What is Global Laser Lift-Off (LLO) Machines Market?

The Global Laser Lift-Off (LLO) Machines Market is a specialized segment within the broader laser technology industry, focusing on machines that utilize laser technology to separate thin films from substrates. These machines are pivotal in industries where precision and efficiency are paramount, such as electronics and display manufacturing. The LLO process involves using a laser to lift off a thin film from a substrate without damaging either component, which is crucial in the production of delicate electronic components. This market is driven by the increasing demand for advanced electronic devices, which require precise and efficient manufacturing processes. As technology continues to evolve, the need for high-quality, reliable LLO machines is expected to grow, making this market an essential part of the global manufacturing landscape. The market is characterized by a few key players who dominate the industry, providing cutting-edge technology and innovative solutions to meet the growing demands of various sectors. The continuous advancements in laser technology and the increasing application of LLO machines in new areas are likely to further propel the growth of this market in the coming years.

Excimer Lasers Lift-Off (LLO) Machines, DPSS Lasers Lift-Off (LLO) Machines in the Global Laser Lift-Off (LLO) Machines Market:

Excimer Lasers Lift-Off (LLO) Machines and DPSS (Diode-Pumped Solid-State) Lasers Lift-Off (LLO) Machines are two prominent types of laser lift-off technologies used in the Global Laser Lift-Off (LLO) Machines Market. Excimer lasers are gas lasers that emit ultraviolet light and are known for their precision and ability to produce high-quality results. They are particularly effective in applications requiring fine detail and minimal thermal damage, making them ideal for industries like electronics and display manufacturing. The excimer laser's ability to deliver short, intense pulses of ultraviolet light allows it to lift off thin films with high precision, which is crucial in the production of OLED displays and other delicate electronic components. On the other hand, DPSS lasers are solid-state lasers that use a diode laser to pump a solid gain medium. They are known for their efficiency, stability, and ability to produce high-power laser beams. DPSS lasers are versatile and can be used in a variety of applications, including materials processing, medical procedures, and scientific research. In the context of LLO machines, DPSS lasers offer a reliable and efficient solution for lifting off thin films from substrates, providing manufacturers with the flexibility and precision needed to produce high-quality electronic components. Both excimer and DPSS lasers have their unique advantages and are chosen based on the specific requirements of the application. The choice between excimer and DPSS lasers often depends on factors such as the type of material being processed, the desired precision, and the specific application requirements. As the demand for advanced electronic devices continues to grow, the need for efficient and precise LLO machines is expected to increase, driving further innovation and development in both excimer and DPSS laser technologies. The Global Laser Lift-Off (LLO) Machines Market is poised for growth as manufacturers seek to improve the efficiency and quality of their production processes, and both excimer and DPSS lasers will play a crucial role in meeting these demands.

OLED, Others in the Global Laser Lift-Off (LLO) Machines Market:

The usage of Global Laser Lift-Off (LLO) Machines Market in areas such as OLED and others is significant due to the precision and efficiency these machines offer. In the OLED (Organic Light Emitting Diodes) industry, LLO machines are essential for the production of high-quality displays. OLED technology is known for its superior display quality, offering vibrant colors, deep blacks, and energy efficiency. The production of OLED displays requires the precise removal of thin films from substrates, a process that is efficiently handled by LLO machines. The ability of LLO machines to lift off thin films without damaging the substrate is crucial in maintaining the integrity and performance of OLED displays. This precision ensures that the displays are free from defects, providing consumers with high-quality visual experiences. Beyond OLED, LLO machines are also used in other industries where thin film removal is necessary. This includes the semiconductor industry, where LLO machines are used in the production of microchips and other electronic components. The ability to precisely remove thin films without damaging the underlying substrate is crucial in the semiconductor industry, where even the smallest defect can lead to significant performance issues. Additionally, LLO machines are used in the production of flexible electronics, which are becoming increasingly popular due to their versatility and potential applications in various fields. The precision and efficiency of LLO machines make them ideal for the production of flexible electronic components, ensuring that they meet the high standards required for commercial use. As technology continues to advance, the applications of LLO machines are expected to expand, further driving the growth of the Global Laser Lift-Off (LLO) Machines Market. The versatility and precision of LLO machines make them an invaluable tool in the production of advanced electronic devices, and their importance is only expected to grow as the demand for high-quality, reliable electronic components increases.

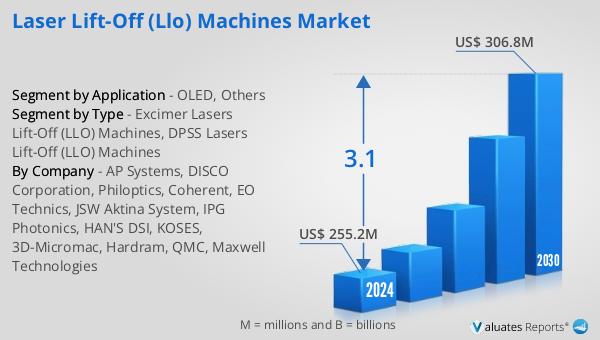

Global Laser Lift-Off (LLO) Machines Market Outlook:

The global market for Laser Lift-Off (LLO) Machines was valued at $262 million in 2024 and is anticipated to grow to $324 million by 2031, with a compound annual growth rate (CAGR) of 3.1% during the forecast period. The market is dominated by the top five manufacturers, namely AP Systems, DISCO Corporation, Philoptics, Coherent, and EO Technics, which together hold over 70% of the market share. AP Systems leads the pack with a market share exceeding 45%. China emerges as the most significant consumer market for LLO machines, accounting for more than 55% of the global consumption. In terms of types, excimer lasers LLO machines dominate with a market share of over 75%. When it comes to applications, OLED technology is the primary driver, representing more than 80% of the market. This data highlights the concentrated nature of the market, with a few key players and regions driving the majority of demand and production. The dominance of excimer lasers and the significant role of OLED applications underscore the importance of precision and quality in the LLO machines market. As the market continues to evolve, these factors are likely to remain central to its growth and development.

| Report Metric | Details |

| Report Name | Laser Lift-Off (LLO) Machines Market |

| Accounted market size in year | US$ 262 million |

| Forecasted market size in 2031 | US$ 324 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AP Systems, DISCO Corporation, Philoptics, Coherent, EO Technics, JSW Aktina System, IPG Photonics, HAN'S DSI, KOSES, 3D-Micromac, Hardram, QMC, Maxwell Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |