What is Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market?

The Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market is a dynamic and evolving sector within the chemical industry. SMA copolymers are versatile materials known for their unique properties, which include excellent heat resistance, transparency, and compatibility with various other polymers. These characteristics make them highly sought after in numerous applications across different industries. The market for SMA copolymers is driven by the increasing demand for high-performance materials that can meet the rigorous requirements of modern manufacturing processes. As industries continue to innovate and develop new products, the need for materials that offer both functionality and durability becomes more pronounced. The global market for SMA copolymers is characterized by a diverse range of applications, from automotive and electronics to packaging and healthcare. This diversity is a testament to the adaptability of SMA copolymers and their ability to meet the specific needs of various industries. As the market continues to grow, manufacturers are investing in research and development to enhance the properties of SMA copolymers and expand their applications. This ongoing innovation is expected to drive the market forward, offering new opportunities for growth and development in the coming years.

in the Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market:

In the Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market, various types of SMA copolymers are utilized by customers based on their specific needs and applications. One of the primary types is the random copolymer, which is widely used due to its excellent transparency and compatibility with other polymers. This type of SMA copolymer is often employed in the production of transparent films and coatings, where clarity and aesthetic appeal are crucial. Another type is the alternating copolymer, which is known for its superior heat resistance and mechanical strength. This makes it ideal for applications in the automotive and electronics industries, where materials are required to withstand high temperatures and mechanical stress. Additionally, SMA copolymers can be modified to enhance specific properties, such as impact resistance or flexibility, making them suitable for a broader range of applications. For instance, in the packaging industry, SMA copolymers are used to create flexible and durable packaging materials that can protect products during transportation and storage. In the healthcare sector, SMA copolymers are utilized in the production of medical devices and equipment, where their biocompatibility and stability are essential. The versatility of SMA copolymers is further demonstrated by their use in the construction industry, where they are employed as additives in paints and coatings to improve adhesion and durability. As the demand for high-performance materials continues to grow, the range of SMA copolymer types available in the market is expected to expand, offering customers more options to meet their specific needs. Manufacturers are continually exploring new formulations and processing techniques to enhance the properties of SMA copolymers and develop new applications. This ongoing innovation is crucial for maintaining the competitiveness of the SMA copolymer market and meeting the evolving demands of customers across different industries. The ability to tailor SMA copolymers to specific applications is a key factor driving their adoption in various sectors, as it allows manufacturers to create customized solutions that meet the unique requirements of their customers. As a result, the Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market is poised for continued growth and development, driven by the increasing demand for versatile and high-performance materials.

in the Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market:

The applications of Global Styrene Maleic Anhydride (SMA) Copolymers are diverse and span across multiple industries, reflecting the material's versatility and adaptability. In the automotive industry, SMA copolymers are used in the production of interior and exterior components, where their heat resistance and mechanical strength are highly valued. These properties ensure that the components can withstand the harsh conditions of automotive environments, such as high temperatures and mechanical stress. Additionally, SMA copolymers are used in the production of adhesives and sealants, which are essential for ensuring the structural integrity and performance of vehicles. In the electronics industry, SMA copolymers are employed in the manufacturing of electronic components and devices, where their excellent electrical insulation properties are crucial. These materials help protect sensitive electronic components from damage and ensure their reliable performance. The packaging industry also benefits from the unique properties of SMA copolymers, as they are used to create flexible and durable packaging materials that can protect products during transportation and storage. In the healthcare sector, SMA copolymers are utilized in the production of medical devices and equipment, where their biocompatibility and stability are essential. These materials are used in applications such as drug delivery systems, where they help ensure the safe and effective delivery of medications to patients. The construction industry also makes use of SMA copolymers, particularly in the production of paints and coatings. These materials are used as additives to improve the adhesion and durability of coatings, ensuring that they can withstand the harsh conditions of construction environments. The versatility of SMA copolymers is further demonstrated by their use in the production of consumer goods, where they are used to create products that are both functional and aesthetically pleasing. As the demand for high-performance materials continues to grow, the range of applications for SMA copolymers is expected to expand, offering new opportunities for growth and development in the market. Manufacturers are continually exploring new applications and processing techniques to enhance the properties of SMA copolymers and meet the evolving demands of customers across different industries. This ongoing innovation is crucial for maintaining the competitiveness of the SMA copolymer market and ensuring its continued growth and development.

Global Styrene Maleic Anhydride (SMA) Copolymer Sales Market Outlook:

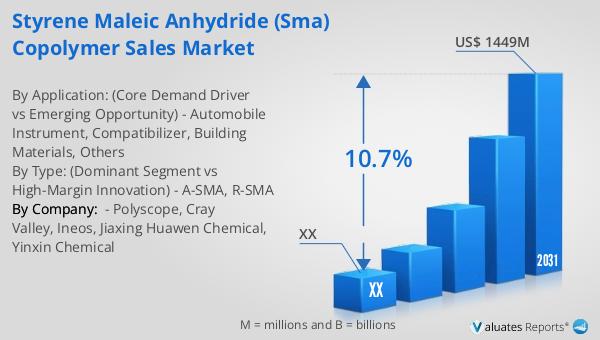

The global market for Styrene Maleic Anhydride (SMA) Copolymers is poised for significant growth in the coming years. In 2024, the market size was valued at approximately $718 million, and it is projected to reach an adjusted size of $1,449 million by 2031, reflecting a compound annual growth rate (CAGR) of 10.7% during the forecast period from 2025 to 2031. This impressive growth is indicative of the increasing demand for SMA copolymers across various industries, driven by their unique properties and versatility. The market is dominated by the top three manufacturers, who collectively hold a substantial share of about 90%. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and differentiation for manufacturers looking to capture market share. In terms of product segments, RSMA (Random Styrene Maleic Anhydride) is the largest, accounting for over 85% of the market share. This dominance is due to the widespread use of RSMA in applications that require excellent transparency and compatibility with other polymers. As the market continues to evolve, manufacturers are expected to focus on expanding their product offerings and enhancing the properties of SMA copolymers to meet the diverse needs of customers across different industries. This ongoing innovation is crucial for maintaining the competitiveness of the SMA copolymer market and ensuring its continued growth and development.

| Report Metric | Details |

| Report Name | Styrene Maleic Anhydride (SMA) Copolymer Sales Market |

| Forecasted market size in 2031 | US$ 1449 million |

| CAGR | 10.7% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Polyscope, Cray Valley, Ineos, Jiaxing Huawen Chemical, Yinxin Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |