What is Global Single Effect Concentrating Evaporator Market?

The Global Single Effect Concentrating Evaporator Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to concentrate solutions by evaporating the solvent, typically water, from a solution. These evaporators are widely used in industries where the concentration of liquids is necessary, such as in the production of chemicals, pharmaceuticals, and food products. The single effect concentrating evaporator operates by heating the solution to its boiling point, causing the solvent to evaporate and leaving behind a more concentrated solution. This process is crucial for industries that require precise concentration levels for their products. The market for these evaporators is driven by the increasing demand for efficient and cost-effective concentration solutions, as well as the need for energy-efficient equipment that can reduce operational costs. Additionally, advancements in technology have led to the development of more efficient and environmentally friendly evaporators, further boosting market growth. The market is characterized by a diverse range of products, catering to various industrial needs, and is expected to continue growing as industries seek to optimize their production processes.

Batch Type, Continuous Type in the Global Single Effect Concentrating Evaporator Market:

The Global Single Effect Concentrating Evaporator Market can be categorized into two main types: Batch Type and Continuous Type evaporators. Batch Type evaporators are designed to process a fixed amount of solution in each cycle. They are typically used in applications where the production volume is relatively low or where the process requires frequent changes in the type of solution being concentrated. These evaporators are known for their simplicity and ease of operation, making them ideal for small-scale operations or research and development purposes. The batch process involves loading the solution into the evaporator, heating it to the desired temperature, and then allowing the solvent to evaporate until the desired concentration is achieved. Once the process is complete, the concentrated solution is removed, and the evaporator is cleaned and prepared for the next batch. This type of evaporator is particularly useful in industries where flexibility and adaptability are important, as it allows for easy adjustments to the process parameters. On the other hand, Continuous Type evaporators are designed for large-scale operations where a constant flow of solution is required. These evaporators are capable of processing large volumes of solution continuously, making them ideal for industries with high production demands. The continuous process involves feeding the solution into the evaporator at a constant rate, where it is heated and concentrated as it flows through the system. The concentrated solution is then continuously removed from the evaporator, allowing for uninterrupted operation. Continuous Type evaporators are known for their efficiency and ability to handle large volumes of solution, making them a popular choice in industries such as food processing, chemical manufacturing, and pharmaceuticals. They are designed to operate with minimal supervision, reducing labor costs and increasing productivity. Additionally, continuous evaporators are often equipped with advanced control systems that allow for precise monitoring and adjustment of process parameters, ensuring consistent product quality. Both Batch Type and Continuous Type evaporators have their own advantages and are suited to different applications. Batch Type evaporators are ideal for small-scale operations or where flexibility is required, while Continuous Type evaporators are better suited for large-scale operations with high production demands. The choice between the two types depends on factors such as production volume, process requirements, and budget. In recent years, there has been a growing trend towards the use of Continuous Type evaporators, driven by the increasing demand for efficient and cost-effective production solutions. However, Batch Type evaporators continue to play a crucial role in industries where flexibility and adaptability are important. As the Global Single Effect Concentrating Evaporator Market continues to evolve, manufacturers are focusing on developing innovative solutions that combine the advantages of both types, offering greater flexibility and efficiency to meet the diverse needs of their customers.

Chemical Industry, Food, Pharmaceutical, Others in the Global Single Effect Concentrating Evaporator Market:

The Global Single Effect Concentrating Evaporator Market finds extensive usage across various industries, including the Chemical Industry, Food, Pharmaceutical, and others. In the Chemical Industry, these evaporators are essential for processes that require the concentration of chemical solutions. They are used to remove solvents from chemical mixtures, resulting in a more concentrated product. This is particularly important in the production of chemicals such as acids, alkalis, and salts, where precise concentration levels are crucial for product quality and performance. The use of single effect concentrating evaporators in the chemical industry helps to improve process efficiency, reduce energy consumption, and minimize waste, making them an integral part of modern chemical manufacturing processes. In the Food Industry, single effect concentrating evaporators are used to concentrate food products such as fruit juices, dairy products, and sauces. The concentration process helps to enhance the flavor, texture, and shelf life of food products, making them more appealing to consumers. Evaporators are also used to remove excess water from food products, reducing their weight and volume, which can lead to significant cost savings in transportation and storage. The use of single effect concentrating evaporators in the food industry is driven by the increasing demand for high-quality, concentrated food products that meet consumer preferences for taste and convenience. The Pharmaceutical Industry also relies heavily on single effect concentrating evaporators for the production of various pharmaceutical products. These evaporators are used to concentrate active pharmaceutical ingredients (APIs) and other compounds, ensuring that they meet the required potency and purity standards. The concentration process is critical for the production of medications, as it ensures that the final product contains the correct dosage of active ingredients. The use of single effect concentrating evaporators in the pharmaceutical industry helps to improve product quality, reduce production costs, and ensure compliance with regulatory standards. Apart from the Chemical, Food, and Pharmaceutical industries, single effect concentrating evaporators are also used in other sectors such as wastewater treatment, textiles, and paper manufacturing. In wastewater treatment, these evaporators are used to concentrate and remove contaminants from wastewater, reducing the volume of waste that needs to be disposed of and minimizing environmental impact. In the textile industry, evaporators are used to concentrate dyes and other chemicals used in the production of textiles, improving process efficiency and reducing waste. In the paper industry, evaporators are used to concentrate black liquor, a byproduct of the pulping process, which can be used as a fuel source or further processed to extract valuable chemicals. The versatility and efficiency of single effect concentrating evaporators make them an essential tool in a wide range of industrial applications, driving their demand in the global market.

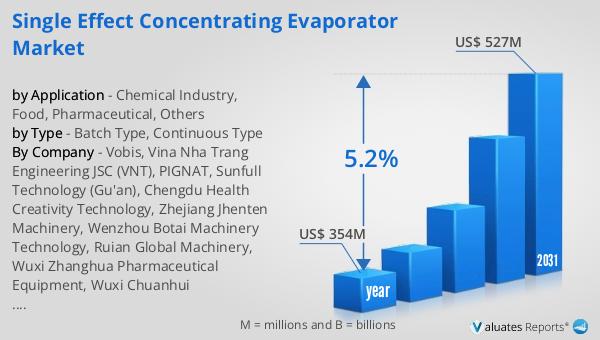

Global Single Effect Concentrating Evaporator Market Outlook:

In 2024, the global market for Single Effect Concentrating Evaporators was valued at approximately $354 million. Looking ahead, this market is anticipated to grow significantly, reaching an estimated size of $527 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. The increasing demand for efficient and cost-effective concentration solutions across various industries is a key driver of this market growth. As industries continue to seek ways to optimize their production processes and reduce operational costs, the demand for advanced evaporators is expected to rise. Additionally, technological advancements in evaporator design and functionality are likely to contribute to market expansion, as they offer improved efficiency and environmental benefits. The market's growth is also supported by the rising need for energy-efficient equipment that can help industries meet their sustainability goals. As a result, the Global Single Effect Concentrating Evaporator Market is poised for steady growth, driven by the increasing adoption of these evaporators in industries such as chemicals, food, pharmaceuticals, and others. This positive market outlook reflects the growing importance of single effect concentrating evaporators in modern industrial processes and their potential to drive efficiency and sustainability in various sectors.

| Report Metric | Details |

| Report Name | Single Effect Concentrating Evaporator Market |

| Accounted market size in year | US$ 354 million |

| Forecasted market size in 2031 | US$ 527 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vobis, Vina Nha Trang Engineering JSC (VNT), PIGNAT, Sunfull Technology (Gu'an), Chengdu Health Creativity Technology, Zhejiang Jhenten Machinery, Wenzhou Botai Machinery Technology, Ruian Global Machinery, Wuxi Zhanghua Pharmaceutical Equipment, Wuxi Chuanhui Thermoelectric Equipment Manufacture, Wenzhou Longqiang Machinery Tech., WTEYA GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |