What is Global Pharmaceutical Grade Anion Exchange Resins Market?

The Global Pharmaceutical Grade Anion Exchange Resins Market is a specialized segment within the broader chemical industry, focusing on the production and application of anion exchange resins specifically designed for pharmaceutical use. These resins are polymers capable of exchanging particular anions within a solution, making them invaluable in various pharmaceutical processes. They are used to purify and decolorize solutions, remove impurities, and facilitate drug formulation. The demand for pharmaceutical-grade anion exchange resins is driven by the increasing need for high-purity products in the pharmaceutical industry, where even trace impurities can significantly affect drug safety and efficacy. These resins are engineered to meet stringent regulatory standards, ensuring they are safe for use in drug manufacturing. The market is characterized by continuous innovation, with manufacturers developing resins that offer improved performance, greater stability, and enhanced selectivity. As the pharmaceutical industry continues to grow, particularly with the rise of biologics and complex drug formulations, the demand for high-quality anion exchange resins is expected to increase, making this a dynamic and evolving market segment.

Alkaline, Acidic in the Global Pharmaceutical Grade Anion Exchange Resins Market:

In the Global Pharmaceutical Grade Anion Exchange Resins Market, resins are categorized based on their functional groups, primarily into alkaline and acidic types. Alkaline anion exchange resins contain functional groups that are basic in nature, such as quaternary ammonium groups. These resins are particularly effective in capturing and exchanging negatively charged ions, or anions, from solutions. They are widely used in processes where the removal of anions like chloride, sulfate, and nitrate is essential. The alkaline resins are known for their high capacity and efficiency in ion exchange processes, making them suitable for applications requiring stringent purity levels. On the other hand, acidic anion exchange resins possess functional groups that are acidic, such as sulfonic acid groups. These resins are less common in the pharmaceutical industry compared to their alkaline counterparts but are still used in specific applications where the exchange of cations is required. The choice between alkaline and acidic resins depends on the specific requirements of the pharmaceutical process, including the type of ions to be exchanged, the desired purity levels, and the chemical stability needed. Both types of resins play a crucial role in ensuring the quality and safety of pharmaceutical products. The development of these resins involves a deep understanding of polymer chemistry and the specific needs of pharmaceutical applications. Manufacturers invest in research and development to create resins that not only meet regulatory standards but also offer enhanced performance characteristics. This includes improving the resins' resistance to fouling, increasing their mechanical strength, and optimizing their ion exchange capacity. The market for these resins is highly competitive, with numerous players striving to offer products that provide the best balance of performance, cost, and compliance with regulatory requirements. As the pharmaceutical industry continues to evolve, the demand for specialized anion exchange resins is expected to grow, driven by the need for more efficient and effective drug manufacturing processes. The use of these resins in pharmaceutical applications is not limited to ion exchange processes alone. They are also employed in drug delivery systems, where they can help control the release of active pharmaceutical ingredients. This is particularly important in the development of sustained-release formulations, where the resin's ability to bind and release drugs at a controlled rate can significantly enhance therapeutic outcomes. Additionally, anion exchange resins are used in the purification of biologics, where their ability to remove impurities without affecting the biological activity of the product is critical. The versatility of these resins makes them an indispensable tool in the pharmaceutical industry, contributing to the development of safer and more effective medications.

Controlled Drug Release, Odor Masking, Others in the Global Pharmaceutical Grade Anion Exchange Resins Market:

The Global Pharmaceutical Grade Anion Exchange Resins Market finds its applications in several critical areas, including controlled drug release, odor masking, and other specialized uses. In controlled drug release, anion exchange resins are utilized to modulate the release rate of active pharmaceutical ingredients (APIs). By binding the APIs to the resin, the release can be slowed down, allowing for a sustained therapeutic effect over an extended period. This is particularly beneficial in the development of once-daily medications, where maintaining consistent drug levels in the bloodstream is crucial for efficacy and patient compliance. The resins' ability to control drug release is influenced by factors such as the resin's porosity, the strength of the ionic bond between the resin and the drug, and the environmental conditions within the body. In odor masking, anion exchange resins play a vital role in improving the palatability of oral medications. Many drugs have an unpleasant taste or odor, which can be a significant barrier to patient adherence, especially in pediatric and geriatric populations. By adsorbing the odor-causing compounds onto the resin, the overall sensory experience of the medication can be improved, making it more acceptable to patients. This application requires resins with high adsorption capacity and selectivity to ensure that the active ingredients are not adversely affected. Beyond these applications, anion exchange resins are also used in various other pharmaceutical processes. They are employed in the purification of APIs, where their ability to remove impurities and contaminants is critical for ensuring product safety and efficacy. In the production of biologics, anion exchange resins are used to purify proteins and other macromolecules, where their selectivity and capacity are essential for maintaining the biological activity of the product. Additionally, these resins are used in the stabilization of sensitive compounds, where their ability to bind and protect the active ingredients from degradation can significantly extend the shelf life of the product. The versatility of anion exchange resins makes them an invaluable tool in the pharmaceutical industry, contributing to the development of safer, more effective, and more patient-friendly medications. As the industry continues to innovate and evolve, the demand for high-quality anion exchange resins is expected to grow, driven by the need for more efficient and effective drug manufacturing processes.

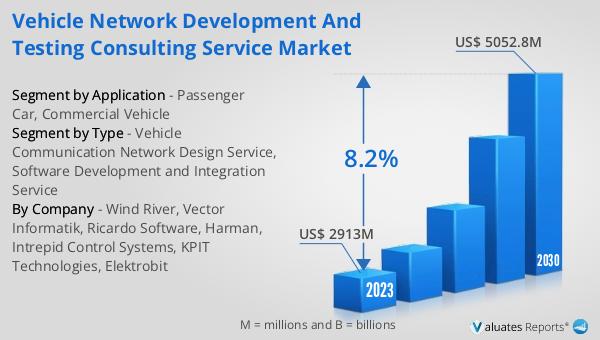

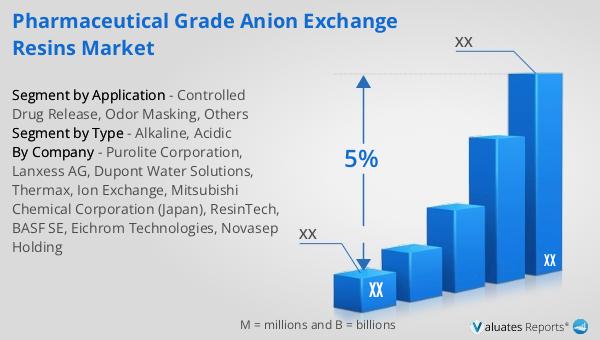

Global Pharmaceutical Grade Anion Exchange Resins Market Outlook:

The outlook for the Global Pharmaceutical Grade Anion Exchange Resins Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with a projected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development technologies. In comparison, the chemical drug market, which forms a significant part of the pharmaceutical industry, was estimated to grow from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth reflects the ongoing demand for chemical-based medications, which continue to play a crucial role in healthcare despite the rise of biologics and other advanced therapies. The increasing complexity of drug formulations and the need for high-purity products are expected to drive the demand for pharmaceutical-grade anion exchange resins, as they are essential for ensuring the quality and safety of pharmaceutical products. As the pharmaceutical industry continues to expand, the market for these specialized resins is likely to grow, driven by the need for more efficient and effective drug manufacturing processes.

| Report Metric | Details |

| Report Name | Pharmaceutical Grade Anion Exchange Resins Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Purolite Corporation, Lanxess AG, Dupont Water Solutions, Thermax, Ion Exchange, Mitsubishi Chemical Corporation (Japan), ResinTech, BASF SE, Eichrom Technologies, Novasep Holding |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |