What is Global Pharmaceutical Filtration Centrifuges Market?

The Global Pharmaceutical Filtration Centrifuges Market is a specialized segment within the broader pharmaceutical industry, focusing on the equipment used for separating solids from liquids in pharmaceutical production processes. Filtration centrifuges are essential in ensuring the purity and quality of pharmaceutical products by efficiently removing impurities and unwanted particles. These centrifuges operate by spinning at high speeds, which forces the solid particles to separate from the liquid due to centrifugal force. The market for these centrifuges is driven by the increasing demand for high-quality pharmaceuticals, advancements in technology, and stringent regulatory requirements for drug manufacturing. As the pharmaceutical industry continues to grow, particularly with the rise of biologics and complex drug formulations, the need for advanced filtration solutions becomes even more critical. This market encompasses various types of centrifuges, each designed to meet specific filtration needs, ensuring that pharmaceutical companies can produce safe and effective medications. The global reach of this market highlights its importance, as pharmaceutical companies worldwide rely on these centrifuges to maintain the integrity and efficacy of their products.

Horizontal Peeler Centrifuges, Top Discharge Centrifuges, Vertical Peeler Centrifuges, Inverting Filter Centrifuges in the Global Pharmaceutical Filtration Centrifuges Market:

Horizontal Peeler Centrifuges, Top Discharge Centrifuges, Vertical Peeler Centrifuges, and Inverting Filter Centrifuges are all integral components of the Global Pharmaceutical Filtration Centrifuges Market, each offering unique advantages for specific applications. Horizontal Peeler Centrifuges are widely used due to their efficiency in handling large volumes of material. They operate by spinning the material horizontally, allowing for continuous processing and easy discharge of the solid cake. This type of centrifuge is particularly beneficial in processes where high throughput and minimal downtime are crucial. Top Discharge Centrifuges, on the other hand, are designed for batch processing and are ideal for applications requiring gentle handling of delicate products. The solids are discharged from the top, which minimizes product damage and ensures high purity levels. Vertical Peeler Centrifuges are similar to their horizontal counterparts but are oriented vertically. This design allows for a smaller footprint, making them suitable for facilities with limited space. They are known for their versatility and can handle a wide range of materials, from fine chemicals to pharmaceuticals. Inverting Filter Centrifuges offer a unique advantage with their ability to invert the filter cloth, allowing for easy and complete discharge of the solid cake. This feature reduces the risk of contamination and ensures consistent product quality. These centrifuges are particularly useful in applications where product purity is paramount. Each type of centrifuge plays a vital role in the pharmaceutical filtration process, providing solutions that cater to the diverse needs of the industry. As the demand for high-quality pharmaceuticals continues to rise, the importance of these centrifuges in ensuring product integrity and efficiency cannot be overstated.

Pharmaceutical Industry, Chemical Industry, Food Industry, Others in the Global Pharmaceutical Filtration Centrifuges Market:

The Global Pharmaceutical Filtration Centrifuges Market finds its application across various industries, including the pharmaceutical, chemical, and food industries, as well as other sectors. In the pharmaceutical industry, these centrifuges are indispensable for the production of high-purity drugs. They ensure that active pharmaceutical ingredients (APIs) are free from impurities, which is crucial for the safety and efficacy of medications. The ability to handle complex formulations and biologics makes these centrifuges a vital component in modern drug manufacturing. In the chemical industry, filtration centrifuges are used to separate solids from liquids in the production of fine chemicals and intermediates. The precision and efficiency of these centrifuges make them ideal for processes that require high levels of purity and consistency. The food industry also benefits from the use of filtration centrifuges, particularly in the production of food additives, flavors, and other ingredients. These centrifuges help ensure that food products meet stringent quality standards and are free from contaminants. Beyond these industries, filtration centrifuges are used in various other sectors, including environmental and wastewater treatment, where they play a crucial role in separating solids from liquids to ensure clean and safe water. The versatility and efficiency of these centrifuges make them an essential tool in any industry where the separation of solids and liquids is required. As industries continue to evolve and demand higher quality standards, the role of filtration centrifuges in ensuring product integrity and safety becomes increasingly important.

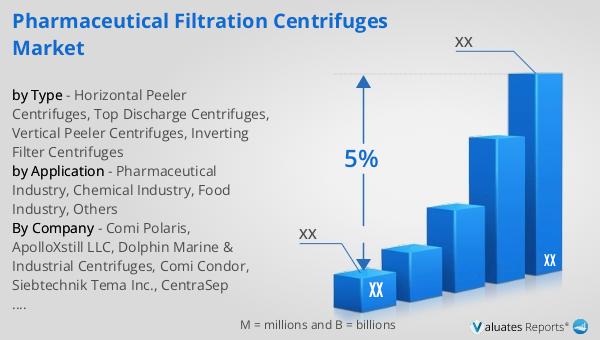

Global Pharmaceutical Filtration Centrifuges Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory underscores the expanding demand for pharmaceutical products worldwide, driven by factors such as an aging population, increased prevalence of chronic diseases, and advancements in drug development. In comparison, the chemical drug market has shown a steady increase, growing from 1,005 billion USD in 2018 to an estimated 1,094 billion USD by 2022. This growth reflects the ongoing demand for chemical-based pharmaceuticals, which continue to play a significant role in the healthcare industry. The expansion of these markets highlights the critical need for advanced filtration solutions, such as those provided by the Global Pharmaceutical Filtration Centrifuges Market, to ensure the production of high-quality and safe pharmaceutical products. As the pharmaceutical and chemical drug markets continue to grow, the importance of efficient and reliable filtration technologies becomes even more pronounced, supporting the industry's efforts to meet the increasing global demand for effective medications.

| Report Metric | Details |

| Report Name | Pharmaceutical Filtration Centrifuges Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Comi Polaris, ApolloXstill LLC, Dolphin Marine & Industrial Centrifuges, Comi Condor, Siebtechnik Tema Inc., CentraSep Centrifuges, Separators, Inc., Ferrum Inc., Bhs-Filtration, Inc., Hoffmann Filter, Scilogex, LLC, B&P Littleford, Heinkel Drying and Separation Group, Flottweg Separation Technology, Inc., CenTex Centrifuge, LLC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |