicle Durability Testing Market is an essential component of the automotive industry, providing valuable insights and data that help manufacturers improve vehicle design, quality, and performance. By investing in comprehensive durability testing, manufacturers can ensure that their vehicles meet the highest standards of safety and reliability, ultimately leading to greater customer satisfaction and brand loyalty.

Global Vehicle Durability Testing Market Outlook:

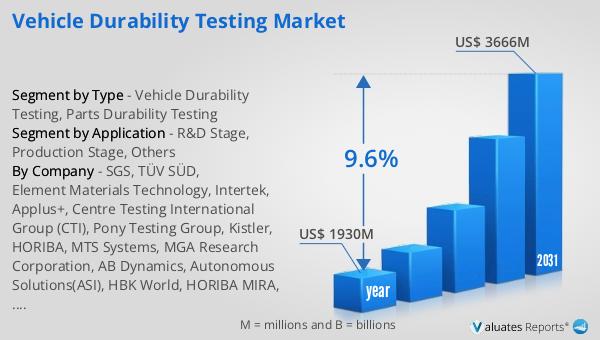

In 2024, the global market for Vehicle Durability Testing was valued at approximately $1.93 billion. Looking ahead, it is anticipated that this market will expand significantly, reaching an estimated value of $3.67 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 9.6% over the forecast period. This robust growth can be attributed to several factors, including the increasing demand for reliable and high-performance vehicles, advancements in testing technologies, and the growing emphasis on safety and quality standards within the automotive industry. As consumer expectations continue to rise, manufacturers are investing more in durability testing to ensure their vehicles meet these demands. Additionally, the shift towards electric and autonomous vehicles is driving the need for more comprehensive testing solutions, further fueling market growth. The expansion of the Vehicle Durability Testing Market is also supported by the increasing complexity of modern vehicles, which require more sophisticated testing methods to evaluate their performance and reliability. As a result, the market is expected to continue its upward trajectory, providing opportunities for innovation and development in testing technologies and methodologies.

| Report Metric | Details |

| Report Name | Vehicle Durability Testing Market |

| Accounted market size in year | US$ 1930 million |

| Forecasted market size in 2031 | US$ 3666 million |

| CAGR | 9.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | SGS, TÜV SÜD, Element Materials Technology, Intertek, Applus+, Centre Testing International Group (CTI), Pony Testing Group, Kistler, HORIBA, MTS Systems, MGA Research Corporation, AB Dynamics, Autonomous Solutions(ASI), HBK World, HORIBA MIRA, NATC, ATDS Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |