What is Global Ultra Fine Aluminium Hydroxide Sales Market?

The Global Ultra Fine Aluminium Hydroxide Sales Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of ultra-fine aluminium hydroxide. This compound is a white, crystalline powder known for its flame-retardant properties, making it a valuable component in various industrial applications. The market is driven by the increasing demand for flame retardants in industries such as plastics, rubber, and coatings. Ultra-fine aluminium hydroxide is preferred due to its ability to enhance the fire resistance of materials without compromising their mechanical properties. Additionally, it is used as a filler in the production of paper, adhesives, and sealants, contributing to its widespread adoption. The market is characterized by a competitive landscape with several key players striving to expand their product portfolios and geographical reach. Technological advancements and innovations in production processes are also influencing market dynamics, enabling manufacturers to offer high-quality products that meet stringent regulatory standards. As industries continue to prioritize safety and sustainability, the demand for ultra-fine aluminium hydroxide is expected to grow, further solidifying its position in the global market.

in the Global Ultra Fine Aluminium Hydroxide Sales Market:

In the Global Ultra Fine Aluminium Hydroxide Sales Market, various types of ultra-fine aluminium hydroxide are utilized by different customers, each catering to specific needs and applications. One of the most common types is the 11.5 μm grade, which holds the largest market share due to its versatility and effectiveness in a wide range of applications. This particular grade is highly sought after in the plastics industry, where it is used as a flame retardant additive. Its fine particle size allows for easy dispersion within polymer matrices, enhancing the fire resistance of the final product without affecting its physical properties. Another type is the 1.0 μm grade, which is often used in high-performance applications requiring superior flame retardancy and thermal stability. This grade is particularly popular in the electronics industry, where it is used in the production of circuit boards and other components that require stringent fire safety standards. Additionally, the 1.0 μm grade is used in the production of advanced coatings and adhesives, where its fine particle size contributes to improved surface finish and adhesion properties. The market also offers ultra-fine aluminium hydroxide in various other particle sizes, each tailored to meet specific customer requirements. For instance, the 3.0 μm grade is commonly used in the rubber industry, where it serves as a flame retardant and smoke suppressant in the production of cables, hoses, and other rubber products. Its ability to enhance the fire resistance of rubber compounds while maintaining their flexibility and durability makes it a preferred choice among manufacturers. Furthermore, the 3.0 μm grade is used in the production of sealants and adhesives, where its fine particle size ensures uniform dispersion and improved performance. In addition to these standard grades, the market also offers customized ultra-fine aluminium hydroxide products, designed to meet the unique needs of specific applications. These customized products are often developed in collaboration with customers, ensuring that they meet the desired performance criteria and regulatory requirements. The availability of a wide range of ultra-fine aluminium hydroxide types allows customers to select the most suitable product for their specific applications, ensuring optimal performance and cost-effectiveness. As industries continue to evolve and demand more advanced materials, the development of new and innovative ultra-fine aluminium hydroxide products is expected to drive further growth in the market.

in the Global Ultra Fine Aluminium Hydroxide Sales Market:

Ultra-fine aluminium hydroxide finds applications across a diverse range of industries, each leveraging its unique properties to enhance product performance and safety. One of the primary applications is in the plastics industry, where it is used as a flame retardant additive. Its ability to improve the fire resistance of plastic materials without compromising their mechanical properties makes it an essential component in the production of electrical enclosures, automotive parts, and construction materials. The compound's fine particle size ensures uniform dispersion within polymer matrices, resulting in enhanced flame retardancy and reduced smoke emission. In the rubber industry, ultra-fine aluminium hydroxide is used as a flame retardant and smoke suppressant in the production of cables, hoses, and other rubber products. Its incorporation into rubber compounds enhances their fire resistance while maintaining flexibility and durability, making it a preferred choice for manufacturers seeking to meet stringent fire safety standards. Additionally, the compound is used in the production of sealants and adhesives, where its fine particle size ensures uniform dispersion and improved performance. The electronics industry also benefits from the use of ultra-fine aluminium hydroxide, particularly in the production of circuit boards and other components that require high levels of fire safety. Its superior flame retardancy and thermal stability make it an ideal choice for applications where safety and reliability are paramount. Furthermore, the compound is used in the production of advanced coatings, where its fine particle size contributes to improved surface finish and adhesion properties. In the paper industry, ultra-fine aluminium hydroxide is used as a filler to improve the brightness, opacity, and printability of paper products. Its ability to enhance the physical properties of paper while maintaining its recyclability makes it a valuable component in the production of high-quality paper products. Additionally, the compound is used in the production of adhesives and sealants, where its fine particle size ensures uniform dispersion and improved performance. As industries continue to prioritize safety and sustainability, the demand for ultra-fine aluminium hydroxide is expected to grow, further solidifying its position in the global market.

Global Ultra Fine Aluminium Hydroxide Sales Market Outlook:

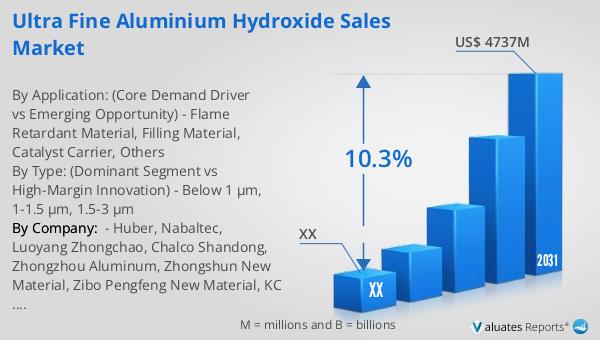

The global market for Ultra Fine Aluminium Hydroxide was valued at approximately $2,407 million in 2024, and it is projected to grow significantly, reaching an estimated $4,737 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 10.3% during the forecast period from 2025 to 2031. The market is characterized by a competitive landscape, with the top five players collectively holding around 26% of the market share. North America stands as the largest market for Ultra Fine Aluminium Hydroxide, accounting for about 36% of the global share. Following North America, China and Europe are also significant markets, holding approximately 27% and 26% of the market share, respectively. In terms of product types, the 11.5 μm segment is the largest, representing about 44% of the market. This segment's dominance is attributed to its versatility and effectiveness in a wide range of applications, particularly in industries that require enhanced fire resistance and safety standards. The market's growth is driven by increasing demand across various industries, including plastics, rubber, electronics, and coatings, where Ultra Fine Aluminium Hydroxide is used to improve product performance and safety. As industries continue to prioritize safety and sustainability, the demand for Ultra Fine Aluminium Hydroxide is expected to grow, further solidifying its position in the global market.

| Report Metric | Details |

| Report Name | Ultra Fine Aluminium Hydroxide Sales Market |

| Forecasted market size in 2031 | US$ 4737 million |

| CAGR | 10.3% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Huber, Nabaltec, Luoyang Zhongchao, Chalco Shandong, Zhongzhou Aluminum, Zhongshun New Material, Zibo Pengfeng New Material, KC Corp, Showa Denko, MAL Magyar Aluminium, Hubei Zhenhua Chemical, Zibo Jianzhan Technology, Shandong Taixing New Material, Shandong Linjia New Material, Sumitomo, Nippon Light Metal, R.J. Marshall, Seibou Chemical Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |