What is Global Alloy Plating Chemicals Market?

The Global Alloy Plating Chemicals Market is a dynamic and essential segment of the chemical industry, playing a crucial role in various industrial applications. Alloy plating involves the deposition of a metal alloy onto a substrate to enhance its properties, such as corrosion resistance, hardness, and aesthetic appeal. The chemicals used in this process are specifically formulated to ensure the efficient and effective deposition of the alloy onto the desired surface. These chemicals are vital in industries where durability and performance are paramount, such as automotive, electronics, and aerospace. The market for alloy plating chemicals is driven by the increasing demand for high-performance materials that can withstand harsh environments and extend the lifespan of products. As industries continue to innovate and develop new technologies, the need for advanced plating solutions grows, making the Global Alloy Plating Chemicals Market a critical component of modern manufacturing processes. The market is characterized by continuous research and development efforts aimed at improving the efficiency and environmental sustainability of plating processes, ensuring that it remains a vital part of the global industrial landscape.

Pretreatment Agent, Electroplating Additive, Post-Treatment Agent in the Global Alloy Plating Chemicals Market:

In the Global Alloy Plating Chemicals Market, several key components play a pivotal role in the plating process, including Pretreatment Agents, Electroplating Additives, and Post-Treatment Agents. Pretreatment Agents are crucial as they prepare the surface of the substrate for plating. This involves cleaning and conditioning the surface to ensure optimal adhesion of the plating material. These agents remove impurities, oxides, and other contaminants that could hinder the plating process. By creating a clean and receptive surface, pretreatment agents enhance the quality and durability of the final plated product. Electroplating Additives are specialized chemicals added to the plating bath to improve the deposition process. They help control the plating rate, enhance the uniformity of the coating, and improve the physical properties of the plated layer. These additives can include brighteners, levelers, and wetting agents, each serving a specific function to achieve the desired plating characteristics. Brighteners, for example, enhance the luster and smoothness of the plated surface, while levelers ensure an even distribution of the plating material. Wetting agents reduce surface tension, allowing the plating solution to spread evenly over the substrate. Post-Treatment Agents are used after the plating process to enhance the properties of the plated layer and ensure its long-term performance. These agents can include passivators, sealants, and anti-tarnish solutions. Passivators form a protective layer on the plated surface, enhancing its corrosion resistance. Sealants provide an additional barrier against environmental factors, while anti-tarnish solutions prevent discoloration and maintain the aesthetic appeal of the plated product. Together, these components form a comprehensive system that ensures the effectiveness and efficiency of the alloy plating process. The continuous development and optimization of these chemicals are essential to meet the evolving demands of various industries, making them a cornerstone of the Global Alloy Plating Chemicals Market.

Automobile, Electrical & Electronics, Home Appliance, Machinery Parts & Components, Others in the Global Alloy Plating Chemicals Market:

The Global Alloy Plating Chemicals Market finds extensive application across various sectors, including the automobile, electrical and electronics, home appliance, machinery parts and components, and other industries. In the automobile industry, alloy plating chemicals are used to enhance the durability and aesthetic appeal of vehicle components. Plated parts are more resistant to corrosion and wear, which is crucial for components exposed to harsh environmental conditions. This not only extends the lifespan of the parts but also improves the overall performance and safety of the vehicle. In the electrical and electronics sector, alloy plating is essential for improving the conductivity and reliability of components. Plated connectors, switches, and circuit boards benefit from enhanced electrical performance and protection against oxidation and corrosion. This ensures the longevity and efficiency of electronic devices, which is critical in a technology-driven world. Home appliances also benefit from alloy plating chemicals, as they enhance the appearance and durability of components such as handles, knobs, and decorative trims. Plated surfaces are easier to clean and maintain, providing a long-lasting and attractive finish that appeals to consumers. In the machinery parts and components industry, alloy plating chemicals are used to improve the wear resistance and lifespan of critical parts. This is particularly important in heavy machinery and equipment that operate under demanding conditions. Plated components can withstand higher levels of stress and friction, reducing the need for frequent replacements and maintenance. Other industries, such as aerospace and medical devices, also rely on alloy plating chemicals to meet stringent performance and safety standards. In aerospace, plated components must withstand extreme temperatures and pressures, while in medical devices, biocompatibility and corrosion resistance are paramount. The versatility and effectiveness of alloy plating chemicals make them indispensable across these diverse applications, driving the growth and innovation within the Global Alloy Plating Chemicals Market.

Global Alloy Plating Chemicals Market Outlook:

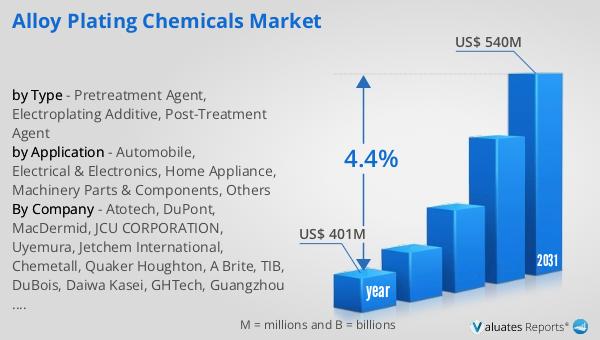

The global market for Alloy Plating Chemicals was valued at approximately $401 million in 2024, with projections indicating a growth trajectory that will see it reach around $540 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.4% over the forecast period. This upward trend reflects the increasing demand for high-performance materials across various industries, driven by the need for enhanced durability, corrosion resistance, and aesthetic appeal. As industries continue to evolve and innovate, the demand for advanced plating solutions is expected to rise, contributing to the market's expansion. The projected growth also underscores the importance of continuous research and development efforts aimed at improving the efficiency and environmental sustainability of plating processes. By investing in innovative solutions and technologies, the Global Alloy Plating Chemicals Market is poised to meet the evolving needs of industries worldwide, ensuring its relevance and importance in the global industrial landscape. This growth trajectory highlights the critical role that alloy plating chemicals play in modern manufacturing processes, making them an essential component of the global economy.

| Report Metric | Details |

| Report Name | Alloy Plating Chemicals Market |

| Accounted market size in year | US$ 401 million |

| Forecasted market size in 2031 | US$ 540 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atotech, DuPont, MacDermid, JCU CORPORATION, Uyemura, Jetchem International, Chemetall, Quaker Houghton, A Brite, TIB, DuBois, Daiwa Kasei, GHTech, Guangzhou Sanfu, Guangdong Dazhi Chem, Wuhan Fengfan Electrochemical Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |