What is Global Shape Memory Alloys Sales Market?

The Global Shape Memory Alloys Sales Market refers to the worldwide trade and distribution of shape memory alloys (SMAs), which are unique materials known for their ability to return to a pre-defined shape when exposed to certain stimuli, such as temperature changes. These alloys are primarily composed of nickel-titanium, copper-aluminum-nickel, and copper-zinc-aluminum, among others. The market encompasses the production, sales, and application of these materials across various industries, including medical, aerospace, automotive, and consumer electronics. The demand for SMAs is driven by their unique properties, such as superelasticity and high fatigue resistance, which make them suitable for innovative applications. As industries continue to seek advanced materials that offer both functionality and efficiency, the global market for shape memory alloys is expected to grow, with manufacturers focusing on enhancing the performance and cost-effectiveness of these materials to meet diverse industrial needs. The market is characterized by ongoing research and development efforts aimed at discovering new applications and improving the existing capabilities of shape memory alloys.

in the Global Shape Memory Alloys Sales Market:

Shape memory alloys (SMAs) are versatile materials that have found their way into various industries due to their unique properties. The most common type of SMA is the nickel-titanium alloy, often referred to as Nitinol. This alloy is renowned for its excellent shape memory and superelasticity, making it a popular choice in the medical field, particularly for stents and guidewires. Its ability to undergo significant deformation and return to its original shape is invaluable in minimally invasive surgeries. Another type of SMA is the copper-based alloy, which includes copper-aluminum-nickel and copper-zinc-aluminum. These are generally more cost-effective than nickel-titanium alloys and are used in applications where cost is a significant factor. Copper-based SMAs are often utilized in the construction industry for seismic damping devices and in the automotive sector for actuators and sensors. Iron-based SMAs are another category, though less common, they are gaining attention for their potential in large-scale applications due to their lower cost and good mechanical properties. These are being explored for use in civil engineering and infrastructure projects. Each type of SMA offers distinct advantages, and the choice of alloy depends largely on the specific requirements of the application, such as the desired temperature range for activation, the degree of deformation needed, and the cost constraints. The versatility of SMAs allows them to be tailored to meet the needs of various industries, making them a critical component in the development of advanced technologies. As research continues, new types of SMAs are being developed, expanding the possibilities for their use in innovative applications. The global market for shape memory alloys is thus characterized by a diverse range of materials, each with unique properties that cater to the specific demands of different sectors.

in the Global Shape Memory Alloys Sales Market:

Shape memory alloys (SMAs) have a wide range of applications across various industries, thanks to their unique ability to return to a pre-defined shape when exposed to certain stimuli. In the medical field, SMAs are extensively used in the manufacture of stents, guidewires, and orthodontic devices. Their biocompatibility and superelastic properties make them ideal for minimally invasive procedures, allowing for devices that can be inserted in a compact form and then expand to their functional shape within the body. In the aerospace industry, SMAs are used in actuators and adaptive structures, where their ability to change shape in response to temperature changes can be harnessed to improve the performance and efficiency of aircraft components. The automotive industry also benefits from SMAs, particularly in the development of advanced safety systems and fuel-efficient technologies. SMAs are used in actuators for variable geometry turbochargers and in systems designed to improve vehicle aerodynamics. In the consumer electronics sector, SMAs are used in the development of responsive and adaptive devices, such as eyeglass frames that can return to their original shape after being bent. Additionally, SMAs are employed in the construction industry for seismic damping devices, which help to absorb and dissipate energy during earthquakes, thereby enhancing the structural integrity of buildings. The versatility of SMAs allows them to be used in a wide range of applications, each leveraging the unique properties of these materials to achieve improved performance and functionality. As industries continue to seek innovative solutions to complex challenges, the demand for SMAs is expected to grow, driving further research and development in this field.

Global Shape Memory Alloys Sales Market Outlook:

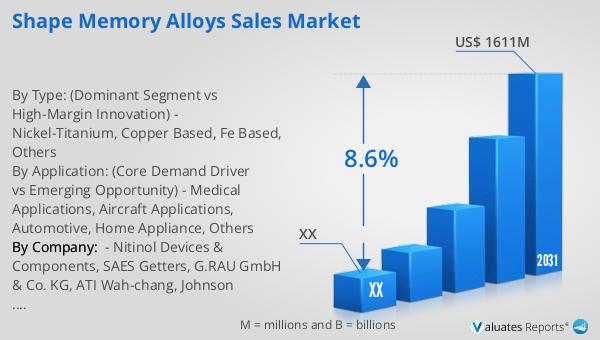

In 2024, the global market for Shape Memory Alloys was valued at approximately $912 million. By 2031, it is projected to reach an adjusted size of around $1,611 million, reflecting a compound annual growth rate (CAGR) of 8.6% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for these unique materials across various industries. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 45%. Among the different types of shape memory alloys, the nickel-titanium segment stands out as the largest, accounting for over 75% of the market share. This dominance is largely due to the superior properties of nickel-titanium alloys, such as their excellent shape memory and superelasticity, which make them highly sought after in the medical and aerospace industries. The market's growth is driven by the continuous advancements in technology and the increasing adoption of SMAs in new applications. As industries strive to enhance efficiency and performance, the demand for advanced materials like shape memory alloys is expected to rise, further fueling the market's expansion. The focus on research and development is crucial in this market, as manufacturers aim to improve the properties of existing alloys and discover new applications to meet the evolving needs of various sectors.

| Report Metric | Details |

| Report Name | Shape Memory Alloys Sales Market |

| Forecasted market size in 2031 | US$ 1611 million |

| CAGR | 8.6% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Nitinol Devices & Components, SAES Getters, G.RAU GmbH & Co. KG, ATI Wah-chang, Johnson Matthey, Fort Wayne Metals, Furukawa Electric, Nippon Steel & Sumitomo Metal, Nippon Seisen, Metalwerks PMD, Ultimate NiTi Technologies, Dynalloy, Grikin, PEIER Tech, Saite Metal, Smart, Baoji Seabird Metal, GEE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |