What is Global Quartz Fabrication Market?

The Global Quartz Fabrication Market is a dynamic and rapidly evolving sector that plays a crucial role in various high-tech industries. Quartz fabrication involves the processing and manufacturing of quartz materials into various forms and products that are essential for numerous applications. Quartz, a naturally occurring mineral, is renowned for its exceptional properties such as high thermal stability, chemical inertness, and optical clarity. These attributes make it an ideal material for use in industries that demand precision and reliability. The market encompasses a wide range of products, including clear and opaque fused quartz, which are used in applications ranging from semiconductors to solar panels. The demand for quartz fabrication is driven by the increasing need for advanced materials in technology-driven sectors. As industries continue to innovate and develop new technologies, the importance of quartz fabrication is expected to grow, making it a vital component of the global industrial landscape. The market is characterized by a high level of competition, with key players striving to enhance their production capabilities and expand their product offerings to meet the diverse needs of their customers.

Clear Fused Quartz, Opaque Fused Quartz in the Global Quartz Fabrication Market:

Clear fused quartz and opaque fused quartz are two primary types of quartz materials used in the Global Quartz Fabrication Market, each with distinct characteristics and applications. Clear fused quartz is known for its exceptional optical clarity and high purity, making it an ideal choice for applications that require transparency and precision. It is produced by melting naturally occurring quartz crystals at high temperatures, resulting in a material that is free from impurities and has excellent thermal and chemical stability. This type of quartz is widely used in the semiconductor industry, where it is essential for the production of high-performance electronic components. Its ability to withstand extreme temperatures and resist chemical corrosion makes it a preferred material for manufacturing semiconductor wafers and other critical components. Additionally, clear fused quartz is used in the production of optical devices, such as lenses and prisms, where its optical clarity and low thermal expansion are crucial for maintaining the accuracy and performance of these devices. On the other hand, opaque fused quartz is characterized by its milky appearance and is produced by adding small amounts of gas or other materials during the melting process. This results in a material that is less transparent but offers enhanced thermal insulation properties. Opaque fused quartz is commonly used in applications where thermal management is a priority, such as in the production of high-temperature furnace linings and crucibles. Its ability to withstand high temperatures without deforming or reacting with other materials makes it an ideal choice for these applications. In the solar industry, opaque fused quartz is used in the manufacturing of photovoltaic cells, where its thermal insulation properties help improve the efficiency and longevity of the cells. Both clear and opaque fused quartz play a vital role in the Global Quartz Fabrication Market, catering to the diverse needs of industries that rely on advanced materials for their operations. As technology continues to advance, the demand for these materials is expected to grow, driving innovation and development in the quartz fabrication sector.

Semiconductor, Optical Device, Solar Industries, Others in the Global Quartz Fabrication Market:

The Global Quartz Fabrication Market finds extensive usage across several key industries, including semiconductors, optical devices, solar industries, and others, each benefiting from the unique properties of quartz materials. In the semiconductor industry, quartz fabrication is indispensable due to the material's high purity and thermal stability. Quartz is used in the production of semiconductor wafers, which are the foundation of electronic devices. The ability of quartz to withstand high temperatures and resist chemical reactions ensures the integrity and performance of these wafers during the manufacturing process. This makes quartz an essential material for producing high-performance electronic components that power modern technology. In the realm of optical devices, quartz's exceptional optical clarity and low thermal expansion make it a preferred material for manufacturing lenses, prisms, and other optical components. These devices require materials that can maintain their shape and clarity under varying environmental conditions, and quartz's properties make it an ideal choice. The precision and reliability of optical devices are crucial in applications ranging from scientific research to telecommunications, where even minor distortions can lead to significant errors. The solar industry also relies heavily on quartz fabrication, particularly in the production of photovoltaic cells. Quartz's thermal insulation properties help improve the efficiency and durability of solar cells, enabling them to convert sunlight into electricity more effectively. As the demand for renewable energy sources continues to rise, the role of quartz in enhancing the performance of solar technologies becomes increasingly important. Beyond these industries, quartz fabrication is used in a variety of other applications, including the production of laboratory equipment, lighting, and even in the aerospace sector. The versatility and reliability of quartz materials make them suitable for a wide range of uses, driving demand across multiple sectors. As industries continue to innovate and develop new technologies, the importance of quartz fabrication is expected to grow, making it a vital component of the global industrial landscape.

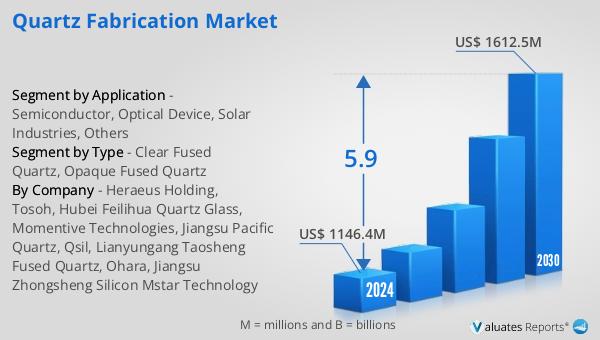

Global Quartz Fabrication Market Outlook:

The global market for Quartz Fabrication was valued at $1,207 million in 2024 and is anticipated to expand to a revised size of $1,787 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. The market is dominated by the top five manufacturers, who collectively hold a significant share exceeding 68%. Among the countries involved in quartz fabrication, China stands out as the largest producer, contributing over 37% to the global production. In terms of product segmentation, clear fused quartz emerges as the most prominent segment, accounting for more than 83% of the market share. This dominance is attributed to its widespread application in industries that demand high purity and optical clarity. When examining the market from an application perspective, the semiconductor industry is the largest consumer, with a substantial share exceeding 70%. This is due to the critical role that quartz plays in the manufacturing of semiconductor wafers and other electronic components. The robust growth of the quartz fabrication market is driven by the increasing demand for advanced materials in technology-driven sectors, highlighting the importance of quartz in supporting innovation and development across various industries.

| Report Metric | Details |

| Report Name | Quartz Fabrication Market |

| Accounted market size in year | US$ 1207 million |

| Forecasted market size in 2031 | US$ 1787 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heraeus Holding, Tosoh, Hubei Feilihua Quartz Glass, Momentive Technologies, Jiangsu Pacific Quartz, Qsil, Lianyungang Taosheng Fused Quartz, Ohara, Jiangsu Zhongsheng Silicon Mstar Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |