What is Global Polyoxymethylene (POM) Sales Market?

The Global Polyoxymethylene (POM) Sales Market is a significant segment within the broader plastics industry, focusing on the production and distribution of polyoxymethylene, a high-performance engineering thermoplastic. Known for its excellent mechanical properties, such as high stiffness, low friction, and excellent dimensional stability, POM is widely used in various industries. The market is driven by the demand for durable and lightweight materials that can replace metals in manufacturing processes. POM's resistance to wear and its ability to maintain its properties over a wide temperature range make it a preferred choice for many applications. The market is characterized by a mix of large multinational corporations and smaller regional players, each contributing to the innovation and supply of POM products. The global reach of the market ensures that POM is available to industries worldwide, supporting a wide range of applications from automotive to consumer electronics. As industries continue to seek materials that offer both performance and cost-effectiveness, the Global Polyoxymethylene Sales Market is poised to maintain its importance in the global materials landscape.

in the Global Polyoxymethylene (POM) Sales Market:

Polyoxymethylene (POM) is available in various types, each catering to specific needs and applications across different industries. The most common types of POM are homopolymer and copolymer. Homopolymer POM is known for its high strength, rigidity, and excellent wear resistance. It is often used in applications where these properties are critical, such as in the manufacturing of gears, bearings, and other mechanical components. Homopolymer POM offers superior mechanical properties compared to its copolymer counterpart, making it suitable for high-performance applications. On the other hand, copolymer POM is valued for its enhanced thermal stability and resistance to chemical degradation. This type of POM is often used in environments where exposure to chemicals and varying temperatures is a concern. Copolymer POM is also less prone to porosity, which can be an advantage in applications requiring high precision and surface finish. The choice between homopolymer and copolymer POM often depends on the specific requirements of the application, including factors such as mechanical stress, environmental conditions, and cost considerations. In addition to these primary types, POM can also be modified with various additives to enhance its properties. For example, glass-filled POM offers increased strength and stiffness, making it suitable for applications requiring additional reinforcement. Similarly, lubricated POM grades are available for applications where reduced friction and wear are essential. These modified grades of POM expand the material's versatility, allowing it to meet the diverse needs of different industries. The automotive industry, for instance, often uses glass-filled POM for components that require high strength and durability, such as fuel system parts and interior components. In the electronics industry, lubricated POM is preferred for moving parts in devices where smooth operation is critical. The ability to tailor POM's properties through the use of additives and modifications makes it a highly adaptable material, capable of meeting the evolving demands of modern manufacturing. As industries continue to innovate and seek materials that offer both performance and sustainability, the various types of POM will play a crucial role in supporting these advancements. The Global Polyoxymethylene Sales Market, therefore, not only provides a range of material options but also supports the ongoing development of new applications and technologies.

in the Global Polyoxymethylene (POM) Sales Market:

Polyoxymethylene (POM) finds applications across a wide range of industries due to its unique combination of properties, including high mechanical strength, low friction, and excellent dimensional stability. One of the primary applications of POM is in the automotive industry, where it is used to manufacture various components such as fuel system parts, interior and exterior trims, and mechanical gears. The material's ability to withstand high temperatures and resist wear makes it ideal for automotive applications that require durability and reliability. In the electronics industry, POM is used in the production of precision parts such as connectors, switches, and housings. Its excellent electrical insulating properties and resistance to moisture make it suitable for electronic components that require high performance and reliability. POM's low friction and wear resistance also make it an ideal material for moving parts in electronic devices, ensuring smooth operation and longevity. The consumer goods industry also benefits from the use of POM, particularly in the production of household appliances and personal care products. POM's durability and resistance to chemicals make it suitable for components that are exposed to harsh conditions, such as dishwasher parts and razor handles. In the medical industry, POM is used in the manufacturing of medical devices and components, including surgical instruments and drug delivery systems. The material's biocompatibility and resistance to sterilization processes make it a preferred choice for medical applications that require high precision and safety. Additionally, POM is used in the production of industrial machinery and equipment, where its mechanical properties and resistance to wear are essential for the performance and longevity of components. The versatility of POM allows it to be used in a wide range of applications, supporting the needs of various industries and contributing to the development of innovative products and technologies. As industries continue to seek materials that offer both performance and sustainability, POM's role in supporting these advancements will remain significant. The Global Polyoxymethylene Sales Market, therefore, not only provides a range of material options but also supports the ongoing development of new applications and technologies.

Global Polyoxymethylene (POM) Sales Market Outlook:

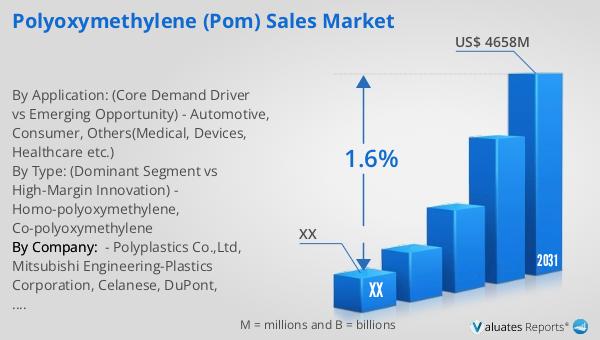

In 2024, the global market for Polyoxymethylene (POM) was valued at approximately $4,174 million. Looking ahead, projections indicate that by 2031, the market is expected to grow to an adjusted size of around $4,658 million, reflecting a compound annual growth rate (CAGR) of 1.6% during the forecast period from 2025 to 2031. This growth trajectory underscores the steady demand for POM across various industries, driven by its unique properties and versatility. The market is dominated by the top five global players, who collectively hold about 60% of the market share, highlighting the competitive landscape and the significant influence of these key players in shaping market trends and innovations. Among the different product segments within the POM market, Copolyoxymethylene stands out as the largest, accounting for approximately 90% of the market share. This dominance can be attributed to Copolyoxymethylene's enhanced thermal stability and resistance to chemical degradation, making it a preferred choice for applications that require durability and reliability. The market's growth is supported by the continuous demand for high-performance materials that can replace traditional metals and other plastics in various applications, from automotive to consumer electronics. As industries continue to evolve and seek materials that offer both performance and cost-effectiveness, the Global Polyoxymethylene Sales Market is poised to maintain its importance in the global materials landscape.

| Report Metric | Details |

| Report Name | Polyoxymethylene (POM) Sales Market |

| Forecasted market size in 2031 | US$ 4658 million |

| CAGR | 1.6% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Polyplastics Co.,Ltd, Mitsubishi Engineering-Plastics Corporation, Celanese, DuPont, YUNTIANHUA, BLUESTAR, HENAN ENERGY AND CHEMICAL INDUSTRY, Shenhua Ningxia Coal Industry Group Co., Ltd, CNOOC Tianye Chemical Co., Ltd., BASF, Formosa Plastics Corporation, Asahi Kasei, KOLON, KEP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |