What is Global Progressing Cavity Pumping Systems Market?

The Global Progressing Cavity Pumping Systems Market refers to the worldwide industry focused on the production and distribution of progressing cavity pumps. These pumps are unique in their design, featuring a helical rotor that moves within a stator, creating cavities that progress along the pump's length. This design allows for the efficient handling of viscous fluids, slurries, and materials with high solid content. Progressing cavity pumps are highly valued for their ability to provide a steady, non-pulsating flow, making them ideal for applications where precision and consistency are crucial. The market encompasses a wide range of industries, including oil and gas, food and beverage, and wastewater management, where these pumps are used to transport various substances. The global market is driven by the increasing demand for efficient and reliable pumping solutions across these sectors, as well as advancements in pump technology that enhance performance and durability. As industries continue to seek out more efficient and sustainable solutions, the Global Progressing Cavity Pumping Systems Market is expected to grow, offering innovative products that meet the evolving needs of its diverse customer base.

Dosing Pump, Flanged Pump, Hopper Pump, Food Grade, Others in the Global Progressing Cavity Pumping Systems Market:

Progressing cavity pumping systems are versatile and come in various types, each designed to meet specific needs across different industries. Dosing pumps, for instance, are a type of progressing cavity pump that is used for precise fluid metering and dosing applications. They are commonly employed in industries where accurate chemical dosing is critical, such as in water treatment and chemical processing. These pumps ensure that the exact amount of fluid is delivered consistently, which is essential for maintaining the quality and safety of the processes they support. Flanged pumps, on the other hand, are designed with flanges that allow them to be easily connected to piping systems. This design feature makes them suitable for applications where quick and secure connections are necessary, such as in industrial settings where downtime needs to be minimized. Hopper pumps are another variant, characterized by their large hopper inlet, which allows them to handle thick, viscous materials and slurries. These pumps are often used in the food and beverage industry, where they can efficiently transport products like dough, pastes, and other semi-solid materials. Food-grade progressing cavity pumps are specifically designed to meet the stringent hygiene and safety standards required in the food and beverage industry. They are constructed from materials that are safe for contact with food products and are easy to clean, ensuring that they do not contaminate the products they handle. Finally, there are other specialized progressing cavity pumps designed for niche applications, such as those used in the pharmaceutical industry for the precise handling of sensitive fluids. Each type of progressing cavity pump offers unique features and benefits, making them suitable for a wide range of applications across various industries.

Oil & Gas, Food & Beverage, Water & Wastewater Management, Others in the Global Progressing Cavity Pumping Systems Market:

The Global Progressing Cavity Pumping Systems Market finds extensive usage across several key industries, each benefiting from the unique capabilities of these pumps. In the oil and gas sector, progressing cavity pumps are used for the extraction and transportation of crude oil and natural gas. Their ability to handle high-viscosity fluids and slurries makes them ideal for pumping oil from wells, especially in challenging environments where other types of pumps may struggle. These pumps are also used in enhanced oil recovery processes, where their precise flow control helps optimize production rates. In the food and beverage industry, progressing cavity pumps are employed to transport a wide range of products, from liquids to semi-solids. Their gentle pumping action ensures that delicate products, such as fruit purees and dairy products, are not damaged during the transfer process. Additionally, their ability to handle viscous materials makes them suitable for transporting products like chocolate, dough, and sauces. In the water and wastewater management sector, progressing cavity pumps are used for the treatment and transfer of sludge and other waste materials. Their robust design allows them to handle abrasive and corrosive substances, making them ideal for use in harsh environments. These pumps are also used in the dosing of chemicals for water treatment processes, where their precise flow control ensures that the correct amount of chemicals is added to the water. Beyond these industries, progressing cavity pumps are used in a variety of other applications, including mining, chemical processing, and pharmaceuticals, where their ability to handle challenging materials and provide precise flow control is highly valued.

Global Progressing Cavity Pumping Systems Market Outlook:

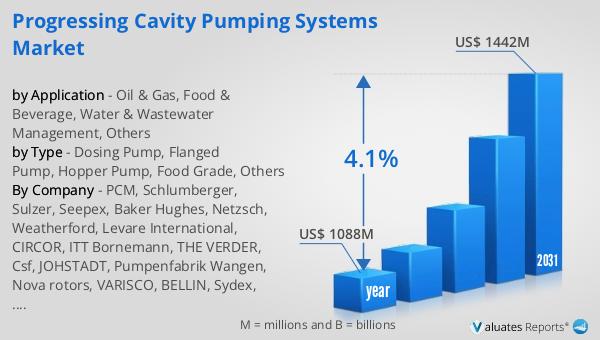

The global market for progressing cavity pumping systems was valued at $1,088 million in 2024 and is anticipated to grow to a revised size of $1,442 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.1% over the forecast period. North America stands out as the largest consumer of progressing cavity pumping systems, accounting for approximately 30% of the global market share. This region's dominance can be attributed to its well-established industrial base and the significant presence of key industries such as oil and gas, food and beverage, and water treatment, all of which rely heavily on these pumps for efficient operations. The steady growth in this market is driven by the increasing demand for reliable and efficient pumping solutions across various sectors, coupled with technological advancements that enhance the performance and durability of these systems. As industries continue to evolve and seek out more sustainable and efficient solutions, the demand for progressing cavity pumping systems is expected to rise, further solidifying their position as a critical component in a wide range of industrial applications.

| Report Metric | Details |

| Report Name | Progressing Cavity Pumping Systems Market |

| Accounted market size in year | US$ 1088 million |

| Forecasted market size in 2031 | US$ 1442 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PCM, Schlumberger, Sulzer, Seepex, Baker Hughes, Netzsch, Weatherford, Levare International, CIRCOR, ITT Bornemann, THE VERDER, Csf, JOHSTADT, Pumpenfabrik Wangen, Nova rotors, VARISCO, BELLIN, Sydex, Lutz Pumpen, mono (NOV), Xinglong Pump, Shanhai Sunshine Pump, Zhejiang Nanchi Pump, Jiangsu Huaqiang Pump, Mingjie Pump, Tianjin Pump Machinery Group Co., Ltd. (CTP), RSP Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |