What is Global Dental 3D Printing Software Market?

The Global Dental 3D Printing Software Market is a rapidly evolving segment within the broader dental industry, driven by technological advancements and the increasing demand for precision in dental care. This market encompasses a range of software solutions designed to facilitate the 3D printing of dental products, such as crowns, bridges, dentures, and orthodontic appliances. These software solutions are integral to the digital workflow in dental practices and laboratories, enabling the design, simulation, and production of dental components with high accuracy and efficiency. The market is characterized by a diverse array of software types, each serving a specific function in the 3D printing process. As dental professionals increasingly adopt digital technologies, the demand for sophisticated 3D printing software continues to grow, offering significant opportunities for innovation and development in this field. The integration of 3D printing technology in dentistry not only enhances the quality of dental care but also reduces the time and cost associated with traditional manufacturing methods. As a result, the Global Dental 3D Printing Software Market is poised for substantial growth, driven by the need for customized, patient-specific dental solutions.

3D Designing Software, Data Preparation Software, Simulation Software, Machine Control Software, Others in the Global Dental 3D Printing Software Market:

3D Designing Software is a crucial component of the Global Dental 3D Printing Software Market, providing the tools necessary for creating detailed digital models of dental structures. This software allows dental professionals to design custom dental appliances with precision, ensuring a perfect fit for each patient. By using advanced algorithms and user-friendly interfaces, 3D designing software simplifies the complex process of dental modeling, making it accessible to a wide range of users. Data Preparation Software, on the other hand, focuses on optimizing the digital models for 3D printing. It ensures that the designs are compatible with the printing hardware, adjusting parameters such as resolution and layer thickness to achieve the best possible results. This software is essential for minimizing errors and ensuring the structural integrity of the printed dental products. Simulation Software plays a vital role in the pre-production phase, allowing dental professionals to visualize and test the designs before printing. By simulating the physical properties and behavior of the dental appliances, this software helps identify potential issues and make necessary adjustments, reducing the risk of costly reprints. Machine Control Software is responsible for managing the 3D printing hardware, translating the digital designs into physical objects. It controls the movement of the printer's components, ensuring precise execution of the design specifications. This software is critical for maintaining the quality and consistency of the printed products. Lastly, the category of "Others" includes various auxiliary software solutions that support the overall 3D printing process. These may include software for post-processing, quality control, and workflow management, each contributing to the efficiency and effectiveness of the dental 3D printing ecosystem. Together, these software types form a comprehensive suite of tools that empower dental professionals to harness the full potential of 3D printing technology, delivering high-quality, customized dental solutions to patients worldwide.

Orthodontic Appliance Manufacturer, Laboratory, Hospitals and Dental Clinics, Others in the Global Dental 3D Printing Software Market:

The Global Dental 3D Printing Software Market finds extensive application across various sectors, including orthodontic appliance manufacturers, laboratories, hospitals, and dental clinics. Orthodontic appliance manufacturers utilize 3D printing software to design and produce custom orthodontic devices, such as braces and aligners, tailored to the unique dental anatomy of each patient. This technology enables manufacturers to create highly precise and effective appliances, improving patient outcomes and satisfaction. In dental laboratories, 3D printing software streamlines the production of dental prosthetics, such as crowns, bridges, and dentures. By automating the design and manufacturing process, laboratories can increase their productivity and reduce turnaround times, delivering high-quality products to dental professionals more efficiently. Hospitals and dental clinics also benefit from the integration of 3D printing software, as it allows for the rapid production of dental components on-site. This capability is particularly valuable in emergency situations, where time is of the essence, and traditional manufacturing methods may be too slow. Additionally, the use of 3D printing software in clinics enhances the patient experience by enabling same-day service for certain dental procedures. Beyond these primary applications, the Global Dental 3D Printing Software Market also serves other areas, such as academic institutions and research organizations. These entities leverage 3D printing technology for educational purposes, training the next generation of dental professionals in the latest digital techniques. Research organizations, on the other hand, use 3D printing software to explore new materials and methods, driving innovation and advancement in the field of dentistry. Overall, the widespread adoption of 3D printing software across these sectors underscores its transformative impact on the dental industry, offering significant benefits in terms of efficiency, precision, and patient care.

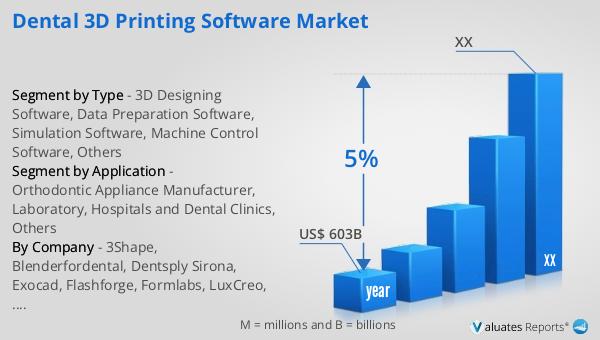

Global Dental 3D Printing Software Market Outlook:

Based on our analysis, the global market for medical devices is projected to reach approximately $603 billion in 2023. This substantial market size reflects the growing demand for advanced medical technologies and devices across various healthcare sectors. Over the next six years, the market is expected to expand at a compound annual growth rate (CAGR) of 5%. This steady growth trajectory indicates a robust and resilient market, driven by factors such as technological advancements, increasing healthcare expenditure, and the rising prevalence of chronic diseases. The medical device industry encompasses a wide range of products, from diagnostic equipment and surgical instruments to implantable devices and monitoring systems. As healthcare providers continue to seek innovative solutions to improve patient outcomes and operational efficiency, the demand for cutting-edge medical devices is likely to remain strong. Furthermore, the ongoing shift towards personalized medicine and minimally invasive procedures is expected to fuel the development and adoption of new medical technologies. In this dynamic and competitive landscape, companies operating in the medical device market must continuously innovate and adapt to changing market conditions to maintain their competitive edge. Overall, the global medical device market presents significant opportunities for growth and innovation, offering promising prospects for industry stakeholders in the coming years.

| Report Metric | Details |

| Report Name | Dental 3D Printing Software Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3Shape, Blenderfordental, Dentsply Sirona, Exocad, Flashforge, Formlabs, LuxCreo, Materialise Magics, Mogassam, Proto3000 Inc, SprintRay Inc., Stratasys, Voxel Dental, Zortrax |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |