What is Global Topcoats for Aerospace Coatings Market?

The Global Topcoats for Aerospace Coatings Market is a specialized segment within the aerospace industry that focuses on the application of protective and decorative coatings on aircraft surfaces. These topcoats are crucial for enhancing the durability, appearance, and performance of aircraft by providing a protective layer against environmental factors such as UV radiation, corrosion, and extreme temperatures. The market encompasses a variety of products designed to meet the stringent requirements of the aerospace sector, including resistance to wear and tear, chemical exposure, and weathering. As the aerospace industry continues to expand, driven by increasing air travel demand and advancements in aircraft technology, the need for high-performance topcoats is also on the rise. These coatings not only contribute to the longevity and safety of aircraft but also play a role in reducing maintenance costs and improving fuel efficiency by minimizing drag. The market is characterized by continuous innovation, with manufacturers investing in research and development to create coatings that are more environmentally friendly and efficient. Overall, the Global Topcoats for Aerospace Coatings Market is a dynamic and essential component of the aerospace industry, supporting the sector's growth and technological advancements.

Solvent-Based Coating, Powder Coating, Others in the Global Topcoats for Aerospace Coatings Market:

Solvent-based coatings, powder coatings, and other types of coatings are integral to the Global Topcoats for Aerospace Coatings Market, each offering unique properties and benefits tailored to specific aerospace applications. Solvent-based coatings are traditional coatings that use organic solvents as a medium to dissolve the resin, pigments, and additives. These coatings are known for their excellent adhesion, durability, and smooth finish, making them a popular choice for aerospace applications where high performance is critical. They provide a robust protective layer that can withstand harsh environmental conditions, including exposure to chemicals, UV radiation, and extreme temperatures. However, the use of organic solvents raises environmental concerns due to the emission of volatile organic compounds (VOCs), prompting the industry to seek more sustainable alternatives. Powder coatings, on the other hand, are a more environmentally friendly option as they do not contain solvents and therefore emit negligible VOCs. These coatings are applied as a dry powder and then cured under heat to form a hard, durable finish. Powder coatings offer excellent resistance to corrosion, chipping, and fading, making them ideal for aerospace applications where long-lasting protection is essential. They also provide a uniform finish and are available in a wide range of colors and textures, allowing for aesthetic customization. The application process of powder coatings is efficient and results in minimal waste, as any overspray can be collected and reused. This not only reduces environmental impact but also lowers production costs, making powder coatings an attractive option for manufacturers. In addition to solvent-based and powder coatings, the Global Topcoats for Aerospace Coatings Market includes other types of coatings such as water-based coatings and UV-curable coatings. Water-based coatings use water as a solvent, significantly reducing VOC emissions and offering a more environmentally friendly alternative to traditional solvent-based coatings. These coatings provide good adhesion, flexibility, and resistance to weathering, making them suitable for various aerospace applications. UV-curable coatings, meanwhile, are cured using ultraviolet light, allowing for rapid curing times and energy savings. These coatings offer excellent hardness, chemical resistance, and clarity, making them ideal for applications where quick turnaround times and high performance are required. The choice of coating type depends on several factors, including the specific requirements of the aerospace application, environmental regulations, and cost considerations. Manufacturers in the aerospace industry are increasingly adopting more sustainable coating solutions to comply with stringent environmental regulations and meet the growing demand for eco-friendly products. This shift towards greener alternatives is driving innovation in the market, with companies investing in research and development to create coatings that offer superior performance while minimizing environmental impact. As the aerospace industry continues to evolve, the demand for high-performance, sustainable topcoats is expected to grow, shaping the future of the Global Topcoats for Aerospace Coatings Market.

Civil Aviation, Military Aviation in the Global Topcoats for Aerospace Coatings Market:

The usage of Global Topcoats for Aerospace Coatings Market in civil aviation and military aviation is pivotal, as these coatings play a crucial role in ensuring the safety, performance, and longevity of aircraft. In civil aviation, topcoats are applied to commercial aircraft to protect them from the harsh environmental conditions they encounter during flight. These coatings provide a barrier against UV radiation, corrosion, and extreme temperatures, which can cause significant wear and tear on the aircraft's exterior surfaces. By enhancing the durability of the aircraft, topcoats help reduce maintenance costs and downtime, ensuring that airlines can operate efficiently and safely. Additionally, topcoats contribute to the aesthetic appeal of commercial aircraft, allowing airlines to maintain their brand image with vibrant and long-lasting colors. In military aviation, the requirements for topcoats are even more stringent due to the demanding conditions that military aircraft often face. These coatings must provide superior protection against corrosion, abrasion, and chemical exposure, as military aircraft are frequently exposed to harsh environments and aggressive substances. Topcoats used in military aviation are designed to withstand extreme temperatures and provide camouflage capabilities, which are essential for stealth operations. The durability and performance of these coatings are critical for maintaining the operational readiness and effectiveness of military aircraft, as any failure in the coating system can compromise the aircraft's performance and safety. Moreover, the use of advanced topcoats in both civil and military aviation can contribute to improved fuel efficiency by reducing drag. Smooth and well-maintained surfaces minimize air resistance, allowing aircraft to operate more efficiently and consume less fuel. This not only reduces operational costs but also supports environmental sustainability by lowering carbon emissions. As the aerospace industry continues to prioritize sustainability, the development and adoption of eco-friendly topcoats are becoming increasingly important. Overall, the Global Topcoats for Aerospace Coatings Market plays a vital role in supporting the aerospace industry by providing high-performance coatings that enhance the safety, efficiency, and longevity of aircraft. Whether in civil or military aviation, these coatings are essential for maintaining the integrity and performance of aircraft, ensuring that they can operate safely and effectively in a wide range of conditions. As the demand for air travel continues to grow and technological advancements drive innovation in the aerospace sector, the importance of high-quality topcoats will only increase, making them a critical component of the industry's future.

Global Topcoats for Aerospace Coatings Market Outlook:

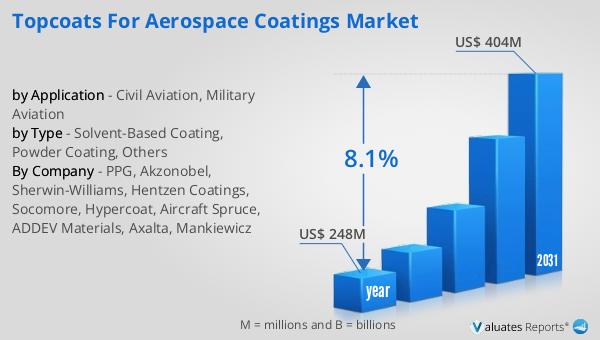

In 2024, the global market for Topcoats for Aerospace Coatings was valued at approximately $248 million. This market is anticipated to experience significant growth, reaching an estimated size of $404 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.1% over the forecast period. The increasing demand for high-performance coatings in the aerospace industry is a key driver of this growth, as these coatings are essential for enhancing the durability, safety, and efficiency of aircraft. The market's expansion is also supported by advancements in coating technologies and the growing emphasis on sustainability, with manufacturers investing in the development of eco-friendly and efficient coating solutions. As the aerospace industry continues to evolve, driven by rising air travel demand and technological innovations, the need for high-quality topcoats is expected to grow, further propelling the market's expansion. The projected growth of the Global Topcoats for Aerospace Coatings Market underscores the importance of these coatings in supporting the aerospace sector's development and addressing the industry's evolving needs.

| Report Metric | Details |

| Report Name | Topcoats for Aerospace Coatings Market |

| Accounted market size in year | US$ 248 million |

| Forecasted market size in 2031 | US$ 404 million |

| CAGR | 8.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PPG, Akzonobel, Sherwin-Williams, Hentzen Coatings, Socomore, Hypercoat, Aircraft Spruce, ADDEV Materials, Axalta, Mankiewicz |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |