What is Global Onboard Oxygen Generation System Market?

The Global Onboard Oxygen Generation System (OBOGS) Market is a specialized segment within the aerospace industry that focuses on the development and deployment of systems designed to produce oxygen onboard aircraft. These systems are crucial for ensuring a continuous supply of oxygen to pilots and passengers, especially at high altitudes where atmospheric oxygen levels are insufficient. OBOGS technology is primarily used in military and commercial aviation to replace traditional oxygen storage methods, such as compressed oxygen cylinders, which can be bulky and require regular maintenance and refilling. The market for these systems is driven by the increasing demand for advanced aviation safety measures, the need for efficient and lightweight oxygen supply solutions, and the growing number of aircraft in operation worldwide. As aviation technology continues to evolve, the OBOGS market is expected to expand, offering innovative solutions that enhance the safety and efficiency of air travel. The systems are designed to be reliable, cost-effective, and capable of operating under various environmental conditions, making them an essential component of modern aircraft design and operation. The market's growth is also supported by advancements in technology that improve the performance and reliability of these systems, ensuring they meet the stringent safety standards required in the aviation industry.

Chemical Oxygen Generation System, Molecular Sieve Oxygen Generation System, Compressed Oxygen Cylinder System, Membrane Separation Oxygen Generation System in the Global Onboard Oxygen Generation System Market:

The Global Onboard Oxygen Generation System Market encompasses several key technologies, each with its unique mechanisms and applications. The Chemical Oxygen Generation System is one of the traditional methods used in oxygen generation. It involves a chemical reaction that produces oxygen, typically through the decomposition of sodium chlorate or other oxygen-rich compounds. This system is often used in emergency situations due to its ability to produce oxygen quickly and without the need for external power sources. However, it has limitations in terms of the duration of oxygen supply and the need for chemical replenishment after use. The Molecular Sieve Oxygen Generation System, on the other hand, utilizes a process called pressure swing adsorption (PSA) to separate oxygen from other gases in the air. This system is highly efficient and can provide a continuous supply of oxygen, making it suitable for both military and commercial aviation applications. It works by passing compressed air through a molecular sieve that selectively adsorbs nitrogen, allowing oxygen to pass through as the primary output. The Compressed Oxygen Cylinder System is a more traditional approach, involving the storage of oxygen in high-pressure cylinders. While reliable, this system requires regular maintenance and refilling, which can be logistically challenging, especially for long-duration flights. Lastly, the Membrane Separation Oxygen Generation System employs selective permeable membranes to separate oxygen from other gases. This system is valued for its simplicity and low maintenance requirements, as it does not involve moving parts or complex chemical reactions. Each of these systems has its advantages and limitations, and the choice of system often depends on the specific requirements of the aircraft and the operational environment. The ongoing advancements in these technologies are aimed at improving efficiency, reducing weight, and enhancing the overall reliability of onboard oxygen generation systems, thereby supporting the growth of the Global Onboard Oxygen Generation System Market.

Military Aviation, Civil Aviation in the Global Onboard Oxygen Generation System Market:

The usage of Global Onboard Oxygen Generation Systems in military and civil aviation is critical for ensuring the safety and operational efficiency of aircraft. In military aviation, these systems are essential for fighter jets and other high-performance aircraft that operate at altitudes where atmospheric oxygen is insufficient for human survival. The ability to generate oxygen onboard allows military aircraft to undertake long-duration missions without the need for frequent refueling or oxygen replenishment stops. This capability is crucial for maintaining operational readiness and flexibility in various combat scenarios. Additionally, onboard oxygen generation systems enhance the safety of military personnel by providing a reliable and continuous supply of oxygen, even in the event of cabin depressurization or other emergencies. In civil aviation, onboard oxygen generation systems are increasingly being adopted to improve passenger safety and comfort. Commercial airlines are integrating these systems into their aircraft to ensure a steady supply of oxygen, particularly on long-haul flights that reach high altitudes. The use of onboard oxygen generation systems in civil aviation also reduces the logistical challenges associated with storing and maintaining large quantities of compressed oxygen cylinders. This not only enhances the efficiency of airline operations but also contributes to reducing the overall weight of the aircraft, leading to fuel savings and lower operational costs. Furthermore, the adoption of these systems aligns with the industry's focus on sustainability and reducing the environmental impact of air travel. By minimizing the need for chemical-based oxygen generation and reducing the reliance on traditional oxygen storage methods, onboard oxygen generation systems support the aviation industry's efforts to achieve greener and more sustainable operations. Overall, the integration of onboard oxygen generation systems in both military and civil aviation represents a significant advancement in aviation safety and efficiency, contributing to the growth and development of the Global Onboard Oxygen Generation System Market.

Global Onboard Oxygen Generation System Market Outlook:

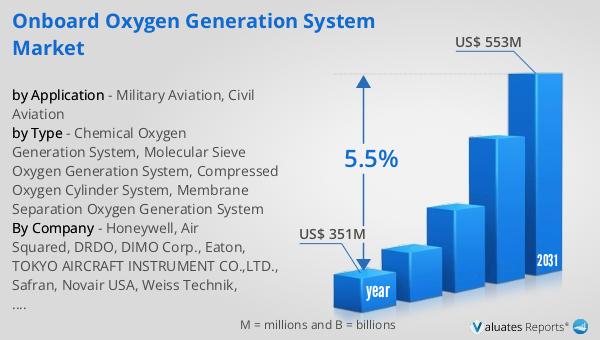

The global market for Onboard Oxygen Generation Systems was valued at $351 million in 2024, with projections indicating a growth to $553 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.5% over the forecast period. The increasing demand for advanced oxygen generation systems in both military and civil aviation is a key driver of this market expansion. As the aviation industry continues to evolve, there is a growing emphasis on enhancing safety measures and improving operational efficiency. Onboard oxygen generation systems play a crucial role in achieving these objectives by providing a reliable and continuous supply of oxygen, reducing the need for traditional oxygen storage methods, and minimizing the logistical challenges associated with oxygen replenishment. The market's growth is also supported by technological advancements that enhance the performance and reliability of these systems, ensuring they meet the stringent safety standards required in the aviation industry. As a result, the Global Onboard Oxygen Generation System Market is expected to continue its upward trajectory, driven by the increasing adoption of these systems in both military and civil aviation applications. The ongoing focus on sustainability and reducing the environmental impact of air travel further supports the market's growth, as onboard oxygen generation systems offer a more efficient and environmentally friendly alternative to traditional oxygen storage methods.

| Report Metric | Details |

| Report Name | Onboard Oxygen Generation System Market |

| Accounted market size in year | US$ 351 million |

| Forecasted market size in 2031 | US$ 553 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Honeywell, Air Squared, DRDO, DIMO Corp., Eaton, TOKYO AIRCRAFT INSTRUMENT CO.,LTD., Safran, Novair USA, Weiss Technik, D.Gillette Industrial Services, Inc., Hatchery International, Treadwell Corporation, Aithre, ProjectsTiger, Collins Aerospace |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |