What is Global Polyimide (PI) Insulation Varnish Market?

The Global Polyimide (PI) Insulation Varnish Market is a specialized segment within the broader insulation materials industry, focusing on the production and application of polyimide-based varnishes. These varnishes are renowned for their exceptional thermal stability, mechanical strength, and electrical insulation properties, making them ideal for high-performance applications. Polyimide insulation varnishes are primarily used to coat wires, cables, and other components that require reliable insulation under extreme conditions. The market is driven by the increasing demand for advanced electronic devices, electric vehicles, and aerospace technologies, all of which require materials that can withstand high temperatures and harsh environments. As industries continue to push the boundaries of technology, the need for robust insulation solutions like polyimide varnishes is expected to grow. This market is characterized by continuous innovation, with manufacturers investing in research and development to enhance the performance and versatility of their products. The global reach of this market is expanding, with significant growth opportunities in regions with burgeoning electronics and automotive industries. Overall, the Global Polyimide (PI) Insulation Varnish Market plays a crucial role in supporting the advancement of modern technologies by providing essential insulation solutions.

Thermoplastic Varnish, Thermosetting Varnish in the Global Polyimide (PI) Insulation Varnish Market:

Thermoplastic and thermosetting varnishes are two primary types of polyimide insulation varnishes, each with distinct characteristics and applications within the Global Polyimide (PI) Insulation Varnish Market. Thermoplastic varnishes are known for their ability to soften when heated and harden upon cooling, allowing for reprocessing and reshaping. This property makes them highly versatile and suitable for applications where flexibility and recyclability are important. Thermoplastic varnishes are often used in industries that require materials to be molded or reshaped, such as in the manufacturing of flexible electronics and certain automotive components. Their ease of processing and ability to be reworked make them a popular choice for applications that demand adaptability and customization. On the other hand, thermosetting varnishes undergo a chemical reaction when heated, resulting in a rigid and inflexible structure that cannot be reshaped or reprocessed. This characteristic makes them ideal for applications that require high thermal stability and mechanical strength. Thermosetting varnishes are commonly used in environments where components are exposed to extreme temperatures and mechanical stress, such as in aerospace and high-performance electronics. Their ability to maintain structural integrity under harsh conditions makes them indispensable in critical applications where reliability is paramount. The choice between thermoplastic and thermosetting varnishes depends on the specific requirements of the application, including factors such as temperature resistance, mechanical properties, and ease of processing. In the Global Polyimide (PI) Insulation Varnish Market, manufacturers offer a range of products to cater to the diverse needs of different industries. Innovations in formulation and processing techniques continue to expand the capabilities of both thermoplastic and thermosetting varnishes, enabling them to meet the evolving demands of modern technologies. As industries strive for greater efficiency and performance, the role of polyimide insulation varnishes becomes increasingly important, driving further research and development in this field. The market for these varnishes is characterized by a dynamic interplay between technological advancements and industry requirements, with manufacturers constantly seeking to enhance the properties and applications of their products. Overall, the distinction between thermoplastic and thermosetting varnishes highlights the versatility and adaptability of polyimide insulation varnishes, making them a vital component in the advancement of various high-tech industries.

Semiconductors, Display Panels, Electric Vehicles, Aerospace, Others in the Global Polyimide (PI) Insulation Varnish Market:

The Global Polyimide (PI) Insulation Varnish Market finds extensive usage across several high-tech industries, including semiconductors, display panels, electric vehicles, aerospace, and others. In the semiconductor industry, polyimide insulation varnishes are crucial for ensuring the reliability and performance of electronic components. These varnishes provide excellent thermal stability and electrical insulation, protecting sensitive semiconductor devices from heat and electrical interference. As the demand for smaller and more powerful electronic devices continues to grow, the need for advanced insulation solutions like polyimide varnishes becomes increasingly important. In the display panel industry, polyimide varnishes are used to enhance the durability and performance of flexible displays. Their ability to withstand high temperatures and mechanical stress makes them ideal for use in the production of flexible OLED and LCD panels, which are becoming increasingly popular in consumer electronics. The electric vehicle industry also benefits from the use of polyimide insulation varnishes, as they provide the necessary thermal and electrical insulation for high-performance batteries and electric motors. As the demand for electric vehicles continues to rise, the need for reliable insulation solutions that can withstand the rigors of automotive applications becomes more critical. In the aerospace industry, polyimide varnishes are used to protect critical components from extreme temperatures and mechanical stress. Their ability to maintain structural integrity under harsh conditions makes them indispensable in the production of aircraft and spacecraft components. Additionally, polyimide varnishes are used in other industries, such as telecommunications and renewable energy, where reliable insulation is essential for the performance and longevity of electronic components. Overall, the Global Polyimide (PI) Insulation Varnish Market plays a vital role in supporting the advancement of various high-tech industries by providing essential insulation solutions that enhance the performance and reliability of electronic components.

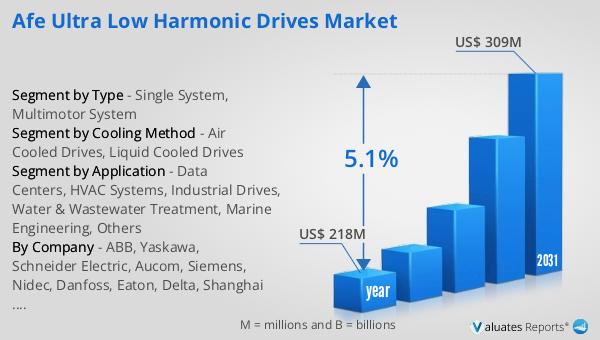

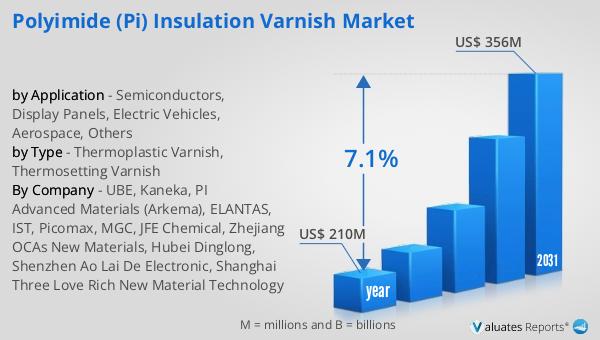

Global Polyimide (PI) Insulation Varnish Market Outlook:

The global market for Polyimide (PI) Insulation Varnish was valued at $210 million in 2024 and is anticipated to expand to a revised size of $356 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.1% over the forecast period. This growth trajectory underscores the increasing demand for high-performance insulation materials across various industries. The rising adoption of advanced electronic devices, electric vehicles, and aerospace technologies is driving the need for reliable insulation solutions that can withstand extreme conditions. Polyimide insulation varnishes, with their exceptional thermal stability and electrical insulation properties, are well-suited to meet these demands. As industries continue to innovate and push the boundaries of technology, the role of polyimide varnishes becomes increasingly important. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the performance and versatility of these varnishes. Manufacturers are investing in new formulations and processing techniques to cater to the evolving needs of different industries. The global reach of the Polyimide (PI) Insulation Varnish Market is expanding, with significant growth opportunities in regions with burgeoning electronics and automotive industries. Overall, the market outlook for Polyimide (PI) Insulation Varnish is positive, with strong growth prospects driven by the increasing demand for advanced insulation solutions in high-tech industries.

| Report Metric | Details |

| Report Name | Polyimide (PI) Insulation Varnish Market |

| Accounted market size in year | US$ 210 million |

| Forecasted market size in 2031 | US$ 356 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | UBE, Kaneka, PI Advanced Materials (Arkema), ELANTAS, IST, Picomax, MGC, JFE Chemical, Zhejiang OCAs New Materials, Hubei Dinglong, Shenzhen Ao Lai De Electronic, Shanghai Three Love Rich New Material Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |