What is Global Pharmaceutical Grade Cation Exchange Resins Market?

The Global Pharmaceutical Grade Cation Exchange Resins Market is a specialized segment within the broader pharmaceutical industry, focusing on the production and application of cation exchange resins that meet stringent pharmaceutical standards. These resins are used primarily for their ability to exchange cations in a solution, which is a critical function in various pharmaceutical processes. They are essential in the purification and separation processes, ensuring that pharmaceutical products meet the required purity levels. The market for these resins is driven by the increasing demand for high-quality pharmaceutical products, as well as the growing complexity of drug formulations that require advanced purification techniques. As pharmaceutical companies strive to meet regulatory standards and improve the efficacy and safety of their products, the demand for pharmaceutical-grade cation exchange resins continues to rise. This market is characterized by continuous innovation and development, as manufacturers seek to enhance the performance and efficiency of their resins to meet the evolving needs of the pharmaceutical industry. The global reach of this market is significant, with major players operating in various regions to cater to the diverse needs of pharmaceutical manufacturers worldwide.

Strong Acidc, Weakly Acidic in the Global Pharmaceutical Grade Cation Exchange Resins Market:

In the Global Pharmaceutical Grade Cation Exchange Resins Market, two primary types of resins are utilized: strong acidic and weakly acidic resins. Strong acidic cation exchange resins are characterized by their ability to exchange cations across a wide pH range, making them highly versatile and effective in various pharmaceutical applications. These resins typically contain sulfonic acid groups, which provide them with a high exchange capacity and stability under different conditions. They are particularly useful in processes that require the removal of cations from solutions, such as water softening and demineralization. In the pharmaceutical industry, strong acidic resins are often employed in the purification of active pharmaceutical ingredients (APIs) and the removal of impurities that could affect the quality and efficacy of the final product. Their robust nature allows them to withstand harsh conditions, making them suitable for use in high-temperature and high-pressure environments. On the other hand, weakly acidic cation exchange resins contain carboxylic acid groups, which give them a different set of properties compared to their strong acidic counterparts. These resins are more sensitive to pH changes and are typically used in applications where a more selective ion exchange process is required. Weakly acidic resins are particularly effective in the separation and purification of specific ions, making them ideal for use in processes that require a high degree of precision and control. In the pharmaceutical industry, they are often used in the purification of complex drug formulations, where the selective removal of certain ions is crucial to achieving the desired product quality. The ability of weakly acidic resins to operate effectively at lower pH levels also makes them suitable for use in processes that involve the treatment of acidic solutions. Both strong acidic and weakly acidic cation exchange resins play a vital role in the pharmaceutical industry, providing essential functions that contribute to the production of high-quality pharmaceutical products. The choice between these two types of resins depends on the specific requirements of the application, including the desired level of ion exchange, the nature of the solution being treated, and the operating conditions of the process. As the pharmaceutical industry continues to evolve, the demand for advanced cation exchange resins that offer enhanced performance and efficiency is expected to grow. Manufacturers are continually investing in research and development to improve the properties of these resins, ensuring that they meet the increasingly stringent standards of the pharmaceutical industry. The ongoing innovation in this field is likely to lead to the development of new resin technologies that offer even greater capabilities, further expanding the potential applications of cation exchange resins in the pharmaceutical sector.

Controlled Drug Release, Odor Masking, Others in the Global Pharmaceutical Grade Cation Exchange Resins Market:

The Global Pharmaceutical Grade Cation Exchange Resins Market finds its applications in several critical areas, including controlled drug release, odor masking, and other specialized uses. In controlled drug release, cation exchange resins play a pivotal role by modulating the release rate of active pharmaceutical ingredients (APIs) in the body. This is achieved by incorporating the APIs into the resin matrix, which then releases the drug at a controlled rate as it exchanges ions with the surrounding biological fluids. This controlled release mechanism is crucial for maintaining therapeutic drug levels in the bloodstream over an extended period, enhancing the efficacy and safety of the medication. It is particularly beneficial for drugs that require precise dosing schedules or have a narrow therapeutic index, as it helps to minimize side effects and improve patient compliance. In the realm of odor masking, cation exchange resins are employed to neutralize or reduce unpleasant odors associated with certain pharmaceutical formulations. This is particularly important for oral medications, where the taste and smell of the drug can significantly impact patient acceptance and adherence to the treatment regimen. By incorporating cation exchange resins into the formulation, manufacturers can effectively mask undesirable odors, improving the overall sensory experience for the patient. This application is especially relevant for pediatric and geriatric populations, who may be more sensitive to the taste and smell of medications. Beyond controlled drug release and odor masking, cation exchange resins are also used in a variety of other pharmaceutical applications. These include the stabilization of sensitive drug compounds, the enhancement of drug solubility, and the improvement of drug bioavailability. In each of these applications, the unique ion exchange properties of the resins are leveraged to achieve specific formulation goals, ultimately contributing to the development of more effective and patient-friendly pharmaceutical products. The versatility of cation exchange resins makes them an invaluable tool in the pharmaceutical industry, enabling manufacturers to address a wide range of formulation challenges and meet the diverse needs of patients. As the demand for innovative drug delivery systems and patient-centric formulations continues to grow, the role of cation exchange resins in the pharmaceutical industry is expected to expand. Manufacturers are increasingly exploring new ways to harness the potential of these resins, developing novel applications that enhance the performance and appeal of pharmaceutical products. The ongoing advancements in resin technology are likely to lead to the discovery of new uses and benefits, further solidifying the importance of cation exchange resins in the global pharmaceutical market.

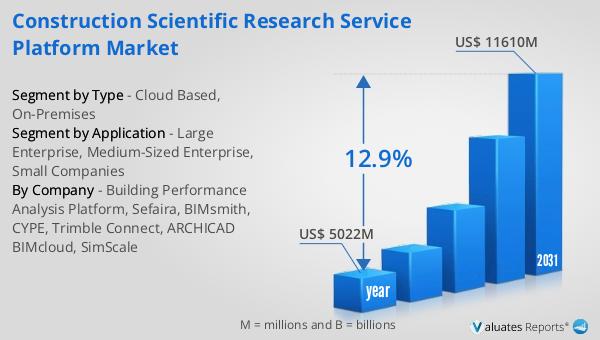

Global Pharmaceutical Grade Cation Exchange Resins Market Outlook:

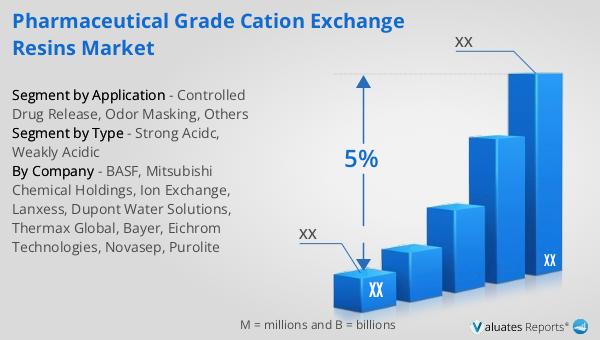

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, demonstrating a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, the rise of chronic diseases, and advancements in drug development technologies. In comparison, the chemical drug market has also shown significant growth, expanding from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This increase reflects the ongoing innovation and development within the chemical drug sector, as manufacturers strive to meet the evolving needs of patients and healthcare providers. The growth of both the global pharmaceutical market and the chemical drug market highlights the dynamic nature of the industry, characterized by continuous advancements in research and development, regulatory changes, and shifting consumer preferences. As pharmaceutical companies seek to capitalize on these trends, the demand for high-quality raw materials and advanced technologies, such as pharmaceutical-grade cation exchange resins, is expected to rise. These resins play a crucial role in ensuring the purity and efficacy of pharmaceutical products, making them an essential component of the drug manufacturing process. The positive outlook for the global pharmaceutical market underscores the importance of innovation and adaptability in the industry. As companies navigate the challenges and opportunities presented by this rapidly evolving landscape, the ability to leverage cutting-edge technologies and materials will be key to maintaining a competitive edge. The continued growth of the market is likely to drive further investment in research and development, leading to the discovery of new treatments and therapies that improve patient outcomes and enhance the quality of life for individuals around the world.

| Report Metric | Details |

| Report Name | Pharmaceutical Grade Cation Exchange Resins Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BASF, Mitsubishi Chemical Holdings, Ion Exchange, Lanxess, Dupont Water Solutions, Thermax Global, Bayer, Eichrom Technologies, Novasep, Purolite |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |