What is Global Ultrasonic Welder Sales Market?

The Global Ultrasonic Welder Sales Market refers to the worldwide industry involved in the production, distribution, and sale of ultrasonic welding machines. These machines use high-frequency ultrasonic acoustic vibrations to create solid-state welds between materials, typically plastics or metals, without the need for additional adhesives or soldering materials. This technology is highly valued for its precision, speed, and ability to produce strong, clean welds, making it a popular choice in various industries such as automotive, electronics, medical devices, and packaging. The market encompasses a wide range of ultrasonic welding equipment, from small, handheld devices to large, automated systems designed for industrial use. The growth of this market is driven by increasing demand for lightweight and durable materials, advancements in manufacturing technologies, and the need for efficient and environmentally friendly production processes. As industries continue to innovate and seek more efficient manufacturing solutions, the Global Ultrasonic Welder Sales Market is expected to expand, offering new opportunities for manufacturers and suppliers worldwide.

in the Global Ultrasonic Welder Sales Market:

In the Global Ultrasonic Welder Sales Market, various types of ultrasonic welders are utilized by customers based on their specific needs and applications. One of the most common types is the plastic ultrasonic welder, which dominates the market with a significant share. These welders are specifically designed to join thermoplastic materials, making them ideal for industries that require precise and reliable bonding of plastic components. The plastic ultrasonic welder is favored for its ability to create strong, clean welds without the need for additional adhesives or fasteners, reducing production costs and improving product quality. Another type of ultrasonic welder is the metal ultrasonic welder, which is used for joining thin sheets of metal or wire. This type of welder is particularly useful in the electronics and automotive industries, where it is essential to create strong, conductive bonds between metal components. Metal ultrasonic welders are valued for their ability to produce high-quality welds without the need for additional materials, making them a cost-effective and efficient solution for manufacturers. In addition to plastic and metal ultrasonic welders, there are also specialized ultrasonic welding machines designed for specific applications. For example, ultrasonic spot welders are used for creating small, localized welds in materials such as textiles or thin films. These machines are often used in the production of medical devices, where precision and cleanliness are critical. Another specialized type is the ultrasonic tube sealer, which is used to seal the ends of plastic or metal tubes, commonly found in the packaging industry. This type of welder is valued for its ability to create airtight seals quickly and efficiently, ensuring the integrity of the packaged product. The Global Ultrasonic Welder Sales Market also includes automated ultrasonic welding systems, which are designed for high-volume production environments. These systems are equipped with advanced features such as robotic arms, programmable controls, and real-time monitoring capabilities, allowing manufacturers to achieve consistent, high-quality welds with minimal human intervention. Automated ultrasonic welding systems are particularly popular in the automotive and electronics industries, where they are used to produce large quantities of components with precision and efficiency. Overall, the Global Ultrasonic Welder Sales Market offers a wide range of welding solutions to meet the diverse needs of customers across various industries. Whether it is a simple handheld device for small-scale applications or a complex automated system for high-volume production, ultrasonic welders provide a reliable and efficient solution for joining materials. As technology continues to advance and industries seek more efficient manufacturing processes, the demand for ultrasonic welding equipment is expected to grow, driving innovation and expansion in the market.

in the Global Ultrasonic Welder Sales Market:

The Global Ultrasonic Welder Sales Market serves a wide range of applications across various industries, each benefiting from the unique advantages of ultrasonic welding technology. In the automotive industry, ultrasonic welders are used to join plastic components such as dashboards, door panels, and interior trim. The ability to create strong, durable welds without the need for additional adhesives or fasteners makes ultrasonic welding an ideal solution for automotive manufacturers looking to reduce weight and improve fuel efficiency. Additionally, ultrasonic welding is used to join electrical components and wiring harnesses, ensuring reliable connections and reducing the risk of electrical failures. In the electronics industry, ultrasonic welders are used to assemble small, delicate components such as circuit boards, sensors, and connectors. The precision and speed of ultrasonic welding make it an ideal solution for manufacturers looking to produce high-quality electronic devices with minimal risk of damage to sensitive components. Ultrasonic welding is also used to create strong, conductive bonds between metal components, ensuring reliable electrical connections in devices such as smartphones, tablets, and laptops. The medical device industry also relies heavily on ultrasonic welding technology, particularly for the production of disposable medical products such as IV bags, catheters, and surgical instruments. The ability to create clean, sterile welds without the need for additional adhesives or solvents makes ultrasonic welding an ideal solution for manufacturers looking to produce safe and reliable medical devices. Additionally, ultrasonic welding is used to assemble complex medical devices such as pacemakers and hearing aids, where precision and reliability are critical. In the packaging industry, ultrasonic welders are used to seal plastic and metal containers, ensuring the integrity and safety of packaged products. The ability to create airtight seals quickly and efficiently makes ultrasonic welding an ideal solution for manufacturers looking to improve production efficiency and reduce waste. Additionally, ultrasonic welding is used to create tamper-evident seals on packaging, providing an added layer of security for consumers. Overall, the Global Ultrasonic Welder Sales Market serves a diverse range of applications across various industries, each benefiting from the unique advantages of ultrasonic welding technology. Whether it is joining plastic components in the automotive industry, assembling delicate electronic devices, or producing safe and reliable medical products, ultrasonic welding provides a reliable and efficient solution for manufacturers worldwide. As industries continue to innovate and seek more efficient manufacturing processes, the demand for ultrasonic welding equipment is expected to grow, driving further expansion and innovation in the market.

Global Ultrasonic Welder Sales Market Outlook:

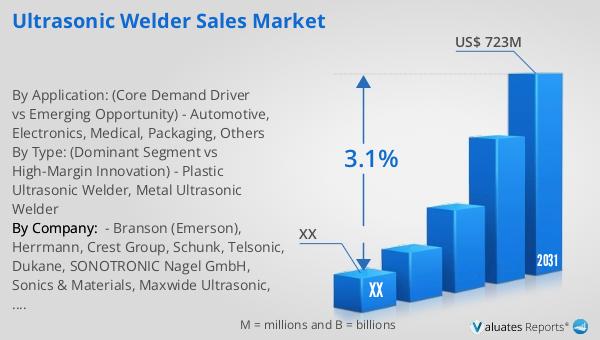

In 2024, the global market for ultrasonic welders was valued at approximately $585 million. By 2031, it is anticipated to grow to a revised size of around $723 million, reflecting a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2025 to 2031. The market is characterized by a significant concentration of production, with the top five manufacturers collectively holding over 40% of the market share. Among the various products available, plastic ultrasonic welders represent the largest segment, accounting for about 90% of the market. This dominance is largely due to the widespread use of plastic ultrasonic welders in industries such as automotive, electronics, and medical devices, where the ability to create strong, clean welds without additional adhesives or fasteners is highly valued. The growth of the ultrasonic welder market is driven by increasing demand for lightweight and durable materials, advancements in manufacturing technologies, and the need for efficient and environmentally friendly production processes. As industries continue to innovate and seek more efficient manufacturing solutions, the Global Ultrasonic Welder Sales Market is expected to expand, offering new opportunities for manufacturers and suppliers worldwide.

| Report Metric | Details |

| Report Name | Ultrasonic Welder Sales Market |

| Forecasted market size in 2031 | US$ 723 million |

| CAGR | 3.1% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Branson (Emerson), Herrmann, Crest Group, Schunk, Telsonic, Dukane, SONOTRONIC Nagel GmbH, Sonics & Materials, Maxwide Ultrasonic, SEDECO, Kepu, K-Sonic, Kormax System, Xin Dongli, Nippon Avionics, Ever Ultrasonic, Hornwell, Sonobond, Ultrasonic Engineering Co.,Ltd, Shanghai Chenfeng, Dongho, Topstar |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |