What is Global Paper-Backing Abrasive Adhesive Discs Sales Market?

The Global Paper-Backing Abrasive Adhesive Discs Sales Market is a specialized segment within the broader abrasives industry, focusing on products that are essential for various finishing and surface preparation tasks. These discs are made by attaching abrasive grains to a paper backing, which is then coated with an adhesive to ensure the grains remain in place during use. This market is driven by the demand for efficient and effective surface finishing solutions across multiple industries, including automotive, construction, and manufacturing. The discs are used for sanding, polishing, and finishing surfaces to achieve the desired smoothness or texture. The market's growth is influenced by technological advancements in abrasive materials and the increasing need for high-quality surface finishes in various applications. As industries continue to evolve, the demand for these discs is expected to rise, driven by the need for precision and efficiency in surface preparation tasks. The market is characterized by a diverse range of products, catering to different needs and preferences, making it a dynamic and competitive space.

in the Global Paper-Backing Abrasive Adhesive Discs Sales Market:

In the Global Paper-Backing Abrasive Adhesive Discs Sales Market, various types of discs are utilized by customers based on their specific needs and applications. One of the most common types is the adhesive-backed sandpaper, which is favored for its versatility and ease of use. This type of disc is primarily used for sanding wood, metal, and plastic surfaces, making it a staple in woodworking and metalworking industries. The adhesive backing allows for quick attachment and removal from sanding machines, enhancing productivity and efficiency. Another popular type is the hook and loop discs, which offer the advantage of easy disc changes and are often used in applications where frequent grit changes are necessary. These discs are particularly useful in automotive refinishing and furniture manufacturing, where different levels of abrasiveness are required for various stages of the finishing process. Additionally, there are fiber-backed discs, which are known for their durability and strength. These discs are typically used in heavy-duty applications such as grinding and deburring metal surfaces. The fiber backing provides extra support, allowing the discs to withstand high pressure and heat during use. Furthermore, there are film-backed abrasive discs, which offer a smooth and consistent finish. These discs are often used in applications where a high-quality finish is essential, such as in the electronics and aerospace industries. The film backing provides a uniform surface for the abrasive grains, resulting in a more even and precise finish. Each type of disc is designed to meet specific requirements, and the choice of disc depends on factors such as the material being worked on, the desired finish, and the equipment being used. As the market continues to grow, manufacturers are constantly innovating to develop new types of discs that offer improved performance and efficiency. This includes the development of discs with advanced abrasive materials, such as ceramic and diamond, which offer superior cutting power and longevity. These innovations are driven by the increasing demand for high-performance abrasives that can meet the challenges of modern manufacturing and finishing processes. Overall, the variety of discs available in the market ensures that customers can find the right product to meet their specific needs, whether they are looking for a disc that offers quick and easy changes, durability, or a high-quality finish.

in the Global Paper-Backing Abrasive Adhesive Discs Sales Market:

The Global Paper-Backing Abrasive Adhesive Discs Sales Market serves a wide range of applications across various industries, each with its unique requirements and challenges. In the automotive industry, these discs are extensively used for tasks such as paint preparation, rust removal, and surface finishing. The ability to achieve a smooth and even surface is crucial in automotive refinishing, where the quality of the finish can significantly impact the overall appearance and value of the vehicle. Similarly, in the woodworking industry, these discs are used for sanding and finishing wood surfaces, ensuring a smooth and polished finish that enhances the natural beauty of the wood. The construction industry also relies on these discs for tasks such as drywall sanding and surface preparation, where a smooth and even surface is essential for achieving a professional finish. In the metalworking industry, these discs are used for grinding, deburring, and polishing metal surfaces, where precision and efficiency are critical. The ability to quickly and effectively remove material while achieving a high-quality finish is essential in this industry, where time and cost efficiency are paramount. Additionally, these discs are used in the electronics industry for tasks such as circuit board preparation and component finishing, where a precise and consistent finish is required to ensure the proper functioning of electronic components. The aerospace industry also utilizes these discs for surface preparation and finishing tasks, where the quality of the finish can impact the performance and safety of aircraft components. The versatility and effectiveness of these discs make them an essential tool in a wide range of applications, where achieving a high-quality finish is crucial. As industries continue to evolve and demand higher standards of quality and efficiency, the demand for these discs is expected to grow, driven by the need for precision and performance in surface preparation and finishing tasks.

Global Paper-Backing Abrasive Adhesive Discs Sales Market Outlook:

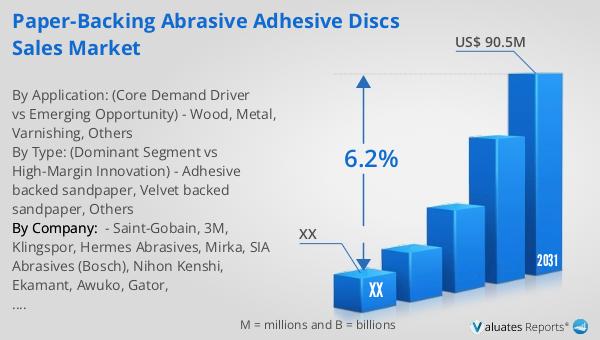

The global market for Paper-Backing Abrasive Adhesive Discs was valued at approximately $59.7 million in 2024, and it is projected to expand to around $90.5 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.2% during the forecast period from 2025 to 2031. The market is characterized by a competitive landscape, with the top four manufacturers collectively holding nearly 35% of the market share. Among the various product segments, adhesive-backed sandpaper emerges as the largest, accounting for nearly 60% of the market. This segment's dominance can be attributed to its widespread use across multiple industries, including automotive, woodworking, and metalworking, where it is valued for its versatility and ease of use. The adhesive backing allows for quick attachment and removal, enhancing productivity and efficiency in various applications. As the market continues to grow, manufacturers are focusing on innovation and the development of new products to meet the evolving needs of customers. This includes the introduction of advanced abrasive materials and improved backing technologies that offer enhanced performance and durability. The market's growth is driven by the increasing demand for high-quality surface finishes and the need for efficient and effective surface preparation solutions across various industries. As industries continue to evolve and demand higher standards of quality and efficiency, the market for paper-backing abrasive adhesive discs is expected to continue its upward trajectory, driven by the need for precision and performance in surface preparation and finishing tasks.

| Report Metric | Details |

| Report Name | Paper-Backing Abrasive Adhesive Discs Sales Market |

| Forecasted market size in 2031 | US$ 90.5 million |

| CAGR | 6.2% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Saint-Gobain, 3M, Klingspor, Hermes Abrasives, Mirka, SIA Abrasives (Bosch), Nihon Kenshi, Ekamant, Awuko, Gator, Sankyo-Rikagaku, Carborundum Universal, Keystone Abrasives, Kovax, Dongguan Jinyang, Sunmight, Guangdong Shunhui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |