What is Global Round Granule Granulator Market?

The Global Round Granule Granulator Market is a specialized segment within the broader machinery and equipment industry, focusing on the production and distribution of machines designed to create round granules from various materials. These granulators are essential in numerous industries, including pharmaceuticals, agriculture, and chemicals, where they transform raw materials into uniform, round granules for easier handling, processing, and application. The market is driven by the increasing demand for efficient and consistent granulation processes, which are crucial for product quality and operational efficiency. As industries continue to evolve and seek more sustainable and efficient production methods, the demand for advanced granulation technology is expected to grow. This market encompasses a range of granulators, each designed to meet specific industry needs, from small-scale operations to large industrial applications. The focus on innovation and technological advancement is a key characteristic of this market, as manufacturers strive to develop machines that offer improved performance, energy efficiency, and ease of use. Overall, the Global Round Granule Granulator Market plays a vital role in supporting various industries by providing the tools necessary for effective material processing and product development.

Wet Granulator, Dry Granulator in the Global Round Granule Granulator Market:

In the Global Round Granule Granulator Market, two primary types of granulators are widely used: wet granulators and dry granulators. Wet granulators are machines that utilize liquid binders to agglomerate powder particles into granules. This process involves mixing the powder with a liquid solution, which acts as a binding agent, and then forcing the mixture through a screen or sieve to form granules. Wet granulation is particularly beneficial for materials that require a high degree of cohesion or when the active ingredient needs to be evenly distributed throughout the granule. This method is commonly used in the pharmaceutical industry, where precise dosage and uniformity are critical. The wet granulation process can also enhance the flowability and compressibility of powders, making them easier to handle and process in subsequent manufacturing steps. On the other hand, dry granulators operate without the use of liquid binders. Instead, they rely on mechanical force to compact powder particles into granules. This process is known as dry compaction or roller compaction. Dry granulation is ideal for materials that are sensitive to moisture or heat, as it eliminates the need for drying steps and reduces the risk of degradation. It is also a more energy-efficient process, as it does not require the additional energy input associated with drying. Dry granulators are commonly used in industries such as chemicals and food processing, where moisture-sensitive materials are prevalent. Both wet and dry granulators have their unique advantages and are chosen based on the specific requirements of the material being processed and the desired characteristics of the final granules. The choice between wet and dry granulation often depends on factors such as the physical and chemical properties of the raw materials, the intended use of the granules, and the production scale. In the Global Round Granule Granulator Market, manufacturers continue to innovate and develop new technologies to improve the efficiency and effectiveness of both wet and dry granulation processes. This includes advancements in machine design, automation, and control systems, which enhance the precision and consistency of granulation. As industries continue to demand higher quality and more efficient production methods, the role of wet and dry granulators in the Global Round Granule Granulator Market is expected to grow, driving further innovation and development in this field.

Mining, Agriculture, Food Processing, Chemical and Pharmaceutical, Cosmetics, Others in the Global Round Granule Granulator Market:

The Global Round Granule Granulator Market finds extensive applications across various industries, including mining, agriculture, food processing, chemical and pharmaceutical, cosmetics, and others. In the mining industry, granulators are used to process minerals and ores into uniform granules, which can improve the efficiency of subsequent processing steps such as smelting or refining. The ability to produce consistent granule sizes is crucial in mining operations, as it ensures optimal material flow and reduces the risk of blockages in processing equipment. In agriculture, granulators are used to produce fertilizers and soil conditioners in granular form. This allows for more precise application and distribution of nutrients, leading to improved crop yields and reduced environmental impact. Granulated fertilizers are also easier to store and transport, making them a preferred choice for farmers and agricultural businesses. In the food processing industry, granulators are used to create uniform granules of ingredients such as sugar, salt, and spices. This ensures consistent flavor and texture in the final product and facilitates easier handling and packaging. Granulation also plays a role in the production of instant food products, where quick solubility and uniformity are essential. In the chemical and pharmaceutical industries, granulators are used to produce granules of active ingredients and excipients, which are then compressed into tablets or capsules. Granulation improves the flowability and compressibility of powders, ensuring accurate dosage and consistent product quality. In the cosmetics industry, granulators are used to produce granules of ingredients such as pigments and exfoliants, which are then incorporated into various cosmetic products. The ability to produce uniform granules is crucial in cosmetics, as it ensures consistent product performance and appearance. Overall, the Global Round Granule Granulator Market plays a vital role in supporting these industries by providing the tools necessary for efficient and effective material processing. As industries continue to evolve and seek more sustainable and efficient production methods, the demand for advanced granulation technology is expected to grow, driving further innovation and development in this field.

Global Round Granule Granulator Market Outlook:

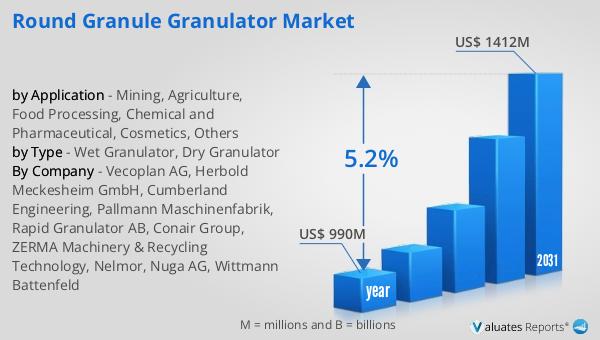

The global market for Round Granule Granulator was valued at approximately $990 million in 2024, and it is anticipated to expand to a revised size of around $1,412 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. This upward trend is indicative of the increasing demand for granulation technology across various industries, driven by the need for efficient and consistent material processing. The market's growth is fueled by advancements in granulation technology, which offer improved performance, energy efficiency, and ease of use. As industries continue to evolve and seek more sustainable and efficient production methods, the demand for advanced granulation technology is expected to grow. The focus on innovation and technological advancement is a key characteristic of this market, as manufacturers strive to develop machines that offer improved performance, energy efficiency, and ease of use. The Global Round Granule Granulator Market plays a vital role in supporting various industries by providing the tools necessary for effective material processing and product development. Overall, the market outlook for Round Granule Granulators is positive, with significant growth expected in the coming years.

| Report Metric | Details |

| Report Name | Round Granule Granulator Market |

| Accounted market size in year | US$ 990 million |

| Forecasted market size in 2031 | US$ 1412 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vecoplan AG, Herbold Meckesheim GmbH, Cumberland Engineering, Pallmann Maschinenfabrik, Rapid Granulator AB, Conair Group, ZERMA Machinery & Recycling Technology, Nelmor, Nuga AG, Wittmann Battenfeld |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |