What is Global Phenolic Foam Board Sales Market?

The Global Phenolic Foam Board Sales Market refers to the worldwide trade and distribution of phenolic foam boards, which are specialized insulation materials known for their excellent fire resistance, thermal insulation, and moisture resistance properties. These boards are primarily used in the construction industry for insulating buildings, ensuring energy efficiency, and enhancing safety standards. Phenolic foam boards are made from phenolic resins, which are known for their low thermal conductivity and high structural integrity. The market for these boards is driven by the increasing demand for energy-efficient buildings and stringent fire safety regulations across various regions. As urbanization and industrialization continue to rise, the need for effective insulation solutions becomes more critical, thereby boosting the demand for phenolic foam boards. The market is characterized by a diverse range of products catering to different insulation needs, with manufacturers focusing on innovation and sustainability to meet the evolving demands of consumers. The growth of this market is also supported by advancements in manufacturing technologies, which have improved the quality and performance of phenolic foam boards, making them a preferred choice for modern construction projects.

in the Global Phenolic Foam Board Sales Market:

Phenolic foam boards come in various types, each designed to meet specific customer needs based on the Global Phenolic Foam Board Sales Market. One of the most common types is the standard phenolic foam board, which is widely used for general insulation purposes in residential and commercial buildings. These boards are valued for their excellent thermal insulation properties, which help in reducing energy consumption and maintaining comfortable indoor temperatures. Another type is the high-density phenolic foam board, which offers enhanced structural strength and is often used in applications where additional load-bearing capacity is required. This type is particularly popular in industrial settings and for roofing applications where durability is a key concern. There are also phenolic foam boards with specialized coatings or facings, such as aluminum foil or fiberglass, which provide additional benefits like improved moisture resistance or enhanced fire retardancy. These coated boards are often used in environments with high humidity or where fire safety is a critical consideration. Additionally, there are phenolic foam boards designed for specific applications, such as HVAC systems, where they are used to insulate ductwork and improve energy efficiency. These boards are typically thinner and more flexible, allowing for easy installation in confined spaces. Another specialized type is the phenolic foam board with acoustic properties, which is used in environments where noise reduction is important, such as recording studios or office buildings. These boards are designed to absorb sound waves, thereby reducing noise levels and improving acoustic comfort. Furthermore, some phenolic foam boards are designed with environmental considerations in mind, using eco-friendly materials and manufacturing processes to reduce their carbon footprint. These sustainable boards are gaining popularity among environmentally conscious consumers and businesses looking to reduce their impact on the environment. Overall, the variety of phenolic foam boards available in the market allows customers to choose the most suitable product for their specific insulation needs, whether it be for thermal insulation, fire safety, moisture resistance, or acoustic comfort. Manufacturers continue to innovate and develop new types of phenolic foam boards to meet the evolving demands of the market, ensuring that there is a solution for every application.

in the Global Phenolic Foam Board Sales Market:

Phenolic foam boards are utilized in a wide range of applications, reflecting their versatility and effectiveness as an insulation material in the Global Phenolic Foam Board Sales Market. One of the primary applications is in the construction industry, where these boards are used to insulate walls, roofs, and floors of residential and commercial buildings. Their excellent thermal insulation properties help in reducing energy consumption, leading to lower heating and cooling costs and contributing to the overall energy efficiency of buildings. In addition to thermal insulation, phenolic foam boards are also used for their fire-resistant properties, making them an ideal choice for applications where fire safety is a priority. This includes high-rise buildings, hospitals, schools, and other public buildings where stringent fire safety regulations are in place. Another significant application of phenolic foam boards is in the HVAC (Heating, Ventilation, and Air Conditioning) industry. These boards are used to insulate ductwork, preventing heat loss or gain and improving the overall efficiency of HVAC systems. By maintaining the desired temperature within the ducts, phenolic foam boards help in reducing energy consumption and ensuring optimal performance of heating and cooling systems. Furthermore, phenolic foam boards are used in the transportation industry, particularly in the manufacturing of vehicles such as buses, trains, and airplanes. Their lightweight nature and excellent insulation properties make them suitable for use in vehicle interiors, where they help in maintaining comfortable temperatures and reducing noise levels. In the industrial sector, phenolic foam boards are used for insulating pipes, tanks, and other equipment, providing protection against extreme temperatures and preventing energy loss. This is particularly important in industries such as oil and gas, chemical processing, and food and beverage, where maintaining specific temperature conditions is crucial for operational efficiency and product quality. Additionally, phenolic foam boards are used in the packaging industry, where they provide thermal insulation and protection for temperature-sensitive products during transportation and storage. This includes perishable goods, pharmaceuticals, and electronic components that require controlled temperature conditions to maintain their quality and integrity. Overall, the diverse applications of phenolic foam boards highlight their importance as a versatile and effective insulation material, catering to the needs of various industries and contributing to energy efficiency, safety, and sustainability.

Global Phenolic Foam Board Sales Market Outlook:

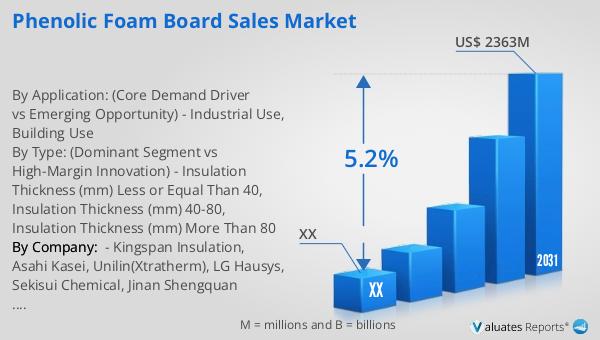

In 2024, the global market for Phenolic Foam Boards was valued at approximately $1,665 million. Looking ahead, projections indicate that by 2031, this market is expected to grow to an adjusted size of around $2,363 million, reflecting a compound annual growth rate (CAGR) of 5.2% during the forecast period from 2025 to 2031. This growth underscores the increasing demand for phenolic foam boards, driven by their superior insulation properties and fire resistance, which are highly valued in various industries. Notably, the market is dominated by the top three manufacturers, who collectively hold a market share exceeding 60%. This concentration of market power highlights the competitive landscape and the influence of leading companies in shaping market trends and innovations. In terms of product segmentation, insulation boards with a thickness of 40 mm or less represent the largest segment, accounting for over 60% of the market share. This preference for thinner boards is likely due to their versatility and ease of installation, making them suitable for a wide range of applications in both residential and commercial settings. As the market continues to evolve, manufacturers are expected to focus on product innovation and sustainability to meet the growing demand for energy-efficient and environmentally friendly insulation solutions.

| Report Metric | Details |

| Report Name | Phenolic Foam Board Sales Market |

| Forecasted market size in 2031 | US$ 2363 million |

| CAGR | 5.2% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Kingspan Insulation, Asahi Kasei, Unilin(Xtratherm), LG Hausys, Sekisui Chemical, Jinan Shengquan Group, Tenlead, Guibao |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |