What is Global Non-Destructive Testing Equipment (NDTE) Sales Market?

The Global Non-Destructive Testing Equipment (NDTE) Sales Market is a rapidly evolving sector that focuses on the sale and distribution of equipment used to evaluate the properties of materials, components, or systems without causing damage. This market is crucial for industries that require rigorous testing to ensure safety, reliability, and compliance with standards, such as aerospace, automotive, construction, and manufacturing. Non-destructive testing (NDT) methods are essential because they allow for the inspection and analysis of materials without compromising their integrity, which is vital for maintaining the longevity and safety of products. The market encompasses a wide range of testing equipment, including ultrasonic, radiographic, magnetic particle, and eddy current testing devices. As industries continue to prioritize safety and quality, the demand for advanced NDTE is expected to grow, driven by technological advancements and the need for more efficient and accurate testing solutions. This market not only supports the operational efficiency of various industries but also plays a significant role in reducing costs associated with material failures and accidents. The global reach of this market indicates its importance across different regions, adapting to the specific needs and regulations of each area.

in the Global Non-Destructive Testing Equipment (NDTE) Sales Market:

The Global Non-Destructive Testing Equipment (NDTE) Sales Market offers a diverse array of testing methods, each tailored to meet the specific needs of various industries. Ultrasonic testing is one of the most prevalent types, utilizing high-frequency sound waves to detect imperfections in materials. This method is particularly favored in industries like aerospace and automotive, where precision is paramount. Radiographic testing, which employs X-rays or gamma rays, is another critical method used to inspect the internal structure of components. This technique is invaluable in sectors such as construction and manufacturing, where internal defects can lead to catastrophic failures. Magnetic particle testing is widely used in the detection of surface and near-surface discontinuities in ferromagnetic materials. This method is often employed in the automotive and construction industries to ensure the integrity of critical components. Eddy current testing, which uses electromagnetic induction to detect flaws, is particularly useful for inspecting conductive materials. It is commonly used in the aerospace industry to inspect aircraft components for cracks and corrosion. Liquid penetrant testing is another widely used method, especially in the detection of surface-breaking defects in non-porous materials. This technique is simple yet effective, making it a popular choice in various industries, including manufacturing and construction. Visual inspection, although the most basic form of NDT, remains a fundamental method used across all industries. It involves the direct observation of a component or structure to identify visible defects. Despite its simplicity, visual inspection is often the first step in the NDT process and is crucial for identifying areas that require further testing. The choice of testing method depends on several factors, including the type of material, the nature of the defect, and the specific requirements of the industry. As technology advances, new methods and equipment are continually being developed, offering more efficient and accurate testing solutions. The integration of digital technologies, such as automated inspection systems and advanced data analysis tools, is also transforming the NDTE market, enabling more precise and reliable testing outcomes. The global nature of this market means that testing methods must also adapt to the varying standards and regulations of different regions, ensuring that industries worldwide can maintain the highest levels of safety and quality.

in the Global Non-Destructive Testing Equipment (NDTE) Sales Market:

The applications of Global Non-Destructive Testing Equipment (NDTE) are vast and varied, spanning multiple industries that require stringent quality control and safety measures. In the aerospace industry, NDTE is crucial for ensuring the safety and reliability of aircraft components. Testing methods such as ultrasonic and eddy current testing are commonly used to inspect critical parts for defects that could compromise the structural integrity of an aircraft. The automotive industry also relies heavily on NDTE to ensure the safety and performance of vehicles. Techniques like magnetic particle and radiographic testing are used to inspect components such as engines, transmissions, and suspension systems for defects. In the construction industry, NDTE is used to assess the integrity of structures such as bridges, buildings, and pipelines. Methods like radiographic and ultrasonic testing are employed to detect flaws in welds and other critical areas that could lead to structural failures. The manufacturing industry uses NDTE to ensure the quality of products and components before they reach the market. Techniques such as liquid penetrant and visual inspection are commonly used to detect surface defects and ensure that products meet the required standards. The energy sector, including oil and gas, also relies on NDTE to inspect pipelines, pressure vessels, and other critical infrastructure for defects that could lead to leaks or failures. The versatility of NDTE makes it an essential tool for maintaining safety and quality across a wide range of applications. As industries continue to evolve and prioritize safety and efficiency, the demand for advanced NDTE solutions is expected to grow. The integration of digital technologies and automated inspection systems is also enhancing the capabilities of NDTE, enabling more accurate and efficient testing processes. The global reach of the NDTE market means that these applications must also adapt to the specific needs and regulations of different regions, ensuring that industries worldwide can maintain the highest levels of safety and quality.

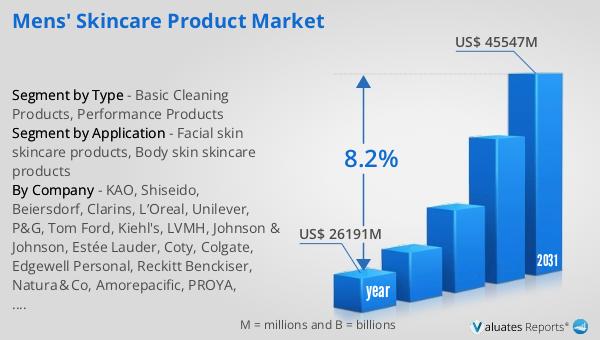

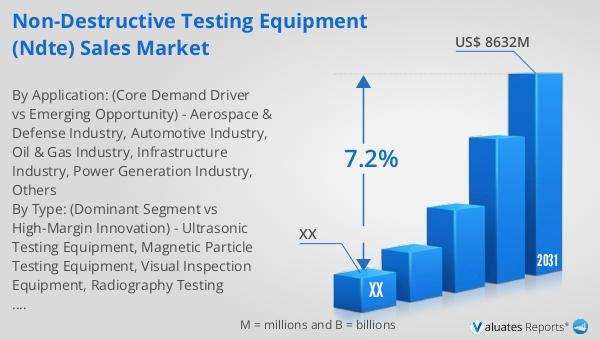

Global Non-Destructive Testing Equipment (NDTE) Sales Market Outlook:

The outlook for the Global Non-Destructive Testing Equipment (NDTE) market indicates significant growth potential. In 2024, the market was valued at approximately $5,331 million, and it is projected to expand to around $8,632 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.2% during the forecast period from 2025 to 2031. The market is dominated by the top five global players, who collectively hold about 40% of the market share. North America is currently the largest market, accounting for approximately 33% of the total market share, followed by Europe and the Asia-Pacific region, which together make up about 60% of the market. Among the various types of NDTE, ultrasonic testing equipment is the largest segment, representing about 30% of the market. This growth is driven by the increasing demand for advanced testing solutions across various industries, as well as the continuous development of new technologies that enhance the efficiency and accuracy of non-destructive testing methods. The market's expansion is also supported by the growing emphasis on safety and quality in industries such as aerospace, automotive, construction, and manufacturing. As these industries continue to evolve and prioritize safety and efficiency, the demand for NDTE is expected to rise, further driving the market's growth.

| Report Metric | Details |

| Report Name | Non-Destructive Testing Equipment (NDTE) Sales Market |

| Forecasted market size in 2031 | US$ 8632 million |

| CAGR | 7.2% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Zeiss, Fujifilm, General Electric, Shimadzu, Comet Group, Spellman, Olympus Corporation, Teledyne, Rigaku, Nikon, Werth, Marietta, VisiConsult, SEC, Vidisco, QSA Global, Sigray, Aolong Group, Unicomp Technology, Dandong NDT Equipment, Sanying Precision Instruments, SXRAY, Dothing Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |