What is Global Tire Curing Press Machine Market?

The Global Tire Curing Press Machine Market is a crucial segment within the tire manufacturing industry, focusing on the machinery used to cure or vulcanize tires. This process is essential as it transforms the rubber into a more durable and elastic material, making it suitable for use in various vehicles. Tire curing press machines are designed to apply heat and pressure to the tire, ensuring that it achieves the desired shape and properties. The market for these machines is driven by the increasing demand for vehicles worldwide, which in turn boosts the need for tires. Additionally, advancements in technology have led to the development of more efficient and environmentally friendly curing press machines. These machines are integral to the production of high-quality tires, which are essential for vehicle safety and performance. As the automotive industry continues to grow, the demand for tire curing press machines is expected to rise, making this market a vital component of the global manufacturing landscape.

Mechanical Curing Press Machine, Hydraulic Curing Press Machine, Electric Curing Press Machine, Hybrid Curing Press Machine in the Global Tire Curing Press Machine Market:

Mechanical Curing Press Machines are one of the traditional types of machinery used in the tire curing process. These machines rely on mechanical components to apply the necessary pressure and heat to the tire. They are known for their durability and reliability, making them a popular choice in many tire manufacturing facilities. However, they can be less efficient compared to more modern alternatives, as they often require more maintenance and can be less precise in their operations. Despite these drawbacks, mechanical curing press machines remain a staple in the industry due to their cost-effectiveness and proven track record. On the other hand, Hydraulic Curing Press Machines utilize hydraulic systems to exert pressure on the tire. These machines offer greater precision and control, allowing for more consistent results. They are also generally quieter and require less maintenance than mechanical machines. The hydraulic systems enable smoother operations and can be adjusted to accommodate different tire sizes and specifications, making them a versatile option for manufacturers. Electric Curing Press Machines represent a more modern approach, using electric motors to drive the curing process. These machines are known for their energy efficiency and reduced environmental impact. They offer precise control over the curing process, which can lead to higher quality tires. Electric machines are also easier to integrate into automated production lines, enhancing overall productivity. However, the initial investment for electric curing press machines can be higher, which may be a consideration for some manufacturers. Lastly, Hybrid Curing Press Machines combine elements of mechanical, hydraulic, and electric systems to offer a balanced approach. These machines aim to leverage the strengths of each type, providing manufacturers with a flexible and efficient solution. Hybrid machines can be tailored to meet specific production needs, offering a customizable option for tire manufacturers. They are designed to optimize energy use and reduce operational costs while maintaining high-quality output. As the tire industry evolves, the demand for advanced curing press machines is likely to grow, with manufacturers seeking solutions that offer both efficiency and sustainability.

All - steel Radial Tires, Semi - steel Radial Tires, Full - fiber Radial Tires in the Global Tire Curing Press Machine Market:

The Global Tire Curing Press Machine Market plays a significant role in the production of various types of radial tires, including all-steel radial tires, semi-steel radial tires, and full-fiber radial tires. All-steel radial tires are known for their durability and strength, making them ideal for heavy-duty vehicles such as trucks and buses. The curing process for these tires requires precise control over temperature and pressure to ensure the steel belts within the tire are properly bonded to the rubber. Tire curing press machines are essential in achieving this level of precision, ensuring that the tires meet the necessary safety and performance standards. Semi-steel radial tires, which combine steel belts with other materials, also benefit from the use of advanced curing press machines. These machines help in maintaining the balance between flexibility and strength, which is crucial for passenger vehicles that require a smooth and comfortable ride. The ability to adjust the curing parameters allows manufacturers to produce tires that offer optimal performance in various driving conditions. Full-fiber radial tires, which use fiber materials instead of steel, require a different approach in the curing process. The use of tire curing press machines ensures that the fibers are evenly distributed and bonded within the tire, providing the necessary strength and durability. These machines allow for precise control over the curing process, which is essential for producing high-quality full-fiber radial tires. As the demand for different types of radial tires continues to grow, the role of tire curing press machines becomes increasingly important. Manufacturers rely on these machines to produce tires that meet the diverse needs of consumers, from heavy-duty applications to everyday passenger vehicles. The ability to customize the curing process for different tire types is a key advantage of modern tire curing press machines, enabling manufacturers to stay competitive in a rapidly evolving market.

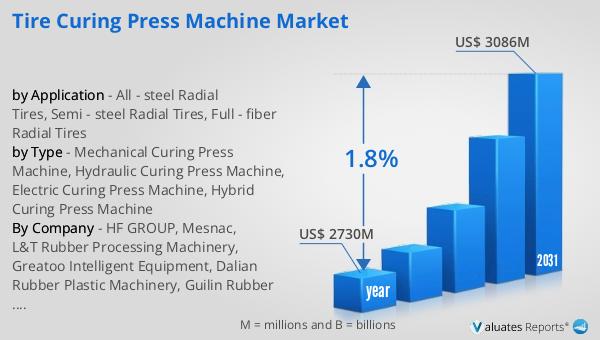

Global Tire Curing Press Machine Market Outlook:

In 2024, the global market for Tire Curing Press Machines was valued at approximately $2.73 billion. By 2031, it is anticipated to expand to a revised size of around $3.086 billion, reflecting a compound annual growth rate (CAGR) of 1.8% over the forecast period. This growth is indicative of the steady demand for tire curing press machines, driven by the continuous expansion of the automotive industry and the increasing need for high-quality tires. From a regional perspective, the Asia-Pacific region stands out as the largest market for tire curing press machines, accounting for more than half of the global market share. This dominance can be attributed to the region's robust automotive manufacturing sector, coupled with the rising demand for vehicles in countries such as China and India. The Asia-Pacific region's significant market share underscores the importance of tire curing press machines in supporting the region's automotive industry. As the market continues to evolve, manufacturers are likely to focus on developing more efficient and sustainable tire curing press machines to meet the growing demands of the industry. The steady growth of the global tire curing press machine market highlights the critical role these machines play in the production of high-quality tires, essential for vehicle safety and performance.

| Report Metric | Details |

| Report Name | Tire Curing Press Machine Market |

| Accounted market size in year | US$ 2730 million |

| Forecasted market size in 2031 | US$ 3086 million |

| CAGR | 1.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HF GROUP, Mesnac, L&T Rubber Processing Machinery, Greatoo Intelligent Equipment, Dalian Rubber Plastic Machinery, Guilin Rubber Machinery, Uzer Makina, McNeil & NRM, Cima Impianti, Mitsubishi Heavy Industries, ARP Technology, Shaoxing Jingcheng Rubber&Plastic Machinery, SIMPAC Industrial Machinery, Hebert, AMCL Machinery, Macrodyne Technologies, Himile, Rongsheng Machinery, Yiyang Rubber&Plastics Machinery, Weiling Rubber & Plastics Machinery, DoubleStar Group, Alwin Machinery, Fujian Sanming Shuanglun Chemical Industry Machinery, Desiree Industrial, Zhejiang Rongsheng Machinery, Qingdao Delphy Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |