What is Global Medical Grade Pad Printing Ink Market?

The Global Medical Grade Pad Printing Ink Market is a specialized segment within the broader printing ink industry, focusing on inks used for printing on medical devices and equipment. These inks are formulated to meet stringent safety and quality standards, ensuring they are non-toxic and biocompatible, which is crucial for applications in the healthcare sector. The market is driven by the increasing demand for medical devices, which require precise and durable markings for identification, branding, and regulatory compliance. Medical grade pad printing inks are used to print on a variety of substrates, including plastics, metals, and glass, which are commonly used in medical devices. The inks must adhere well to these surfaces and withstand sterilization processes without degrading. As the healthcare industry continues to grow, particularly with advancements in medical technology and an aging global population, the demand for high-quality medical grade pad printing inks is expected to rise. This market is characterized by continuous innovation, with manufacturers developing new formulations to improve performance and meet evolving regulatory requirements. The global reach of this market is expanding, with significant growth opportunities in emerging economies where healthcare infrastructure is developing rapidly.

Solvent-based, UV Curing in the Global Medical Grade Pad Printing Ink Market:

Solvent-based and UV curing inks are two primary types of inks used in the Global Medical Grade Pad Printing Ink Market, each with distinct characteristics and applications. Solvent-based inks are traditional inks that use organic solvents as a carrier for the pigments. These inks are known for their excellent adhesion properties, making them suitable for printing on a wide range of substrates, including plastics, metals, and glass. The solvents in these inks evaporate quickly, allowing for fast drying times, which is advantageous in high-speed printing operations. However, the use of organic solvents raises environmental and health concerns due to the emission of volatile organic compounds (VOCs). As a result, there is a growing trend towards developing low-VOC or VOC-free solvent-based inks to address these issues. On the other hand, UV curing inks are a more modern alternative that uses ultraviolet light to cure the ink. These inks do not rely on solvents for drying, which eliminates VOC emissions and makes them more environmentally friendly. UV curing inks offer several advantages, including excellent print quality, durability, and resistance to chemicals and abrasion. They are particularly well-suited for applications where high precision and long-lasting prints are required, such as in medical devices. The curing process is almost instantaneous, which can increase production efficiency and reduce turnaround times. However, UV curing inks require specialized equipment, such as UV lamps, which can increase the initial investment cost for printing operations. Despite this, the benefits of UV curing inks, particularly in terms of environmental impact and print quality, are driving their adoption in the medical grade pad printing ink market. Both solvent-based and UV curing inks have their place in the market, with the choice between them depending on specific application requirements, regulatory considerations, and cost factors. As the market evolves, there is a continuous push towards innovation, with manufacturers exploring new formulations and technologies to enhance the performance and sustainability of both types of inks. This includes the development of hybrid inks that combine the benefits of both solvent-based and UV curing technologies, offering improved adhesion, durability, and environmental performance. The ongoing advancements in ink technology are expected to play a crucial role in meeting the growing demand for high-quality, safe, and sustainable printing solutions in the medical sector.

PPE, Medical Device in the Global Medical Grade Pad Printing Ink Market:

The usage of Global Medical Grade Pad Printing Ink Market in areas such as Personal Protective Equipment (PPE) and medical devices is crucial for ensuring safety, compliance, and functionality. In the realm of PPE, medical grade pad printing inks are used to print essential information such as brand logos, size, and usage instructions on items like masks, gloves, and gowns. These inks must adhere well to various materials, including textiles and plastics, and withstand exposure to disinfectants and sterilization processes. The clarity and durability of the prints are vital, as they provide users with critical information that can impact the effectiveness and safety of the PPE. In the medical device sector, pad printing inks are used to mark devices with important details such as serial numbers, measurement indicators, and regulatory compliance symbols. These markings are essential for traceability, quality control, and ensuring that devices meet stringent regulatory standards. The inks used must be biocompatible and resistant to wear and tear, as medical devices often undergo rigorous cleaning and sterilization procedures. The ability to print on complex shapes and surfaces is another advantage of pad printing, making it ideal for medical devices with intricate designs. The demand for medical grade pad printing inks in these areas is driven by the increasing production of PPE and medical devices, particularly in response to global health challenges such as pandemics. As the healthcare industry continues to evolve, the need for high-quality, reliable printing solutions will remain a critical component of ensuring the safety and effectiveness of medical products. Manufacturers are continually innovating to develop inks that meet the highest standards of performance and safety, addressing the unique challenges of printing on medical products. This includes the development of inks that can withstand harsh sterilization processes, adhere to a wide range of substrates, and provide clear, durable prints that meet regulatory requirements. The role of medical grade pad printing inks in the healthcare sector is indispensable, contributing to the overall quality and safety of medical products and equipment.

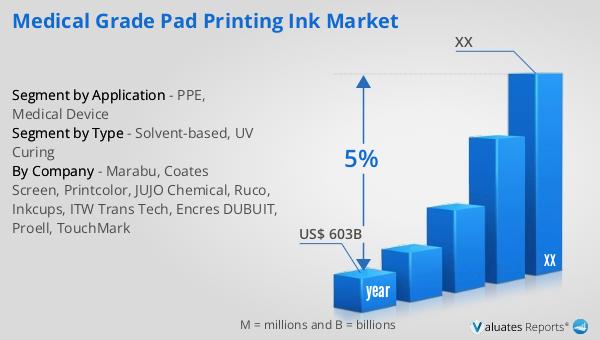

Global Medical Grade Pad Printing Ink Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years.

| Report Metric | Details |

| Report Name | Medical Grade Pad Printing Ink Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Marabu, Coates Screen, Printcolor, JUJO Chemical, Ruco, Inkcups, ITW Trans Tech, Encres DUBUIT, Proell, TouchMark |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |